Coloring method for wrought aluminum alloy welded joint color metallography

A technology for deformed aluminum alloys and welded joints, which is applied to measuring devices, instruments, and material analysis through optical means. Weld corrosion and other problems, to achieve the effect of low cost, high accuracy, clear grain boundary

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Add 0.5 g of potassium chloride, 32 ml of 35% phosphoric acid solution and 10 ml of 37% hydrochloric acid solution into 280 ml of deionized water and mix to obtain an acid etching solution;

[0035] 2) Heat the acid etching solution to 55°C, drop the solution on the surface of the ground and polished welding wire ER4043 filled weld specimen for 60 seconds, rinse with a large amount of deionized water, and dry with hot air;

[0036] 3) Immerse the acid-etched specimen completely in the Weck reagent and shake gently for 5 seconds. After the surface is colored, rinse it with a large amount of deionized water and dry it with hot air.

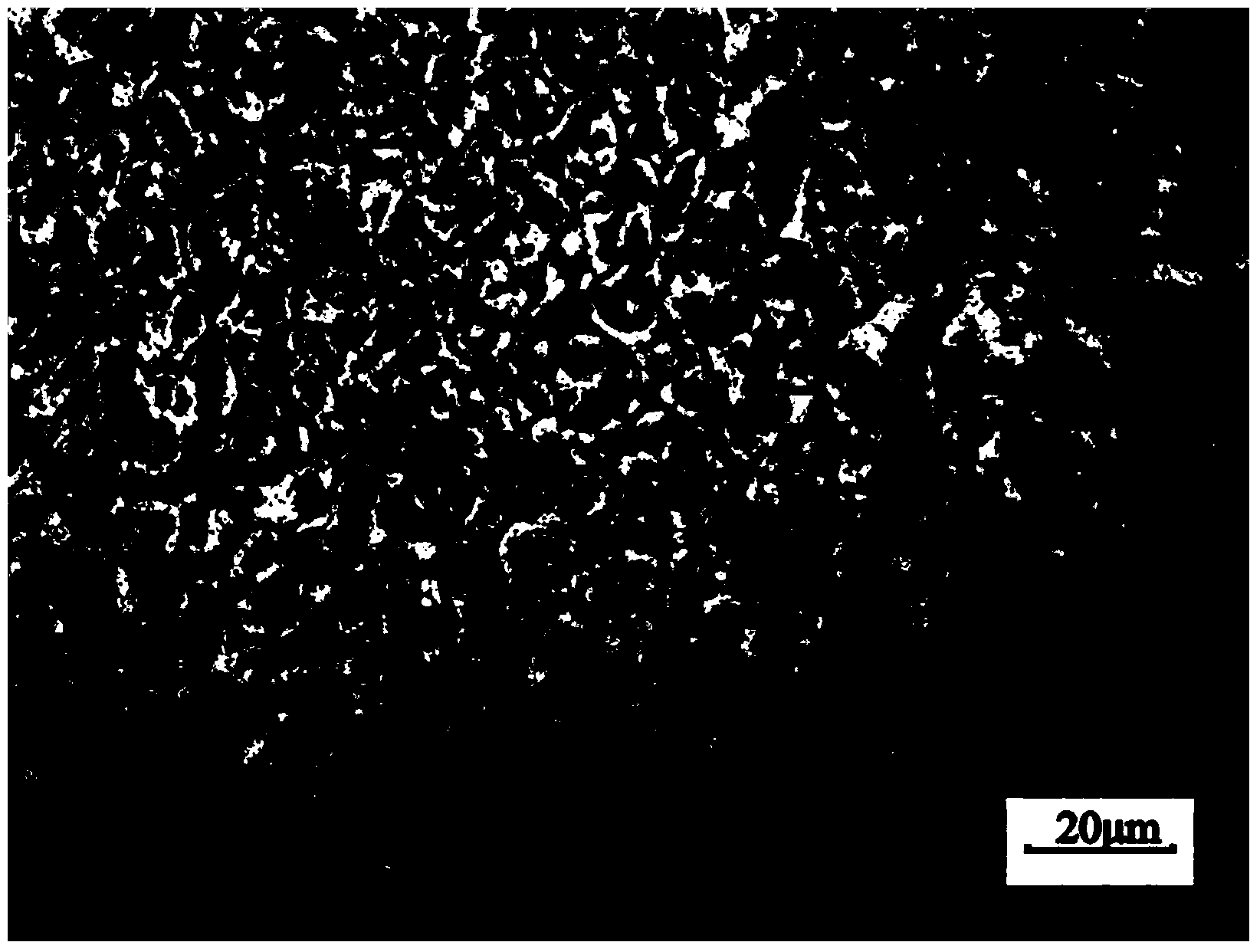

[0037] Metallographic photographs obtained as figure 1 shown, from figure 1 Clear grain boundaries and grain morphology can be seen in the welding wire ER4043 filled weld.

Embodiment 2

[0039] 1) Add 1.8 g of potassium chloride, 32 ml of 35% phosphoric acid solution and 10 ml of 37% hydrochloric acid solution into 280 ml of deionized water and mix to obtain an acid etching solution;

[0040] 2) Add 1g of NaOH solid to 250ml of deionized water and mix to obtain an alkali etching solution;

[0041] 3) Heat the acid etching solution to 65 ° C, drop the solution on the surface of the ground and polished multi-layer multi-pass welding wire ER5356 filled weld specimen for 60 seconds, rinse with a large amount of deionized water, and dry with hot air;

[0042] 4) Heat the alkaline etching solution to 50°C, immerse the acid-etched specimen in the alkaline etching solution for 100s, rinse with a large amount of deionized water, and dry with hot air;

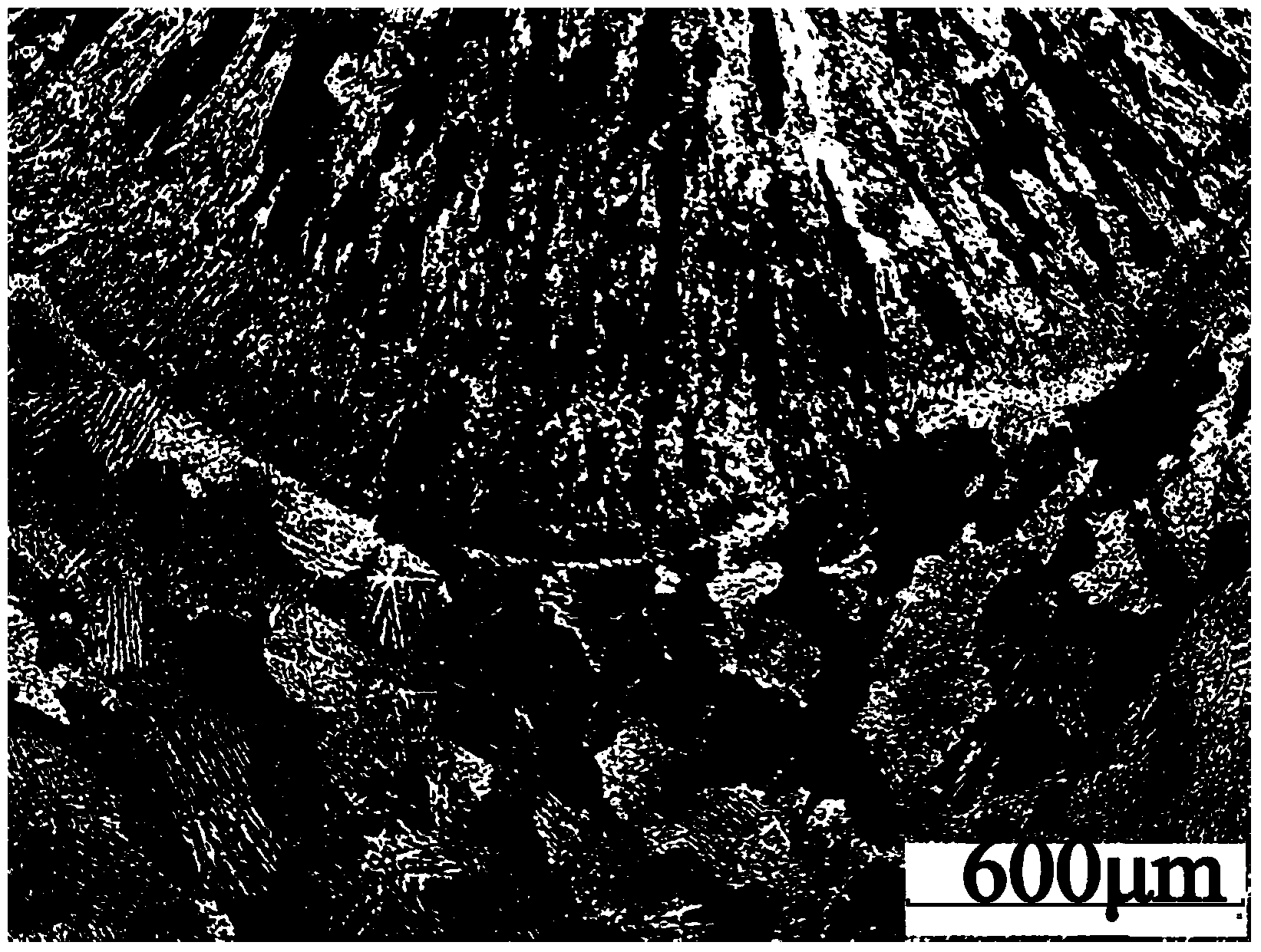

[0043] 5) Completely immerse the test piece after alkali etching treatment in Weck reagent and shake gently for 10 seconds. After the surface is colored, rinse it with a large amount of deionized water and dry it with ho...

Embodiment 3

[0046] 1) Add 1.2 g of potassium chloride, 25 ml of 35% phosphoric acid solution and 10 ml of 37% hydrochloric acid solution into 280 ml of deionized water and mix to obtain an acid etching solution;

[0047] 2) Add 3g of NaOH solid to 250ml of deionized water and mix to obtain an alkali etching solution;

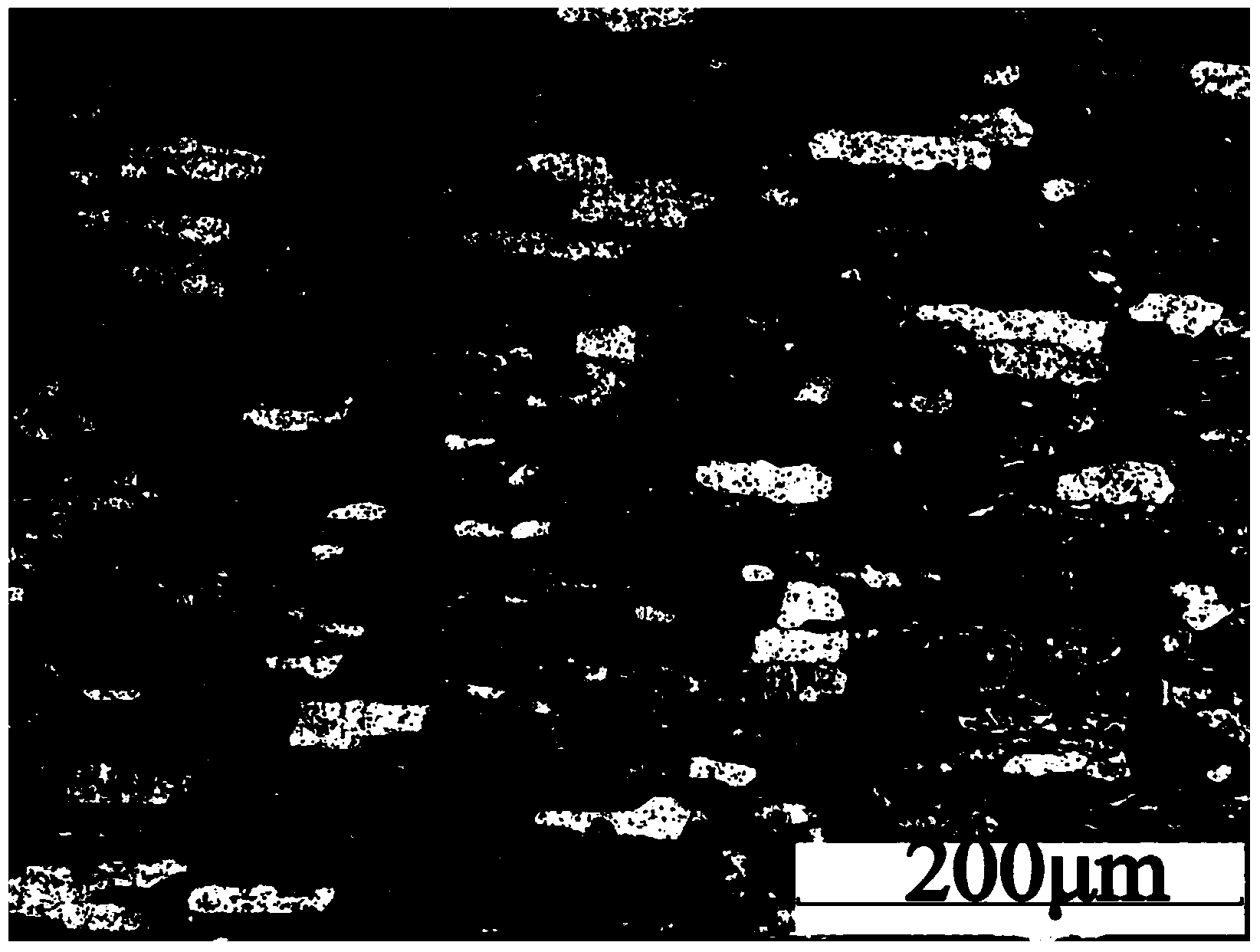

[0048] 3) Heat the acid etching solution to 60°C, drop the solution on the surface of the heat-affected zone specimen after grinding and polishing the welded 7N01 aluminum alloy for 50 seconds, rinse it with a large amount of deionized water, and dry it with hot air;

[0049] 4) Heat the alkaline etching solution to 40°C, immerse the acid-etched specimen in the alkaline etching solution and vibrate ultrasonically for 60s, rinse with a large amount of deionized water, dry with hot air, and the ultrasonic frequency is 15kHz;

[0050] 5) Completely immerse the test piece after alkali etching treatment in Weck reagent and shake gently for 5 seconds. After the surface is colored...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com