Anti-carbon synthesis gas methanation catalyst, preparation method and application thereof

A catalyst and gas methane technology, which is applied in the field of anti-coking catalysts and their preparation, can solve the problems of difficult to achieve homogenization of raw materials, heterogeneous phase of magnesium-aluminum spinel materials, affecting the anti-coking ability of catalysts, etc. The effect of the bed reaction temperature, the improvement of the anti-coking ability, and the increase of the number of nickel active centers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

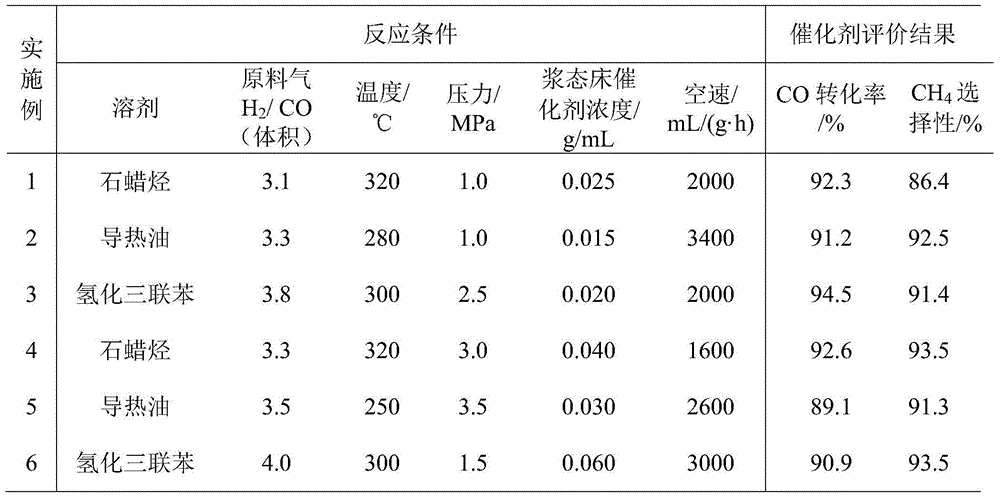

Examples

Embodiment 1

[0028] (1) Carrier pretreatment: 10g 80-100 mesh γ-Al 2 o 3 The carrier is calcined at 450°C for 2h;

[0029] (2) Impregnation and deposition: weigh 16.30g NiCl 2 ·6H 2 O and 0.624g La(NO 3 ) 3 ·6H 2 O dissolved in 15ml H 2 O, equal volume impregnation of pretreated γ-Al 2 o 3 , soaked at 30°C for 12h; then add 25wt% ammonia solution to control NH 3 ·H 2 O / Ni 2+ The molar ratio is 4:1, the deposition is 3h;

[0030] (3) Evaporation and drying: Evaporate the impregnated sample in (2) to a pH of 8.5 in a 90°C water bath and dry it at 100°C for 9 hours;

[0031] (4) Roasting: After grinding the dried carrier in (3), calcined at 550°C for 3h to obtain NiO / γ-Al 2 o 3 Precursor;

[0032] (5) Hydrogen reduction: NiO / γ-Al 2 o 3 The precursor is composed of 5% H by volume 2 with 95%N 2 The catalyst was obtained after reduction at 450°C for 9 hours in a mixed atmosphere. The composition of the product catalyst was Ni 37.6%, La 1.8%, γ-Al 2 o 3 60.6%.

[0033]See At...

Embodiment 2

[0036] (1) Carrier pretreatment: 10g 120-140 mesh γ-Al 2 o 3 The carrier is calcined at 550°C for 2h;

[0037] (2) Impregnation and deposition: weigh 14.17g NiCl 2 ·6H 2 O and 0.85 g MoCl 5 Dissolve in 15ml H 2 O, equal volume impregnation of pretreated γ-Al 2 o 3 , impregnated at 50°C for 6h; then add 25wt% ammonia solution to control NH 3 ·H 2 O / Ni 2+ The molar ratio is 8:1, and the deposition is 3h;

[0038] (3) Evaporation and drying: Evaporate the impregnated sample in (2) to a pH of 8.3 in a 70°C water bath, and dry it at 110°C for 4 hours;

[0039] (4) Roasting: After grinding the dried carrier in (3), calcined at 500°C for 2h to obtain NiO / γ-Al 2 o 3 Precursor;

[0040] (5) Hydrogen reduction: NiO / γ-Al 2 o 3 The precursor is 15% H in volume composition 2 with 85% N 2 Ni / γ-Al was obtained after reduction at 400℃ for 6h in a mixed atmosphere 2 o 3 Catalyst. The composition of the product catalyst is Ni32.8%, Mo2.1%, γ-Al 2 o 3 65.1%

[0041] See Att...

Embodiment 3

[0044] (1) Carrier pretreatment: 10g 140-160 mesh γ-Al 2 o 3 The carrier is calcined at 350°C for 3h;

[0045] (2) Impregnation and deposition: Weigh 12.71g Ni(CH 3 COO) 2 4H 2 O and 1.42 g MoCl 5 dissolved in 15mlH 2 O, equal volume impregnation of pretreated γ-Al 2 o 3 , impregnated at 70°C for 4h; then add 25wt% ammonia solution to control NH 3 ·H 2 O / Ni 2+ The molar ratio is 7:1, the deposition is 3h;

[0046] (3) Evaporation and drying: Evaporate the impregnated sample in (2) to a pH of 8.5 in a 70°C water bath, and dry it at 100°C for 6 hours;

[0047] (4) Calcination: After grinding the dried carrier in (3), calcinate at 550°C for 1 hour to obtain NiO / γ-Al 2 o 3 Precursor;

[0048] (5) Hydrogen reduction: NiO / γ-Al 2 o 3 The precursor is 20% H in volume composition 2 with 80%N 2 Ni / γ-Al was obtained after reduction at 550℃ for 5h in a mixed atmosphere 2 o 3 Catalyst. The composition of the product catalyst is Ni 28.2%, Mo 4.3% γ-Al 2 o 3 67.5%.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com