Method for measuring stress optical coefficient of optical thin film

An optical coefficient, optical thin film technology, applied in the field of film stress optical coefficient measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

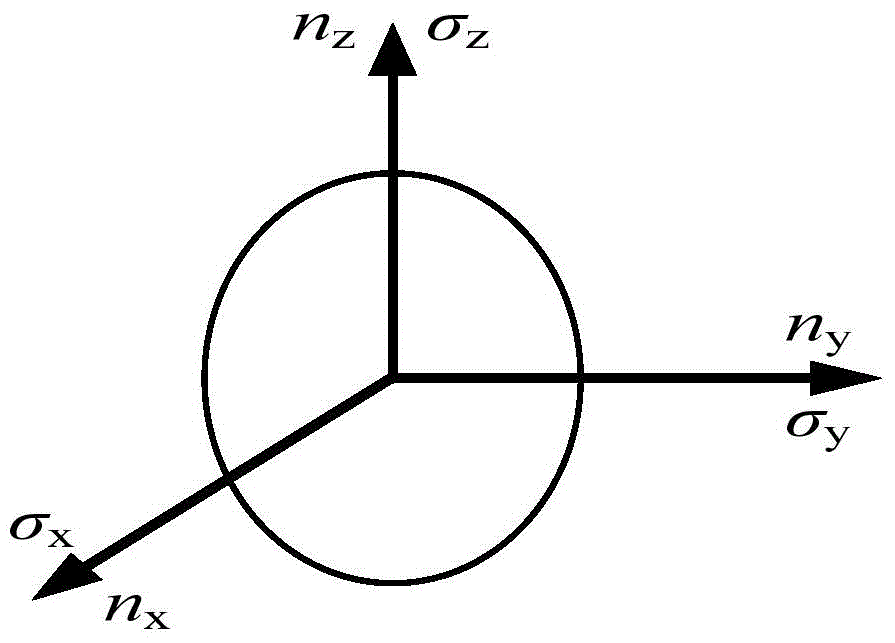

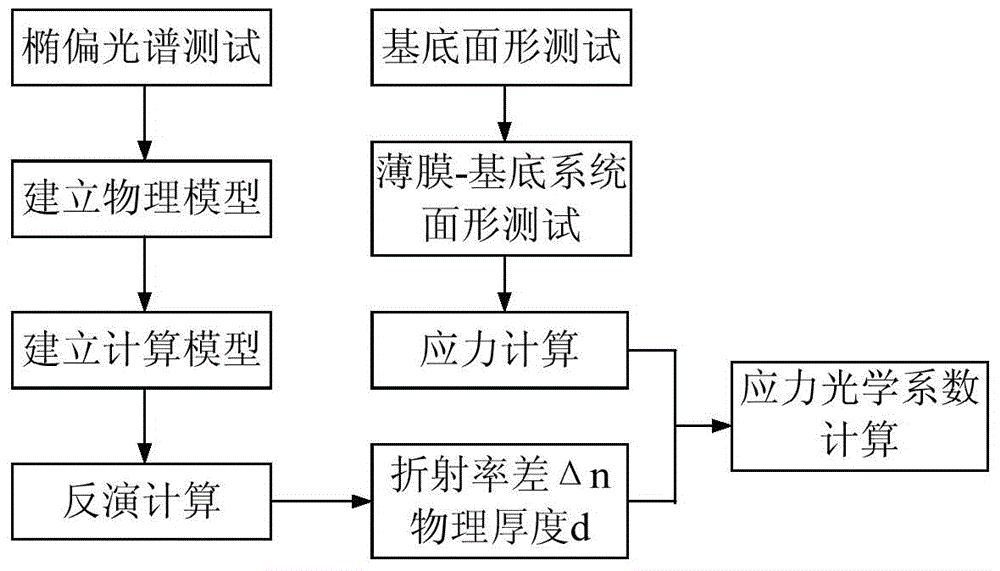

Method used

Image

Examples

Embodiment 1

[0068] 1. Measuring method of stress optical constant of silicon dioxide film:

[0069] 1) Deposit silicon dioxide film by ion beam sputtering. The substrate material is a single-sided polished Φ25×1mm quartz wafer and an ultra-smooth surface Φ40×1mm silicon wafer. The surface roughness of the silicon wafer is less than 0.3nm, and the surface of the quartz wafer is The roughness is less than 1nm; the silicon wafer and the quartz wafer are completed under the same equipment and the same process parameters.

[0070] 2) Use a high-temperature test box to heat-treat the samples separately. The heat-treatment temperatures are 150°C, 250°C, 350°C, 450°C, 450°C, 550°C, and 650°C. The heat-treatment time is 24 hours, and the heating rate is 5°C / min. .

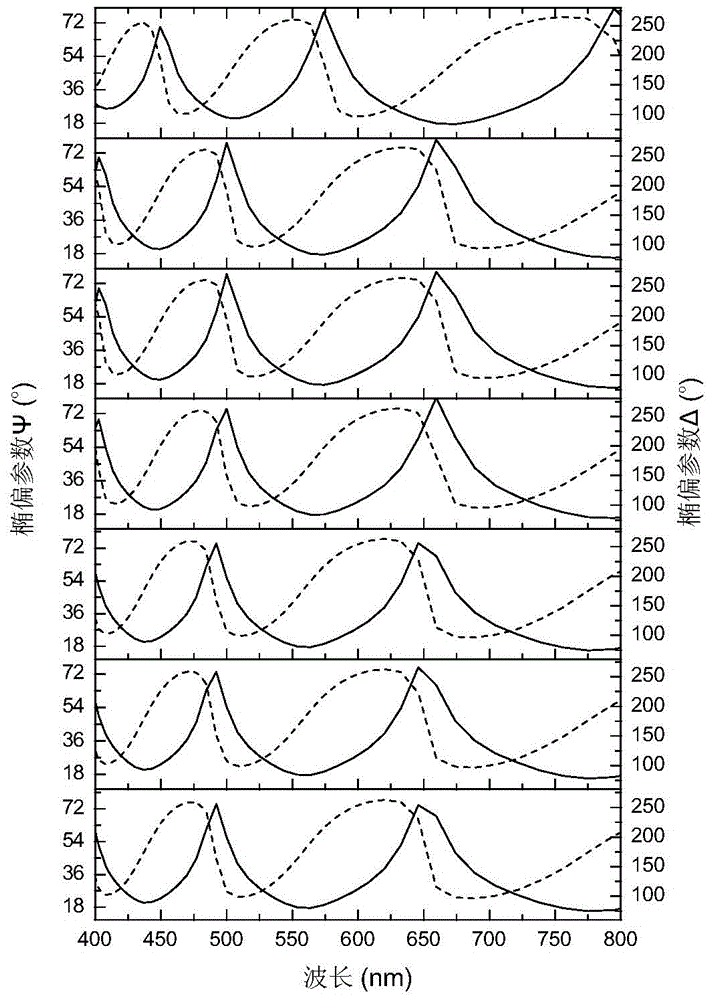

[0071] 3) Measure the reflection ellipsometric parameters Ψ(λ) and Δ(λ) of the silicon dioxide film with an ellipsometer, set the measurement wavelength range to 400nm-800nm, the measurement step size to 5nm, and the incident angle to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com