Double-component composite elastic fiber

An elastic fiber, two-component technology, applied in the direction of fiber processing, filament/thread forming, conjugated synthetic polymer artificial filament, etc., can solve the problem that the number of spring crimps is small, the elastic performance cannot fully meet the requirements, Problems such as large crimping radius, to achieve the effect of small crimping radius, good elasticity, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

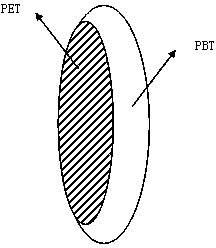

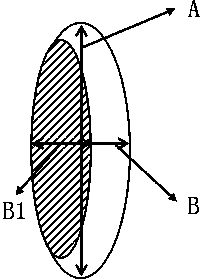

Method used

Image

Examples

Embodiment 1

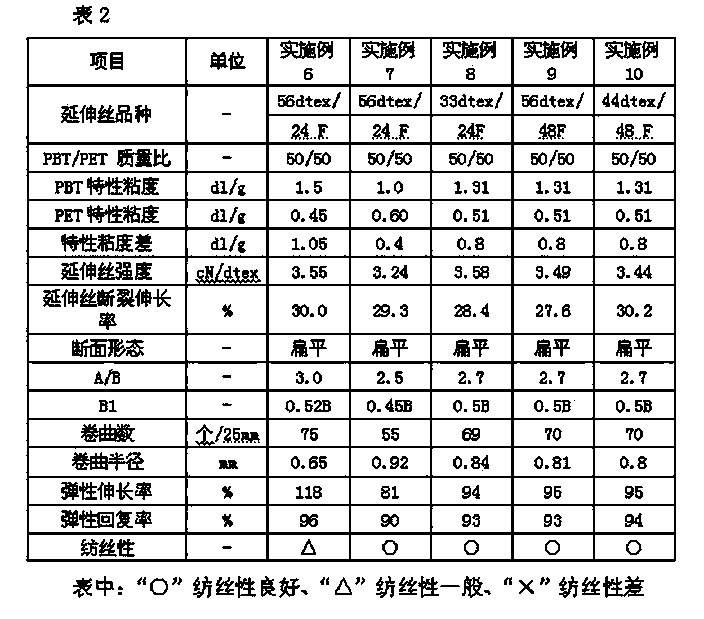

[0050] The two-component elastic fiber was prepared by melting method. The PBT with an intrinsic viscosity of 1.31dl / g and the poly-PET with an intrinsic viscosity of 0.51dl / g were selected for composite spinning, and their intrinsic viscosity difference was 0.80dl / g. Dry them separately so that the water content is less than 100ppm, and put the dried PBT and PET into No. 1 / No. 2 spinning box at a weight ratio of 50:50. Set the spinning temperature, the screw temperature of No. 1 extruder is 265°C; the screw temperature of No. 2 spinning machine is 285°C; the temperature of No. 1 spinning box is 260°C; the temperature of No. 2 spinning box is 280°C. Use side-by-side spinnerets to spin out, adopt a two-step spinning process, and wind up under the condition of 2700m / min at a speed to obtain pre-oriented filaments with good spinnability; and prepare the pre-oriented filaments The wire is stretched and processed on the drafting machine, the processing speed is 700m / min, the temper...

Embodiment 2

[0053] Except that the composite ratio of PBT and PET was changed to 60:40, other spinning processes and conditions were the same as in Example 1. The specific performance parameter data are shown in Table 1.

Embodiment 3

[0055] Except that the composite ratio of PBT and PET was changed to 70:30, other spinning processes and conditions were the same as in Example 1. The specific performance parameter data are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com