A spiral flow anti-sedimentation inverted U-shaped tube

A U-shaped tube and spiral flow technology, which is applied in the field of spiral flow anti-deposition inverted U-shaped tubes, can solve the problems of nuclear power plant economical decline, safety and reliability reduction, etc., to increase economical efficiency and safety, and simple structure , The effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

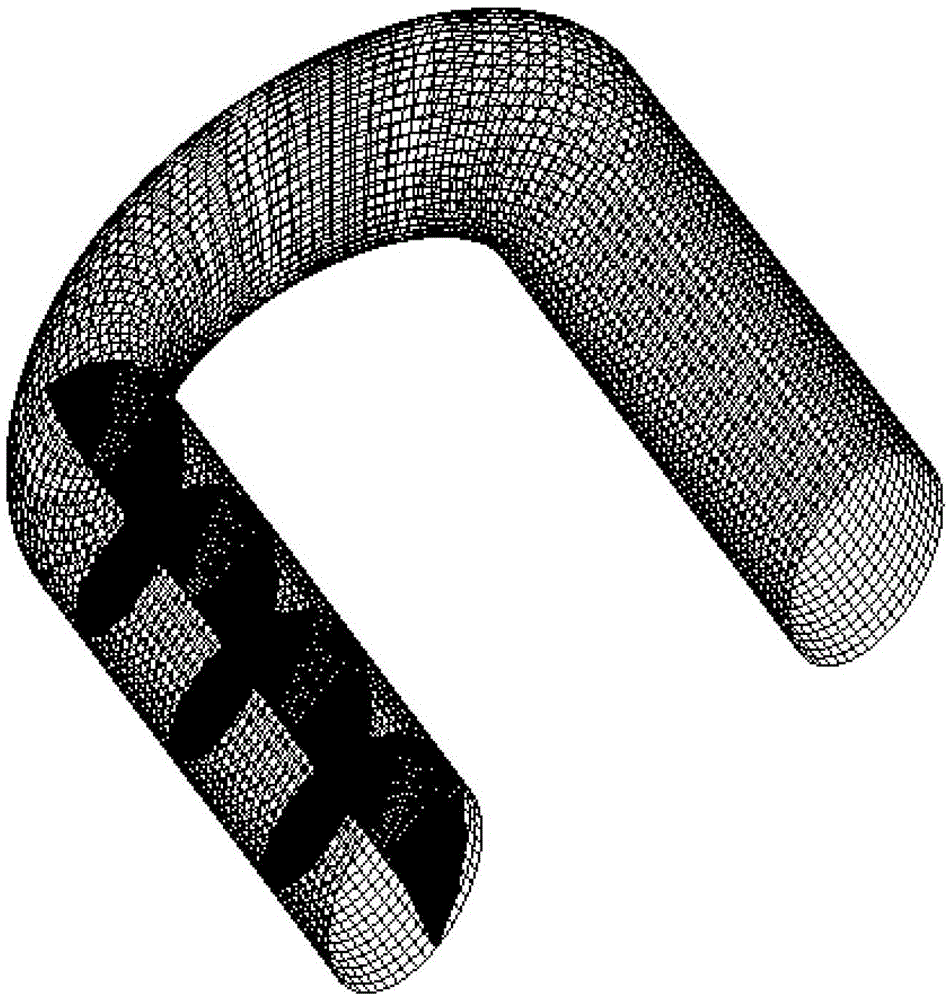

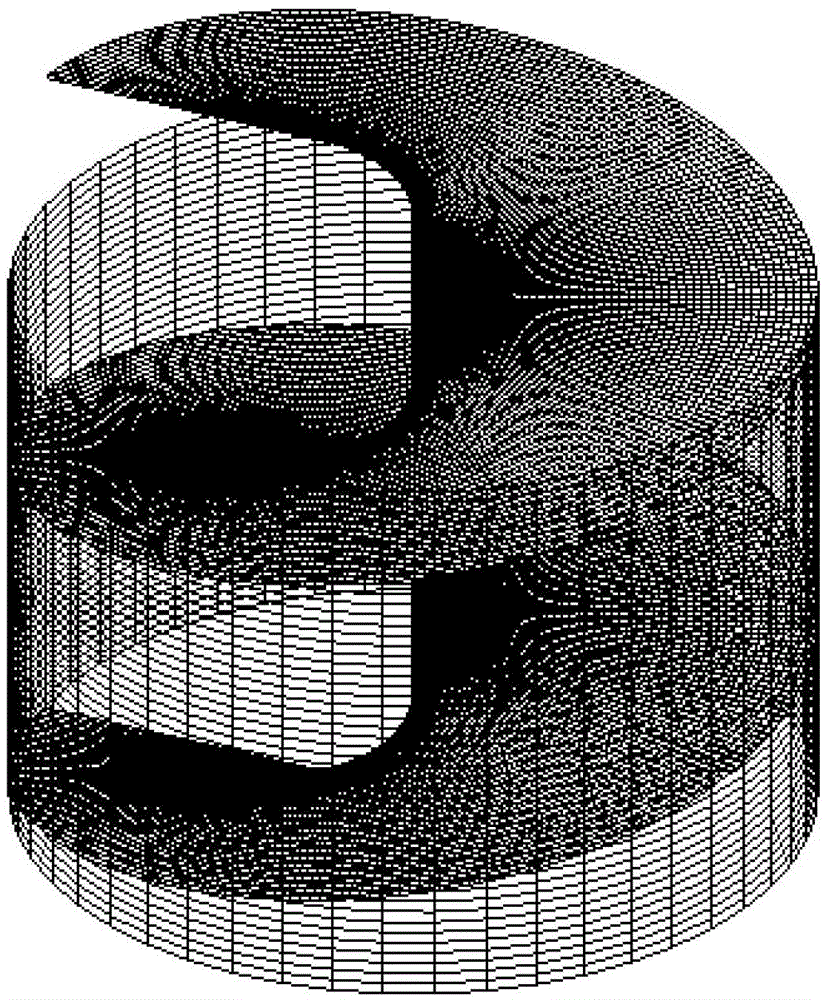

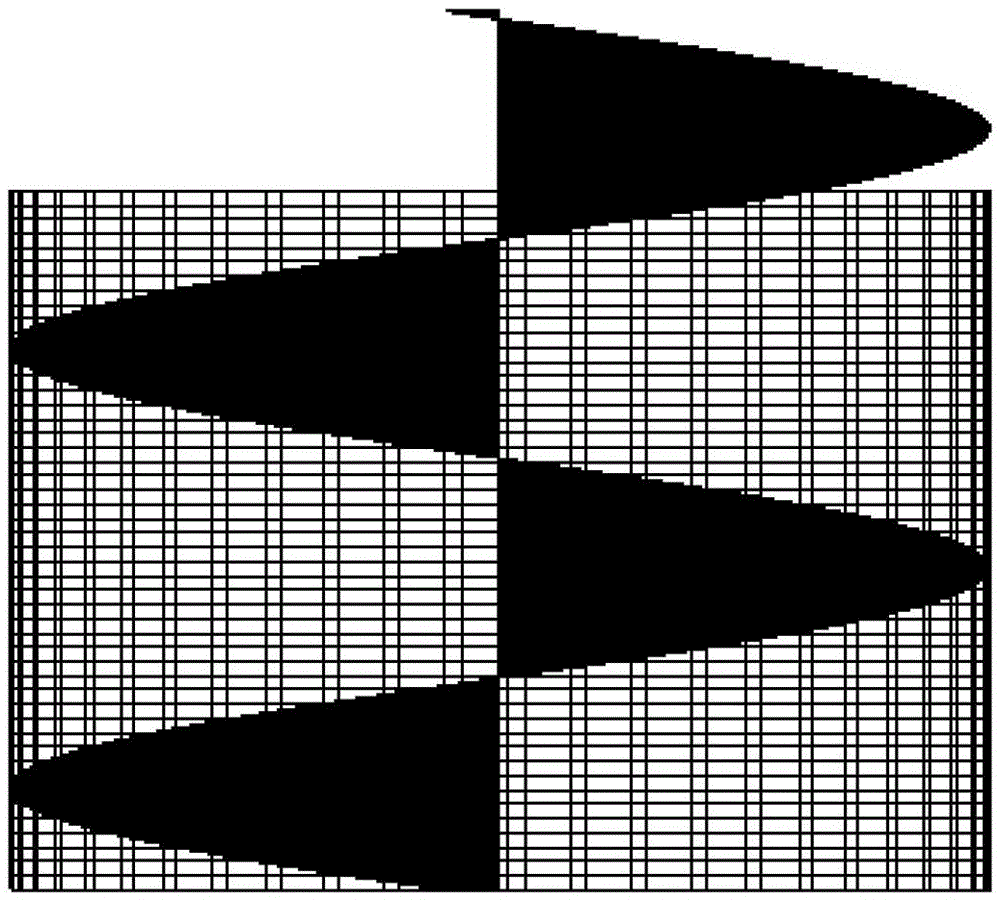

[0047] Such as Figure 1-3 As shown, the spiral flow anti-deposition inverted U-shaped tube used in the production of steam generators, in which the tube wall and spiral baffles are made of inconel690 alloy, the tube wall thickness is 1.5mm, the outer diameter of the inverted U-shaped tube is 20mm, and the spiral baffle The helical surface of the plate is an Archimedes positive helical surface, the thickness is 1.2mm, and the helix angle is 35°. The radial dimension of the helical baffle is the same as the inner diameter of the inverted U-shaped tube. connect.

[0048] Compared with the U-shaped tube without spiral baffles, the anti-deposition effect is increased by 10%, and the heat transfer effect is increased by 10%.

Embodiment 2

[0050] The helical flow anti-deposition inverted U-shaped tube for steam generators similar to Example 1 was produced, wherein the tube wall thickness was 1 mm, the outer diameter of the inverted U-shaped tube was 17 mm, the thickness of the spiral baffle was 1 mm, and the helix angle was 50°.

[0051] Compared with the U-shaped tube without spiral baffles, the anti-deposition effect is increased by 15%, and the heat transfer effect is increased by 15%.

Embodiment 3

[0053] The steam generator similar to Example 1 is produced with a spiral flow type anti-deposition inverted U-shaped tube, wherein the tube wall thickness is 1.5mm, the outer diameter of the inverted U-shaped tube is 20mm, the thickness of the spiral baffle plate is 1.5mm, and the helix angle is 70° .

[0054] Compared with the U-shaped tube without spiral baffles, the anti-deposition effect is increased by 15%, and the heat transfer effect is increased by 17%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com