A kind of synthesis gas methanation catalyst anti-carbon deposition and its preparation method and application

A technology of catalyst and gas methane, which is applied in the field of anti-carbon deposition catalyst and its preparation, can solve the problems of affecting the anti-carbon deposition ability of the catalyst, the inhomogeneity of magnesium aluminum spinel materials, and the difficulty of homogenizing raw materials, etc., to achieve weakening Coke phenomenon, reduce the bed reaction temperature, improve the effect of anti-coke ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

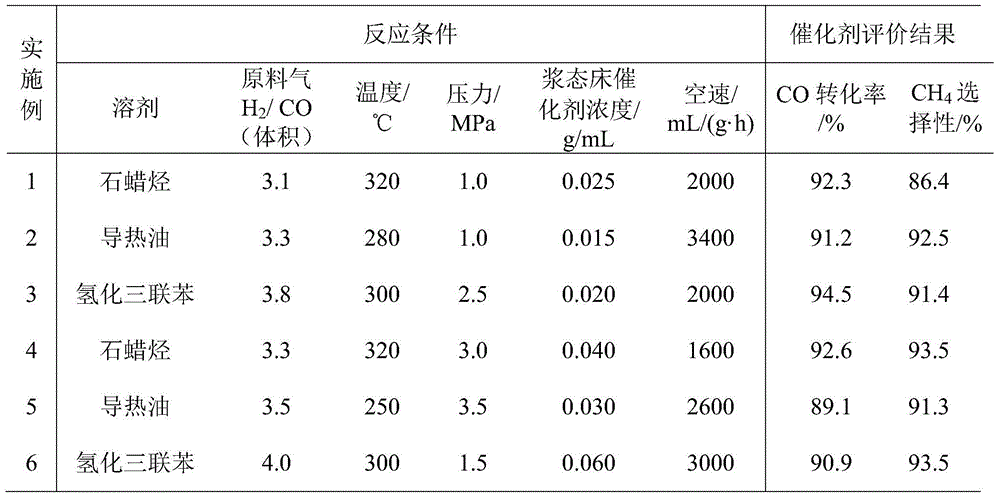

Examples

Embodiment 1

[0029] (1) Carrier pretreatment: 10g 80-100 mesh γ-Al 2 o 3 The carrier is calcined at 450°C for 2h;

[0030] (2) Impregnation and deposition: weigh 16.30g NiCl 2 ·6H 2 O and 0.624g La(NO 3 ) 3 ·6H 2 O dissolved in 15ml H 2 O, equal volume impregnation of pretreated γ-Al 2 o 3 , soaked at 30°C for 12h; then add 25wt% ammonia solution to control NH 3 ·H 2 O / Ni 2+ The molar ratio is 4:1, the deposition is 3h;

[0031] (3) Evaporation and drying: Evaporate the impregnated sample in (2) to a pH of 8.5 in a 90°C water bath and dry it at 100°C for 9 hours;

[0032] (4) Roasting: After grinding the dried carrier in (3), calcined at 550°C for 3h to obtain NiO / γ-Al 2 o 3 Precursor;

[0033] (5) Hydrogen reduction: NiO / γ-Al 2 o 3 The precursor is composed of 5% H by volume 2 with 95%N 2 The catalyst was obtained after reduction at 450°C for 9 hours in a mixed atmosphere. The composition of the product catalyst was Ni 37.6%, La 1.8%, γ-Al 2 o 3 60.6%.

[0034] See A...

Embodiment 2

[0037] (1) Carrier pretreatment: 10g 120-140 mesh γ-Al 2 o 3 The carrier is calcined at 550°C for 2h;

[0038] (2) Impregnation and deposition: weigh 14.17g NiCl 2 ·6H 2 O and 0.85 g MoCl 5 Dissolve in 15ml H 2 O, equal volume impregnation of pretreated γ-Al 2 o 3 , impregnated at 50°C for 6h; then add 25wt% ammonia solution to control NH 3 ·H 2 O / Ni 2+ The molar ratio is 8:1, and the deposition is 3h;

[0039] (3) Evaporation and drying: Evaporate the impregnated sample in (2) to a pH of 8.3 in a 70°C water bath, and dry it at 110°C for 4 hours;

[0040] (4) Roasting: After grinding the dried carrier in (3), calcined at 500°C for 2h to obtain NiO / γ-Al 2 o 3 Precursor;

[0041] (5) Hydrogen reduction: NiO / γ-Al 2 o 3 The precursor is 15% H in volume composition 2 with 85%N 2 Ni / γ-Al was obtained after reduction at 400℃ for 6h in a mixed atmosphere 2 o 3 Catalyst. The composition of the product catalyst is Ni32.8%, Mo2.1%, γ-Al 2 o 3 65.1%

[0042] See Atta...

Embodiment 3

[0045] (1) Carrier pretreatment: 10g 140-160 mesh γ-Al 2 o 3 The carrier is calcined at 350°C for 3h;

[0046] (2) Impregnation and deposition: Weigh 12.71g Ni(CH 3 COO) 2 4H 2 O and 1.42 g MoCl 5 dissolved in 15mlH 2 O, equal volume impregnation of pretreated γ-Al 2 o 3 , impregnated at 70°C for 4h; then add 25wt% ammonia solution to control NH 3 ·H 2 O / Ni 2+ The molar ratio is 7:1, the deposition is 3h;

[0047] (3) Evaporation and drying: Evaporate the impregnated sample in (2) to a pH of 8.5 in a 70°C water bath, and dry it at 100°C for 6 hours;

[0048] (4) Calcination: After grinding the dried carrier in (3), calcinate at 550°C for 1 hour to obtain NiO / γ-Al 2 o 3 Precursor;

[0049] (5) Hydrogen reduction: NiO / γ-Al 2 o 3 The precursor is 20% H in volume composition 2 with 80%N 2 Ni / γ-Al was obtained after reduction at 550℃ for 5h in a mixed atmosphere 2 o 3 Catalyst. The composition of the product catalyst is Ni 28.2%, Mo 4.3% γ-Al 2 o 3 67.5%.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com