Production method of high-acid high-ester flavoring liquor

A high-acid high-ester and production method technology, applied in the field of brewing, can solve the problems of increasing manpower and material costs, increasing enterprise operating costs, and consuming large grain resources, so as to save manpower costs, lower production costs, and increase the company's economic benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

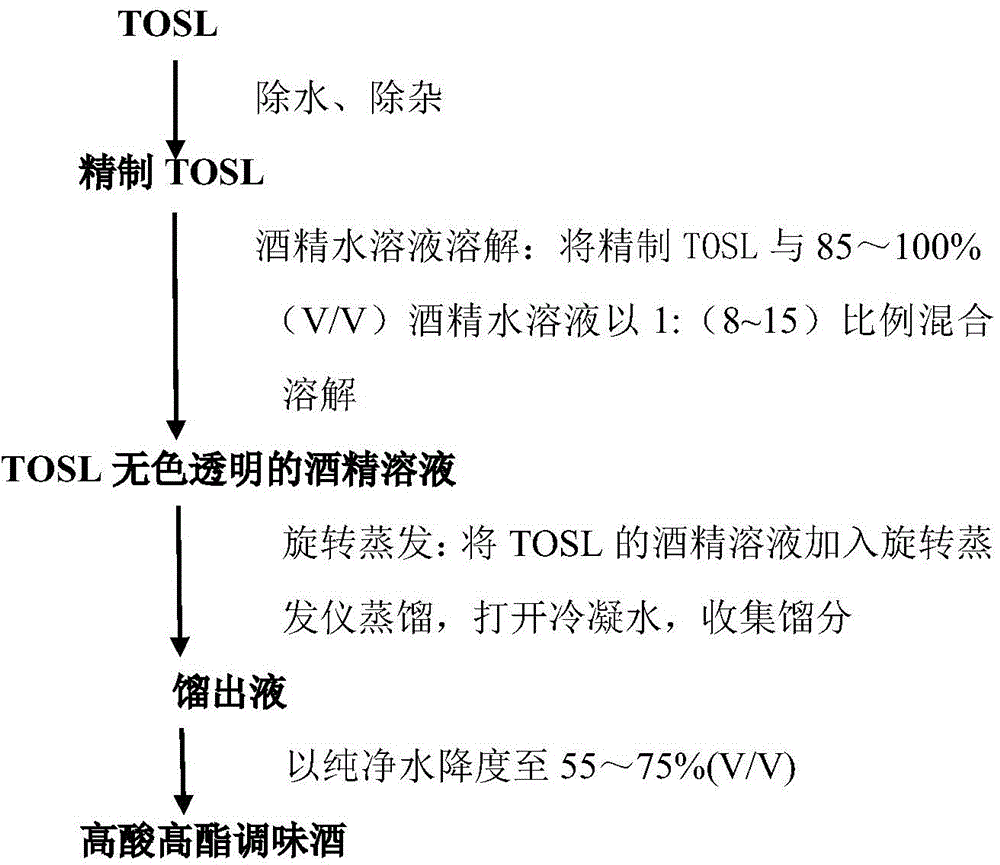

[0024] Embodiment 1 produces high-acid high-ester seasoning wine with Luzhou-flavor liquor tail water oil according to the following steps

[0025] (1) TOSL water removal and impurity removal: First, pour the TOSL collected from the Luzhou-flavor workshop into the oil-water separator, let it stand for 1 hour, then release the tail water of the lower layer, discard it, and take the upper layer of yellow clear oil; The oil is filtered with absorbent cotton cake to remove solid impurities.

[0026] (2) Dissolving in 85% (V / V) alcoholic aqueous solution: Mix and dissolve TOSL, which removes water and solid impurities, and 85% (V / V) alcoholic aqueous solution at a ratio of 1:10 to obtain a colorless and transparent alcoholic solution.

[0027] (3) Rotary evaporation: put the alcohol solution of TOSL into a rotary evaporator for distillation, the oil bath temperature is 95-100°C, the rotation speed is 30-40 rpm, turn on the cooling water, and collect the distillate.

[0028] (4) De...

Embodiment 2

[0029] Embodiment 2 produces high-acid high-ester seasoning wine with Luzhou-flavor type liquor tail water oil according to the following steps

[0030] (1) TOSL water removal and impurity removal: first, pour the TOSL collected from the Luzhou-flavor workshop into the oil-water separator, let it stand for 1.5 hours, then release the tail water of the lower layer, discard it, and take the upper layer of yellow clear oil; The liquid was filtered with diatomaceous earth to remove solid impurities.

[0031] (2) Dissolving in high alcohol solution: mix and dissolve TOSL which removes water and solid impurities and 85-100% (V / V) alcohol aqueous solution at a ratio of 1:10 to obtain a colorless and transparent alcohol solution.

[0032] (3) Rotary evaporation: Add the TOSL alcohol solution to a rotary evaporator for distillation, the oil bath temperature is 100-105°C, the rotation speed is 30-40 rpm, turn on the cooling water, and collect the distillate.

[0033] (4) Alcohol reduct...

Embodiment 3

[0034] Embodiment 3 produces high-acid high-ester seasoning wine with Luzhou-flavor liquor tail water oil according to the following steps

[0035] (1) TOSL water removal and impurity removal: first, pour the TOSL collected from the Luzhou-flavor workshop into the oil-water separator, let it stand for 1 hour, then release the tail water of the lower layer, and take the upper layer of yellow clear oil; Vinylon filter cloth to filter to remove solid impurities.

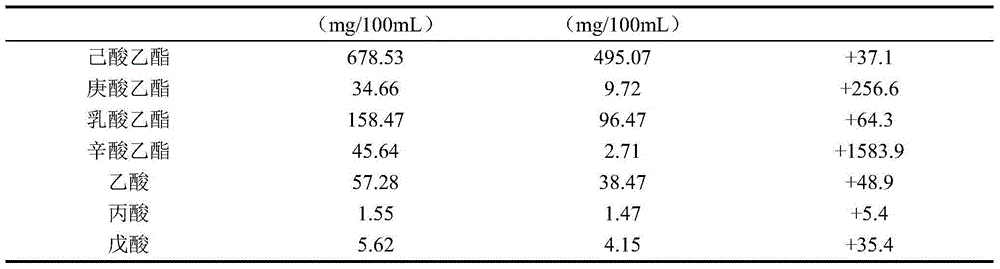

[0036] (2) Edible alcohol dissolution: Mix and dissolve TOSL for removing water and solid impurities and edible grade pure alcohol at a ratio of 1:10 to obtain a colorless and transparent alcohol solution. The TOSL alcohol solution was sampled, and the content of the main aroma and taste substances was detected by gas chromatography.

[0037] (3) Rotary evaporation: Add the TOSL alcohol solution to a rotary evaporator for distillation, the oil bath temperature is 95-105°C, the rotation speed is 30-40 rpm, turn on the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com