Passive safe cooling system

A cooling system and a passive technology, applied in the field of nuclear power plant reactor safety equipment, can solve the problems of high construction cost, high safety performance, and the inability to bring heat outside the containment, so as to reduce construction costs and operation and maintenance costs, reduce equipment purchases, reduce The effect of the number of devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

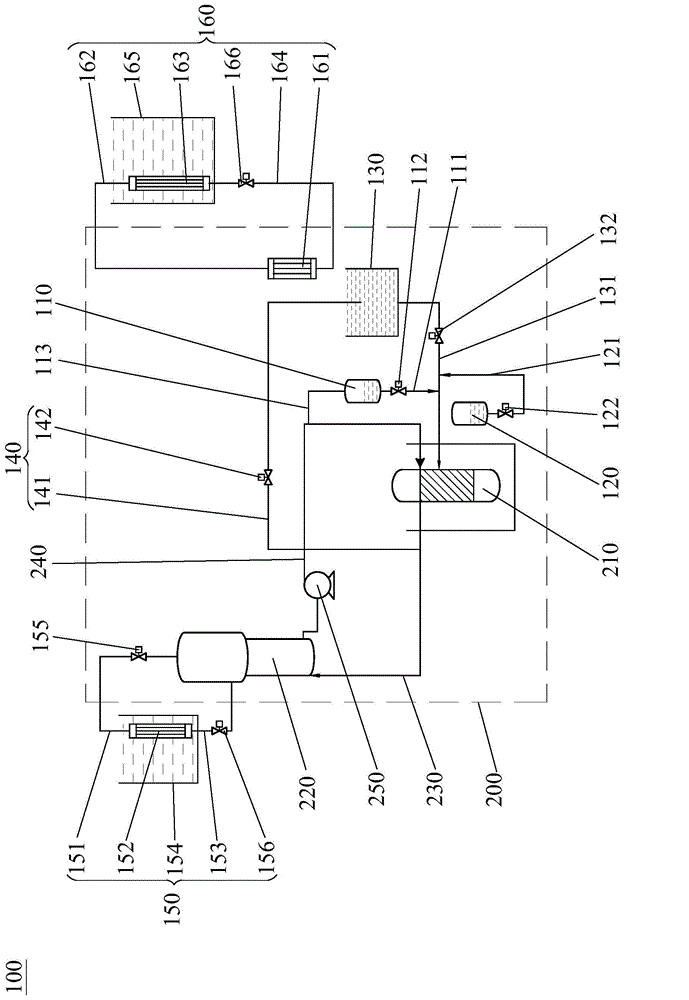

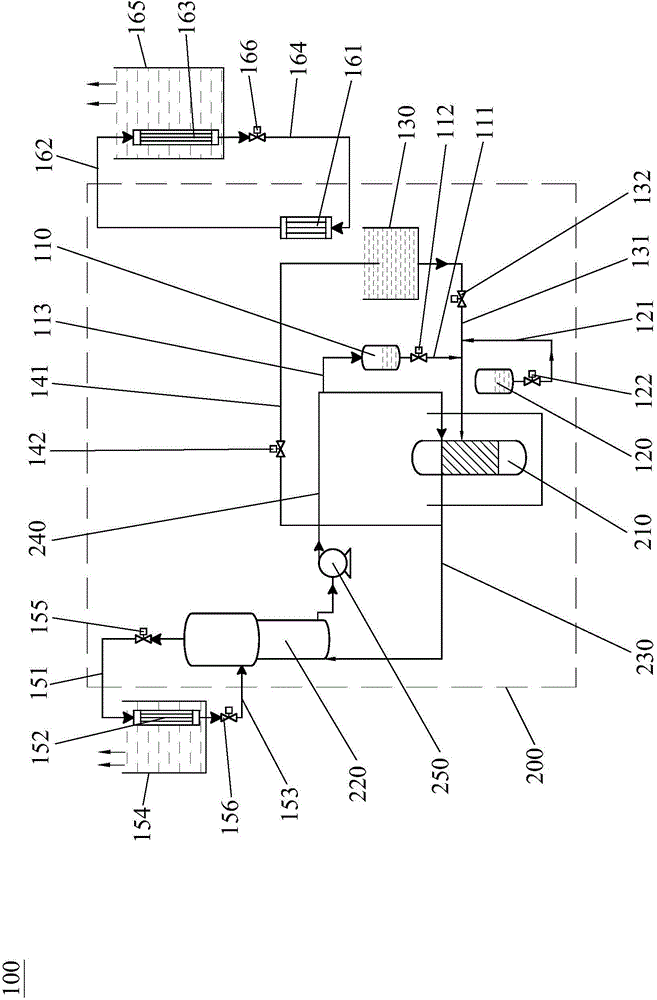

[0026] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. The passive safety cooling system 100 provided by the present invention is mainly applicable to PWR nuclear power plants with a concrete containment 200 of 300,000 to 2,000,000 kilowatts (electric power), but not limited thereto.

[0027] Such as figure 1 As shown, the concrete containment vessel 200 is provided with a pressure vessel 210 and a steam generator 220. The pressure vessel 210 and the steam generator 220 are connected by pipes, and the pipes form a hot pipe section 230 and a cold pipe section 240. The pipe section 240 is also provided with a primary circuit main pump 250 . The hot pipe section 230, the cold pipe section 240, the main pump 250, etc. form a loop, and a general nuclear power plant has more than one loop. figure 1 and figure 2 Only one loop is shown. When the nuclear power plant is in normal op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com