A kind of nylon 6 resin for food packaging material, its preparation method and its application

A food packaging and nylon technology, applied in the field of nylon 6 resin, can solve the problems of high caprolactam content, high price, low viscosity and difficult film formation, etc., and achieve the effects of improving polymerization efficiency, reducing product toxicity, and high repolymerization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

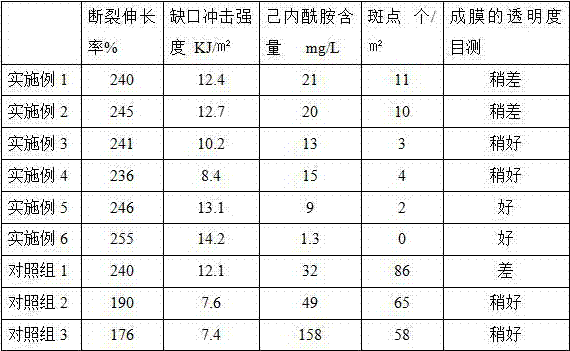

Examples

Embodiment 1-6

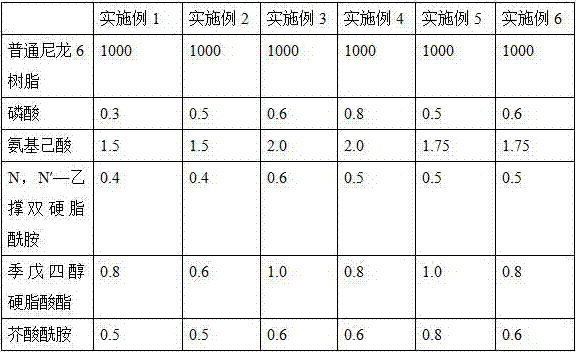

[0031] Table 1 Example 1-6 components and parts by weight

[0032]

[0033] The ordinary nylon 6 resin is selected from the Zhuangyuan brand nylon 6 resin produced by Sinopec Shijiazhuang Refining and Chemical Branch, with a relative viscosity of 2.75; 6 aminocaproic acid is produced by Shanghai Jianglai Biotechnology Co., Ltd.; the N, N'-ethylene bismuth Stearamide is N, N'-vinyl bis stearamide, which is a diffusing agent, produced in Malaysia and distributed by Tianjin Huanqi Chemical Co., Ltd.

preparation example 1-6

[0035] Preparation examples 1-6 adopt the raw materials and proportioning of embodiment 1-6 respectively, adopt the following steps to prepare:

[0036] Step ⑴: Mixing and drying, take the raw materials and the proportion, add them to the vacuum drum, use a vacuum pump to evacuate to a pressure of -0.098 ~ 0.1MPa, heat to 110°C, and keep the temperature for 2-3 hours; the main function is to The material is dry to ensure a higher rate of viscosity increase in the next stage.

[0037]Step ⑵: Constant temperature detection, within 4-6 hours, the temperature is raised to 174°C-205°C at a rate of 16°C / hour, and the temperature is kept constant for 6-12 hours. From 3.4 to 3.8, the temperature is lowered to 130°C, and the cooling rate is 11 to 19°C / hour.

[0038] Step ⑶: Vacuumize and fill with nitrogen, start the vacuum pump again to evacuate for 60-70 minutes to extract unpolymerized low-molecular substances, the vacuum degree is -0.095--0.1MPa, fill in nitrogen and cool down to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com