Coated proppant and preparation method thereof

A proppant and film coating technology, which is applied in chemical instruments and methods, earthwork drilling, and fluid extraction, etc., can solve the problems of high construction risk, high density, and low compressive strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

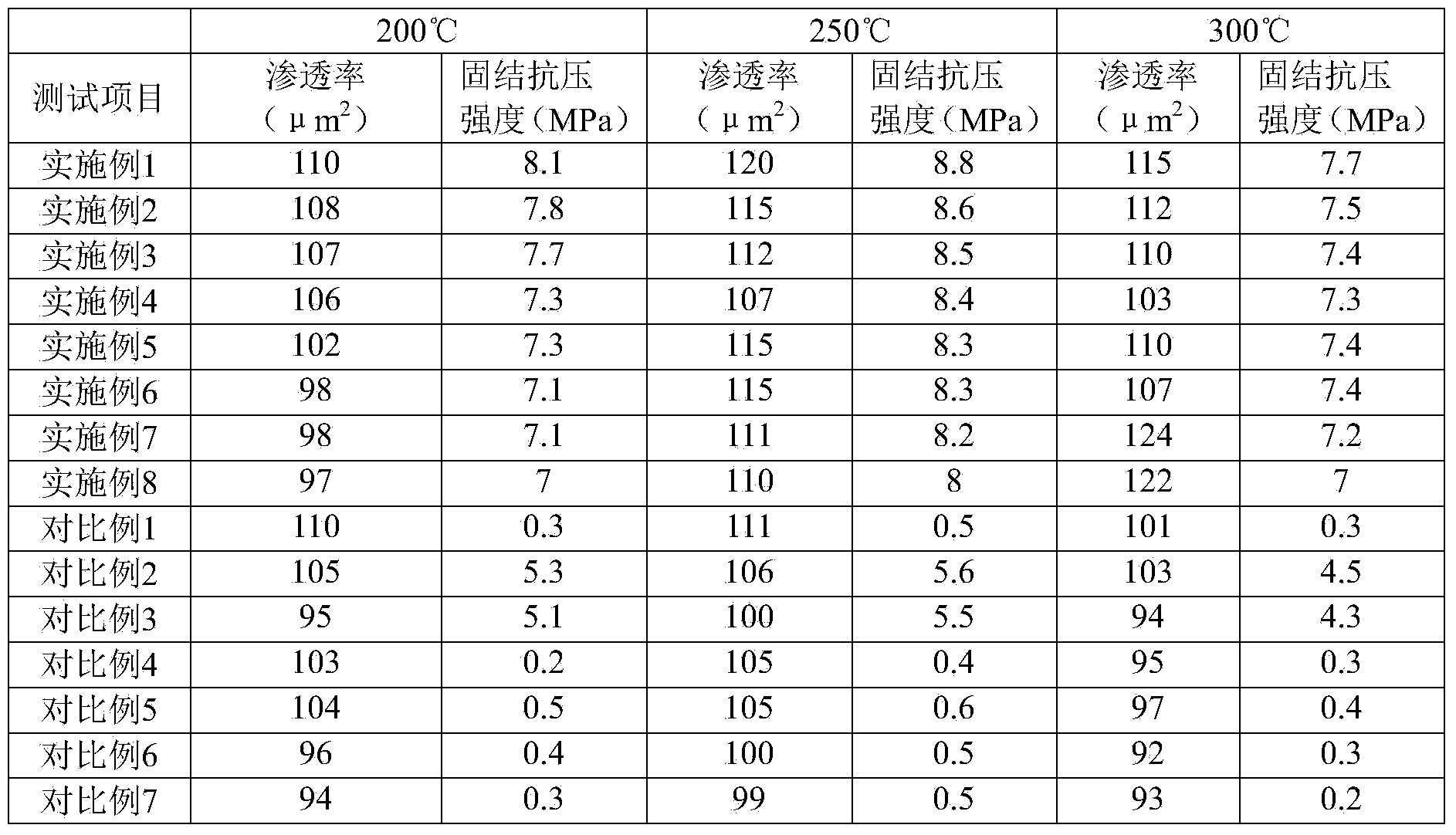

Examples

Embodiment 1

[0023] (1) Heat the quartz sand (particle size: 0.5mm) to 250°C and pour it into the sand mixer; (2) When the temperature of the quartz sand reaches 200°C, add bismuth with an epoxy value of 0.18mol / 100g Phenol A epoxy resin (Langfang Nuoerxin Chemical Co., Ltd., model 603) and o-cresol novolac epoxy resin (Hunan Tuo Suo Technology Co., Ltd., TPCN-703) with an epoxy value of 0.55mol / 100g, stir evenly; (3 ) Add diaminodiphenylmethane (Chengdu Yuanda Chemical Co., Ltd.) to the above mixture, and stir until it is fully solidified; (4) Add phenol-formaldehyde resin with a softening point of 98°C to the result of step (3) (Shijiazhuang Feng United Fine Chemical Co., Ltd.), stir evenly; (5) when the temperature of the quartz sand drops to 95° C., add hexamethylenetetramine (Jinan Shengwang Chemical Co., Ltd.) to the result of step (4), stir until Quartz sand is uniformly dispersed; wherein, relative to 100 parts by weight of quartz sand, the total amount of phenol-formaldehyde resin...

Embodiment 2

[0025](1) Heat the quartz sand (particle size: 0.5mm) to 250°C and pour it into the sand mixer; (2) When the temperature of the quartz sand reaches 200°C, add bismuth with an epoxy value of 0.18mol / 100g Phenol A epoxy resin (Langfang Nuoerxin Chemical Co., Ltd., model 603) and o-cresol novolac epoxy resin (Hunan Tuo Suo Technology Co., Ltd., TPCN-703) with an epoxy value of 0.55mol / 100g, stir evenly; (3 ) Add diaminodiphenylmethane (Chengdu Yuanda Chemical Co., Ltd.) to the above mixture, and stir until fully solidified; (4) Add phenol-formaldehyde resin with a softening point of 90°C to the resultant of step (3) (Shijiazhuang Feng United Fine Chemical Co., Ltd.), stir evenly; (5) when the temperature of the quartz sand drops to 95° C., add hexamethylenetetramine (Jinan Shengwang Chemical Co., Ltd.) to the result of step (4), stir until Quartz sand is uniformly dispersed; wherein, relative to 100 parts by weight of quartz sand, the total amount of phenol-formaldehyde resin and...

Embodiment 3

[0027] (1) Heat the quartz sand (particle size: 0.5mm) to 250°C and pour it into the sand mixer; (2) When the temperature of the quartz sand reaches 200°C, add bismuth with an epoxy value of 0.18mol / 100g Phenol A epoxy resin (Langfang Nuoerxin Chemical Co., Ltd., model 603) and o-cresol novolac epoxy resin (Hunan Tuo Suo Technology Co., Ltd., TPCN-703) with an epoxy value of 0.55mol / 100g, stir evenly; (3 ) Add diaminodiphenylmethane (Chengdu Yuanda Chemical Co., Ltd.) to the above mixture, and stir until fully solidified; (4) Add phenol-formaldehyde resin with a softening point of 110°C to the result of step (3) (Shijiazhuang Feng United Fine Chemical Co., Ltd.), stir evenly; (5) when the temperature of the quartz sand drops to 95° C., add hexamethylenetetramine (Jinan Shengwang Chemical Co., Ltd.) to the result of step (4), stir until Quartz sand is uniformly dispersed; wherein, relative to 100 parts by weight of quartz sand, the total amount of phenol-formaldehyde resin and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com