Transparent glass ceramic having double-frequency light absorption and conversion capability and preparation method for transparent glass ceramic

A technology for preparing transparent glass and ceramics, which is applied in the synthesis of transparent glass ceramics, dual-frequency light conversion performance and related transparent glass ceramics. It can solve the problem that there is no way to convert infrared light and ultraviolet light to visible light at the same time, and achieve good thermal stability. and chemical stability, the effect of the preparation method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

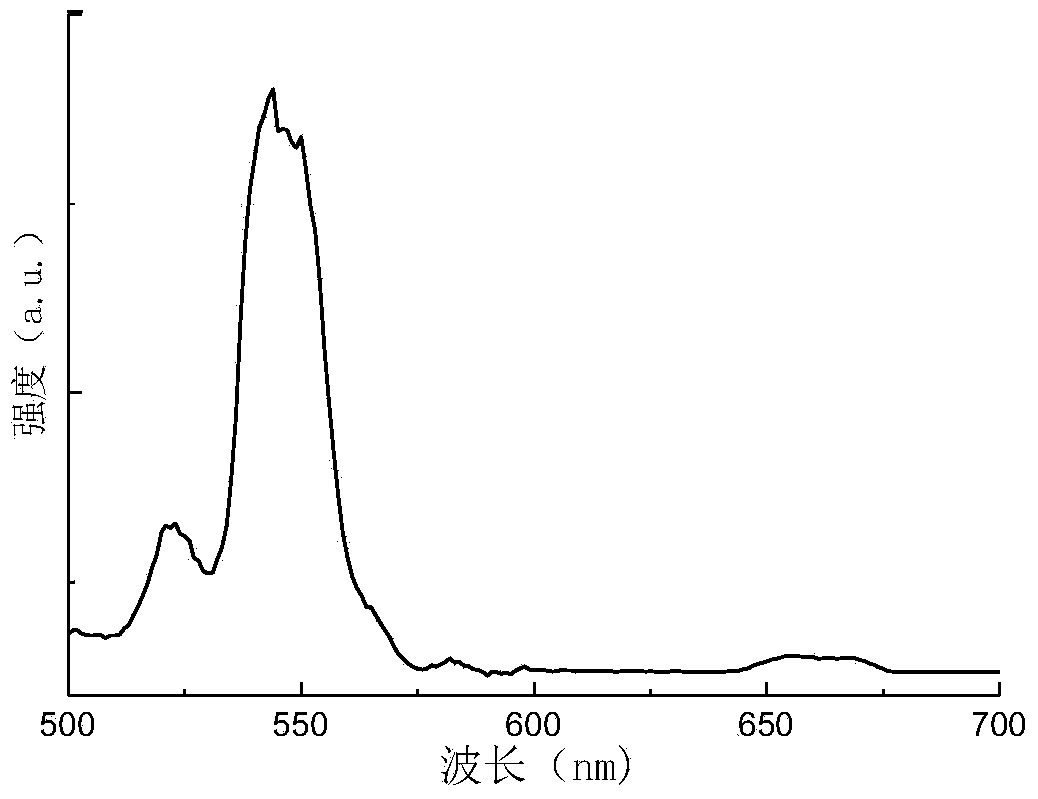

[0028] Matrix raw material selection Al 2 o 3 , Na 2 CO 3 , SiO 2 , CaCO 3 , the crystallite nucleation material is chosen as YF 3 and NaF, the doped luminescent center ion is selected as ErF 3 . Raw material ratio is 15% Al 2 o 3 , 10% Na 2 CO 3 , 45% SiO 2 , 4% CaCO 3 , (8%-x)YF 3 and 18% NaF, xErF 3 , x=1%, 1.5%. Weigh the above powder raw materials, mix them in an agate mortar, add 2 ml of alcohol to grind, then place them in a corundum crucible, heat them in an electric furnace to 1500°C and keep them warm for 1 hour to fully melt them. Afterwards, the glass solution was taken out and quickly poured into a copper mold to form a bulk precursor glass. The obtained bulk precursor glass was placed in an electric furnace for annealing at 660°C for 1 hour to eliminate internal stress and promote microcrystalline crystallization. Sample is through surface polishing, and obtains green light and red light emission under 378nm and 980nm excitation, and the emission ...

Embodiment 5-8

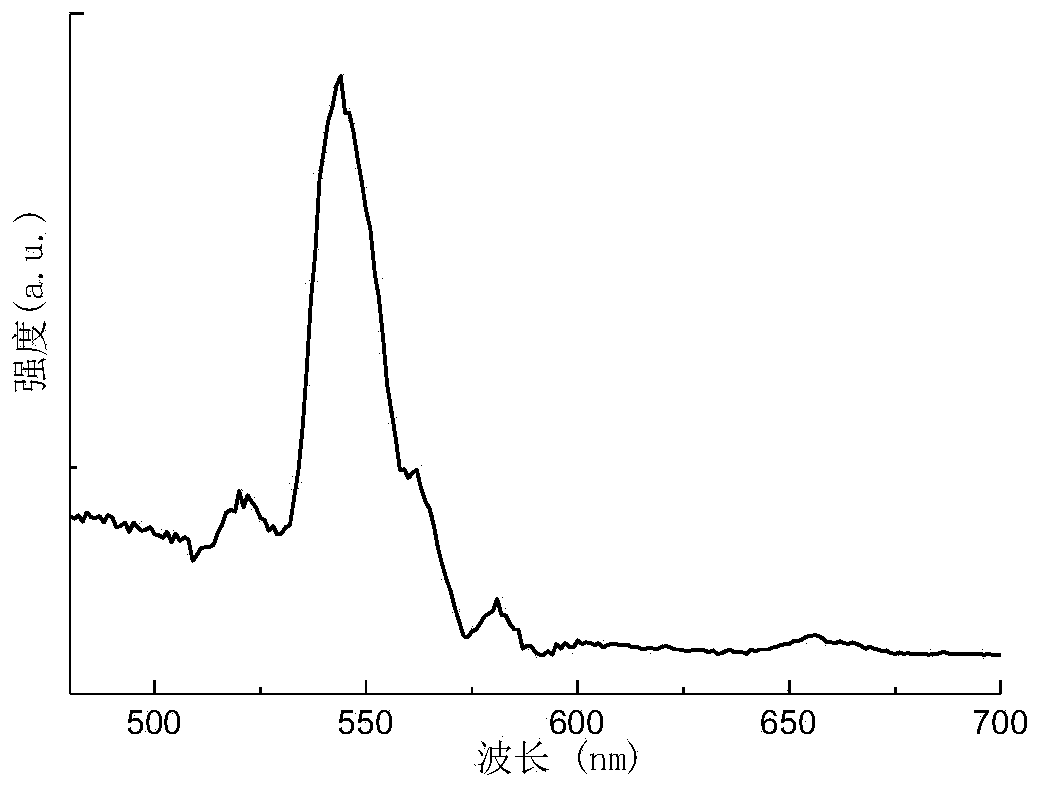

[0033] Matrix raw material selection Al 2 o 3 , Na 2 CO 3 , SiO 2 , CaCO 3 , the crystallite nucleation material is chosen as LuF 3 and NaF, the doped luminescent center ion is selected as ErF 3 . Raw material ratio is 15% Al 2 o 3 , 10% Na 2 CO 3 , 45% SiO 2 , 4% CaCO 3 , (8%-x)LuF 3 and 18% NaF, xErF 3 , x=1%, 1.5%. Weigh the above powder raw materials, mix them in an agate mortar, add 2 ml of alcohol to grind, then place them in a corundum crucible, heat them in an electric furnace to 1500°C and keep them warm for 1 hour to fully melt them. Afterwards, the glass solution was taken out and quickly poured into a copper mold to form a bulk precursor glass. The obtained bulk precursor glass was placed in an electric furnace at 650°C for 2 hours to eliminate internal stress and promote microcrystalline crystallization. Sample is through surface polishing, obtains green light and red light emission under 378nm and 980nm excitation, and the emission spectrum of emb...

Embodiment 9-12

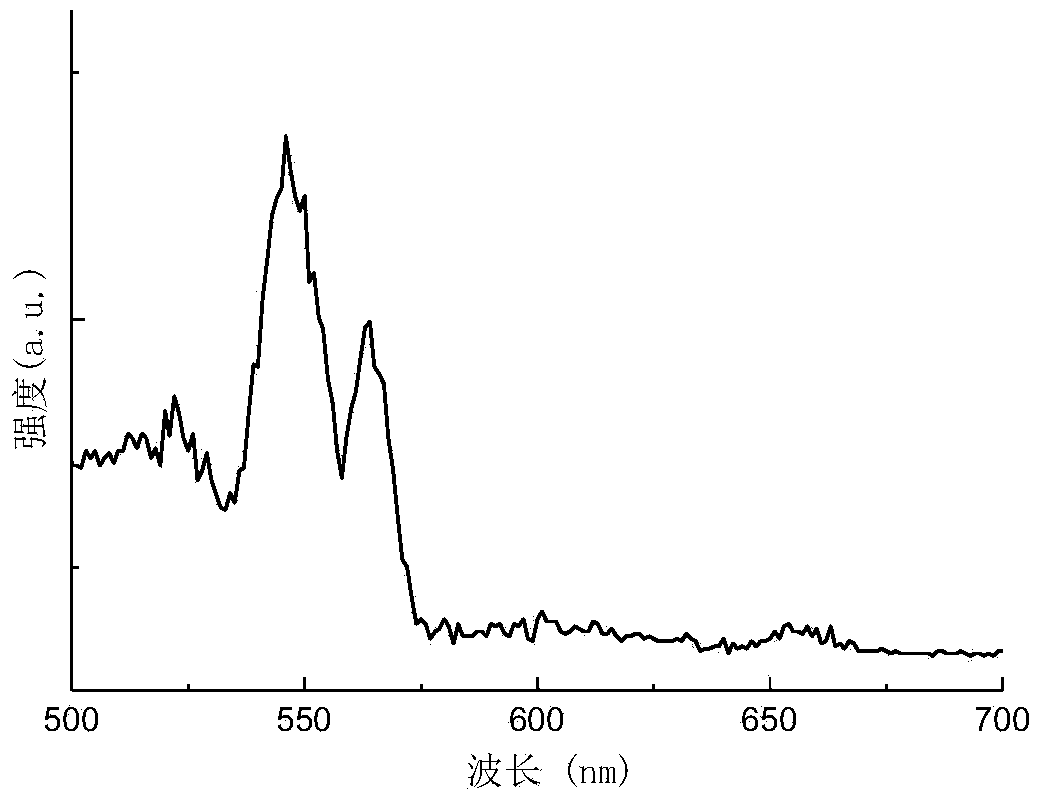

[0037] Matrix raw material selection Al 2 o 3 , Na 2 CO 3 , SiO 2 , the crystallite nucleation material is chosen as LaF 3 , the doped luminescent center ion is selected as ErF 3 . Raw material ratio is 25% Al 2 o 3 , 19% Na 2 CO 3 , 41% SiO 2 , (15%-x)LaF 3 , xErF 3 , x=1%, 1.5%. Weigh the above powder raw materials, mix them in an agate mortar, add 2 ml of alcohol to grind, then place them in a corundum crucible, heat them in an electric furnace to 1500°C and keep them warm for 1 hour to fully melt them. Afterwards, the glass solution was taken out and quickly poured into a copper mold to form a bulk precursor glass. The obtained bulk precursor glass was placed in an electric furnace at 680°C for 2 hours to eliminate internal stress and promote microcrystalline crystallization. Sample is through surface polishing, obtains green light and red light emission under 378nm and 980nm excitation, and the emission spectrum of embodiment 9 is as follows image 3 shown....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com