Formula and preparation method of pure natural purple sweet potato mixing powder

A purple sweet potato and brewing powder technology, which is applied in the formula and production field of pure natural instant purple sweet potato brewing powder, can solve the problems of lack of purple sweet potato brewing formula powder, etc., and achieve good flavor, rich nutrition, and enhanced paste effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

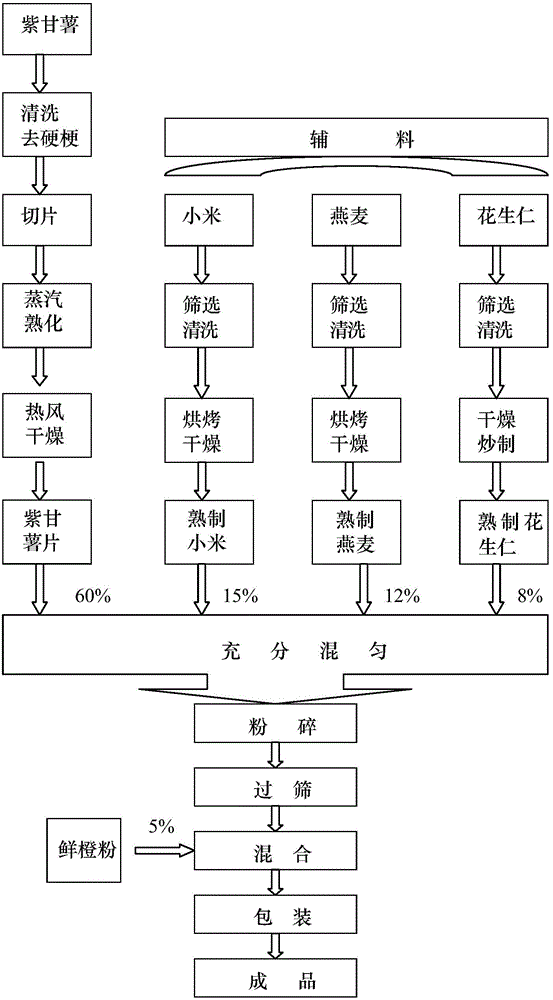

[0019] Example 1: Apply the method provided by the invention to prepare pure natural purple sweet potato powder, formula purple sweet potato slices 60%, millet 15%, oat 12%, peanut kernels 8%, fresh orange powder 5%, combined figure 1 ,Specific steps are as follows:

[0020] The first step, the aging and drying of raw materials:

[0021] (1.1) After cleaning the purple sweet potato, remove the hard stalks at both ends, cut into thin slices of 0.2-0.3 cm; steam ripening in an atmospheric steamer, time when the water boils, and ripen for 4 minutes; the ripened potato chips After cooling with cold air, dry with hot air at 60-80°C until constant weight, and store in a sealed container;

[0022] (1.2) Cleaning and frying of millet: After the millet is sieved by a plane vibrating sieve, it is cleaned by spraying. The cleaned millet is put into a dense gauze bag, and the gauze bag is put into a centrifuge for dehydration. The final millet is placed in a 105°C constant temperature...

Embodiment 2

[0031] Example 2: Apply the method provided by the invention to prepare pure natural purple sweet potato brewing powder. In the second step, choose the raw material formula purple sweet potato slices 55%, millet 16%, oat 14%, peanut kernels 10%, fresh orange powder 5%, and the rest With embodiment 1.

Embodiment 3

[0032] Example 3: Apply the method provided by the invention to prepare pure natural purple sweet potato powder. In the second step, choose the raw material formula purple sweet potato slices 65%, millet 12%, oat 10%, peanut kernels 8%, fresh orange powder 5%, and the rest With embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com