The Method of Macromolecular Electrolyte to Improve the Water Absorption of Neutral Hydrogel

A hydrogel and electrolyte technology, which is applied in the field of polymer materials, can solve the problems of fragility, reduced strength of neutral hydrogel, low water absorption and swelling performance of neutral hydrogel, etc., and achieves high water absorption, easy operation, The effect of great application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

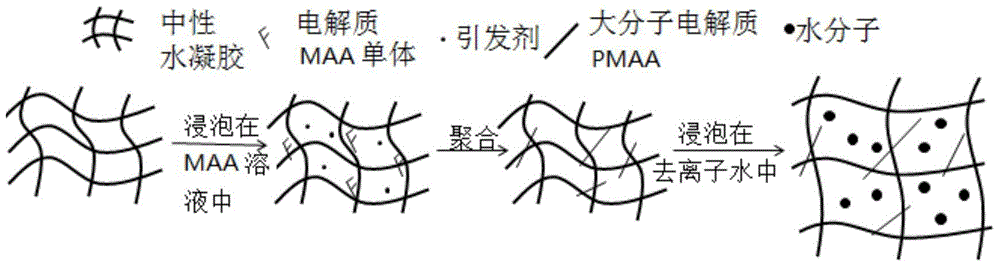

Method used

Image

Examples

Embodiment 1

[0046] Step 1: Soak the neutral PAAm hydrogel of the sample of Comparative Example 1 in a mixed solution of 0.3mol / L methacrylic acid (MAA) and 0.001mol / L KA, and soak in the dark for 1 day;

[0047] Step 2: Take out the neutral PAAm hydrogel that has absorbed the reactant and seal it in a plastic sample bag. The sample bag is placed under an ultraviolet lamp with a wavelength of 365nm and a power of 300W under 30cm light for 5 hours to obtain the macromolecular electrolyte polymethyl Acrylic acid (PMAA) modified PAAm hydrogel, the hydrogel was soaked in deionized water for 3 days to achieve swelling equilibrium, and the water was changed twice a day to remove impurities such as unreacted monomers and initiators.

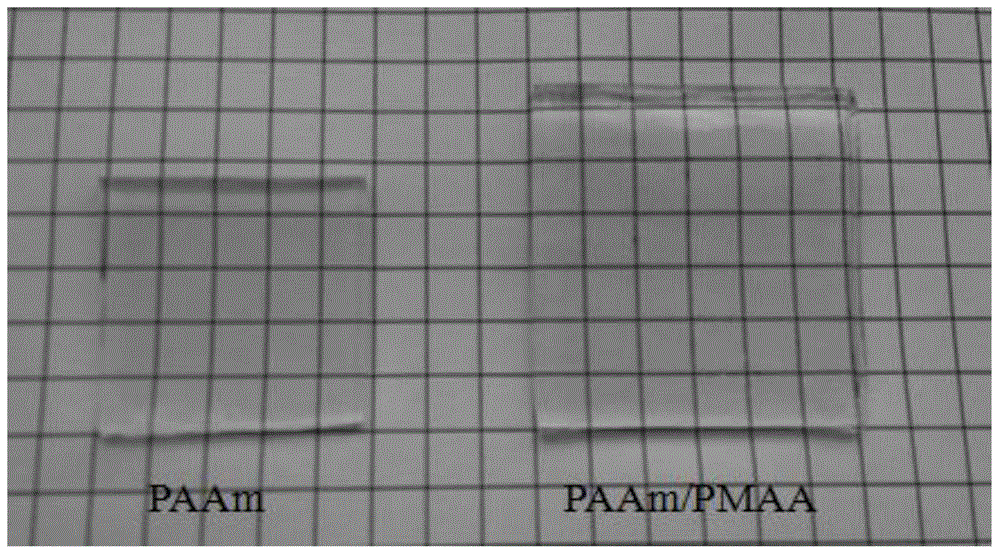

[0048] Experimentally measured: the swelling degree is 42.85, and the water absorption rate is 97.71wt%.

Embodiment 2

[0050] Step 1: soak the neutral PAAm hydrogel of the sample of Comparative Example 1 in a mixed solution of 0.5mol / L MAA and 0.002mol / L KA, and soak in the dark for 2 days;

[0051] Step 2: Take out the neutral PAAm hydrogel that has absorbed the reactant and seal it in a plastic sample bag. The sample bag is placed under an ultraviolet lamp with a wavelength of 365nm and a power of 300W and irradiated at 30cm for 5 hours to obtain a macromolecular electrolyte PMAA modification. For PAAm hydrogel, the hydrogel is soaked in deionized water for 3 days to achieve swelling equilibrium, and the water is changed twice a day to remove impurities such as unreacted monomers and initiators.

[0052] Experimentally measured: the degree of swelling is 54.29, and the water absorption rate is 98.19wt%.

Embodiment 3

[0054] Step 1: soak the neutral PAAm hydrogel of the sample of Comparative Example 1 in a mixed solution of 0.7mol / L MAA and 0.003mol / L KA, and soak in the dark for 3 days;

[0055] Step 2: Take out the neutral PAAm hydrogel that has absorbed the reactant and seal it in a plastic sample bag. The sample bag is placed under a UV lamp with a wavelength of 365nm and a power of 300W under 10cm light for 3 hours to obtain a macromolecular electrolyte PMAA modification For PAAm hydrogel, the hydrogel is soaked in deionized water for 3 days to achieve swelling equilibrium, and the water is changed twice a day to remove impurities such as unreacted monomers and initiators.

[0056] Experimentally measured: the swelling degree is 55.15, and the water absorption rate is 98.22wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com