Grease composition

A technology of lubricating grease composition and compound, which is applied in the direction of lubricating composition, base material, thickener, etc., can solve the problems of reducing the oil film formation energy of lubricating parts, poor lubrication, etc., and achieve excellent long-term reliability, lubricity and friction good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

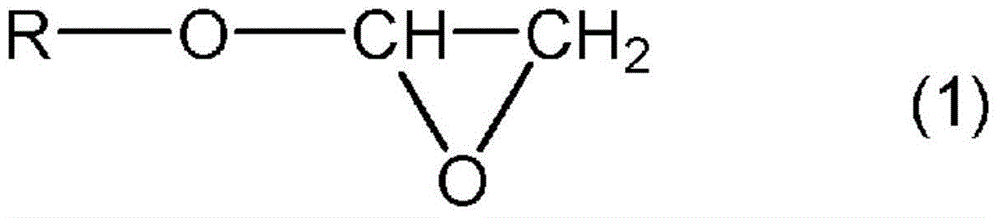

Method used

Image

Examples

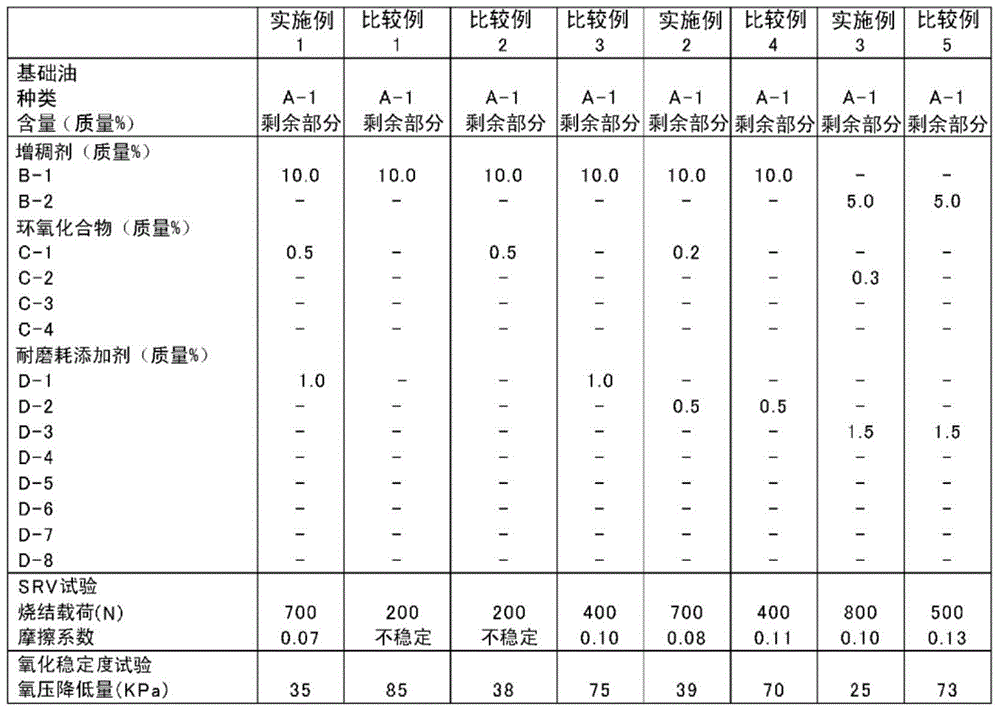

Embodiment 1~28、 comparative example 1~17

[0103] In Examples 1 to 28 and Comparative Examples 1 to 17, grease compositions having the compositions shown in Tables 1 to 6 were prepared using the base oils, thickeners, and additives shown below, respectively.

[0104] (A) base oil

[0105] (A-1) Mineral oil: Paraffin-based refined mineral oil (kinematic viscosity at 40°C: 93.3mm 2 / s, viscosity index 95, pour point -15°C, flash point 260°C)

[0106] (A-2) Polyol ester (POE): The ester formed by the mixed acid of 2-ethylhexanoic acid and 3,5,5-trimethylhexanoic acid in a mass ratio of 5:5 and pentaerythritol (at 40°C The kinematic viscosity is 66.7mm 2 / s, viscosity index 92, pour point -40°C, flash point 248°C)

[0107] (A-3) Polyalkylene glycol (PAG): polyoxypropylene capped with methyl groups at both ends (weight average molecular weight 1000, kinematic viscosity at 40°C 46.0mm 2 / s, viscosity index 190, pour point -45°C, flash point 218°C)

[0108] (A-4) Poly-α-olefin (PAO): a polymer of 1-dodecene (kinematic vi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com