Method for measuring chitosan oligosaccharide content in specific polymerization degree range

A specific degree of polymerization, chitosan oligosaccharide technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of difficulties in practical application of the method, difficulty in obtaining standard products, etc., and achieve simple operation, few analysis steps, and operability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Determination of the content of oligosaccharides with a degree of polymerization of 2-10 in the chitosan oligosaccharide sample:

[0024] Take by weighing 4 mg of dextran standard substances with molecular weights of 180, 1000, 2500, 5000, 7100, and 12000 respectively, and dissolve them in 1 ml of acetic acid-sodium acetate buffer solution (the concentration of acetic acid in the buffer solution is 0.2mol / L, and the concentration of sodium acetate is 0.1mol / L), adopt high performance gel exclusion chromatography to measure respectively the chromatographic retention time of each dextran standard substance, and the chromatographic condition is:

[0025] Column: TSK G3000-PW XL (250×4.6mm)

[0026] Mobile phase: 0.2M acetic acid / 0.1M sodium acetate buffer

[0027] Flow rate: 0.8mL / min.

[0028] Detector: differential detector.

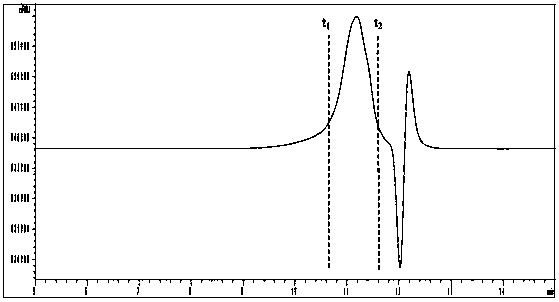

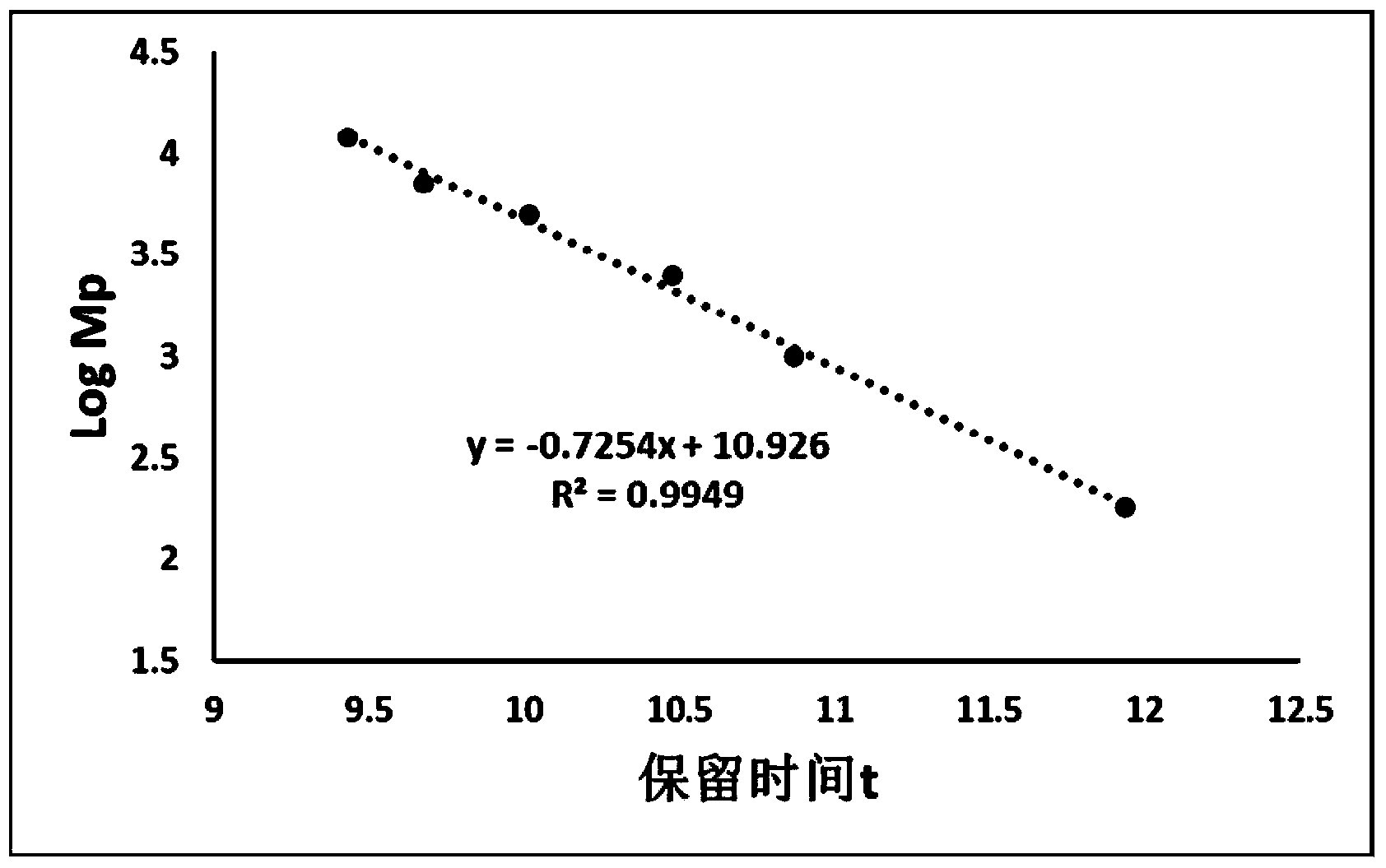

[0029] The chromatographic retention times of dextran standard products with corresponding molecular weights of 180, 1000, 2500, 5000, 7100 a...

Embodiment 2

[0033] Determination of the content of oligosaccharides with a degree of polymerization of 3-8 in chitosan oligosaccharide samples

[0034] Take by weighing 4 mg of dextran standard substances with molecular weights of 180, 1000, 2500, 5000, 7100, and 12000 respectively and dissolve them in 1 ml of acetic acid-sodium acetate buffer solution (the concentration of acetic acid in the buffer solution is 0.2 mol / L, and the concentration of sodium acetate is 0.1 mol / L). In L), adopt high performance gel exclusion chromatography to measure respectively each dextran standard substance chromatographic retention time, chromatographic condition is:

[0035] Column: TSK G3000-PW XL (250×4.6mm)

[0036] Mobile phase: 0.2M acetic acid / 0.1M sodium acetate buffer

[0037] Flow rate: 0.8mL / min.

[0038] Detector: differential detector.

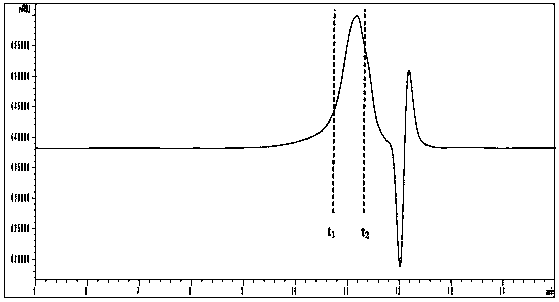

[0039]The chromatographic retention times of dextran standard products with corresponding molecular weights of 180, 1000, 2500, 5000, 7100 and 12000 obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com