Preparation method of propionyloxy ethyl trimethyl ammonium chloride chitosan fiber

A technology of propionyloxyethyltrimethylammonium chloride and acryloyloxyethyltrimethylammonium chloride, which is applied in the directions of fiber processing, textile and papermaking, etc., can solve the problem of unsatisfactory effect and poor liquid absorption , weak antibacterial properties of chitosan fibers, etc., to achieve the effect of increasing polycationic properties, low cost, and promoting wound healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

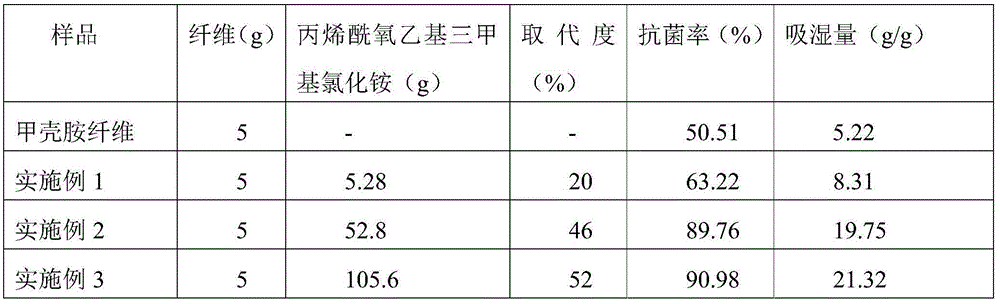

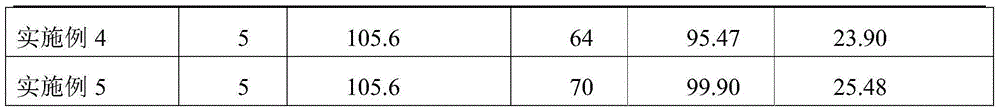

Embodiment 1

[0033]Weigh 5 g of chitosan fibers and disperse them in 125 mL of pyridine, stir at room temperature for 1 h, take out the chitosan fibers, and dry them in vacuum. Disperse the dried chitosan fiber in 250mL of methanol, add 5.28g of acryloyloxyethyltrimethylammonium chloride, stir evenly at room temperature, and react in a constant temperature water bath at 60°C for 24h. Chitosan fibers are separated from the reaction mixture liquid, and the isolated chitosan fibers are dispersed in 80% (V / V) methanol aqueous solution, 15% (V / V) acetic acid aqueous solution is added dropwise, methanol and acetic acid aqueous solution are mixed Adjust the pH of the liquid to 7.2, shake for 30 minutes, separate the soaked chitosan fibers from the mixed solution, wash 3 times with 80% (V / V) methanol aqueous solution, and vacuum dry at 40°C after centrifugal dehydration , to obtain propionyloxyethyltrimethylammonium chloride chitosan fiber with a substitution degree of 20%.

Embodiment 2

[0035] Weigh 5 g of chitosan fibers and disperse them in 125 mL of 2-picoline, stir at room temperature for 6 h, take out the chitosan fibers, and dry them in vacuum. Disperse the dried chitosan fiber in 250mL of ethanol, add 52.8g of acryloyloxyethyltrimethylammonium chloride, stir evenly at room temperature, and react in a constant temperature water bath at 70°C for 48h, and the reacted Chitosan fiber is separated from the reaction mixture liquid, and the chitosan fiber separated is dispersed in 80% (V / V) ethanol aqueous solution, 15% (V / V) acetic acid aqueous solution is added dropwise, ethanol, acetic acid aqueous solution are mixed Adjust the pH of the solution to 6.0, shake for 30 minutes, separate the soaked chitosan fiber from the mixed solution, wash 3 times with 80% (V / V) ethanol aqueous solution, centrifuge and dehydrate, and vacuum dry at 40 ° C. , to obtain propionyloxyethyltrimethylammonium chloride chitosan fiber with a substitution degree of 46%.

Embodiment 3

[0037] Weigh 5 g of chitosan fibers and disperse them in 125 mL of 3-picoline, stir at room temperature for 12 h, take out the chitosan fibers, and dry them in vacuum. Disperse the dried chitosan fiber in 250mL of propanol, add 105.6g of acryloyloxyethyltrimethylammonium chloride, stir evenly at room temperature, and react in a constant temperature water bath at 80°C for 72h. The chitosan fiber and the reaction mixture liquid are separated, and the chitosan fiber that is separated is dispersed in 80% (V / V) acetone aqueous solution, is added dropwise 15% (V / V) acetic acid aqueous solution, acetone, acetic acid aqueous solution The pH of the mixed solution was adjusted to 7.5, shaken for 30min, then the soaked chitosan fiber was separated from the mixed solution, washed 3 times with 80% (V / V) acetone aqueous solution, and after centrifugal dehydration, vacuum at 40°C Dry to obtain propionyloxyethyltrimethylammonium chloride chitosan fiber with a substitution degree of 52%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com