Automated Radiochemical Separation System for Burnup Measurement of Spent Fuel Elements

A radiochemical separation and spent fuel technology, applied in the field of automatic radiochemical separation system, can solve the problems of not being able to meet the needs of rapid measurement of component burnup, separation process yield, inconsistent decontamination factor, large dose of researchers, etc., to achieve The effect of shortening the time of dissolution and material liquid transfer, saving manpower consumption and shortening the seasoning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

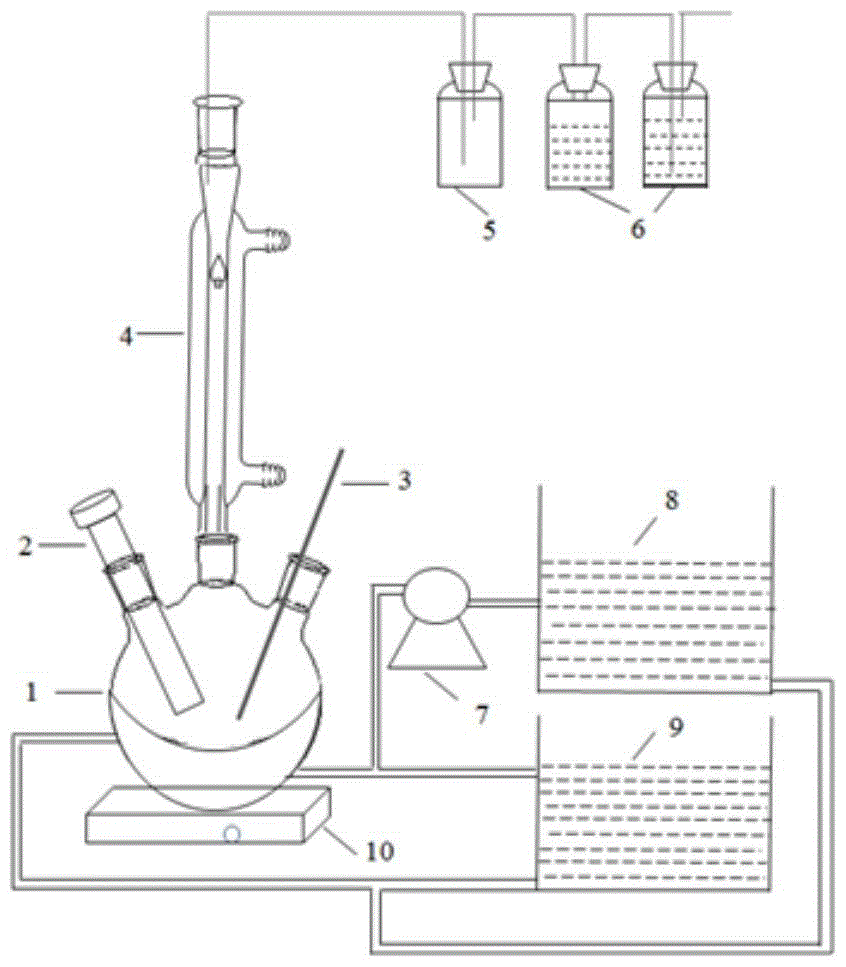

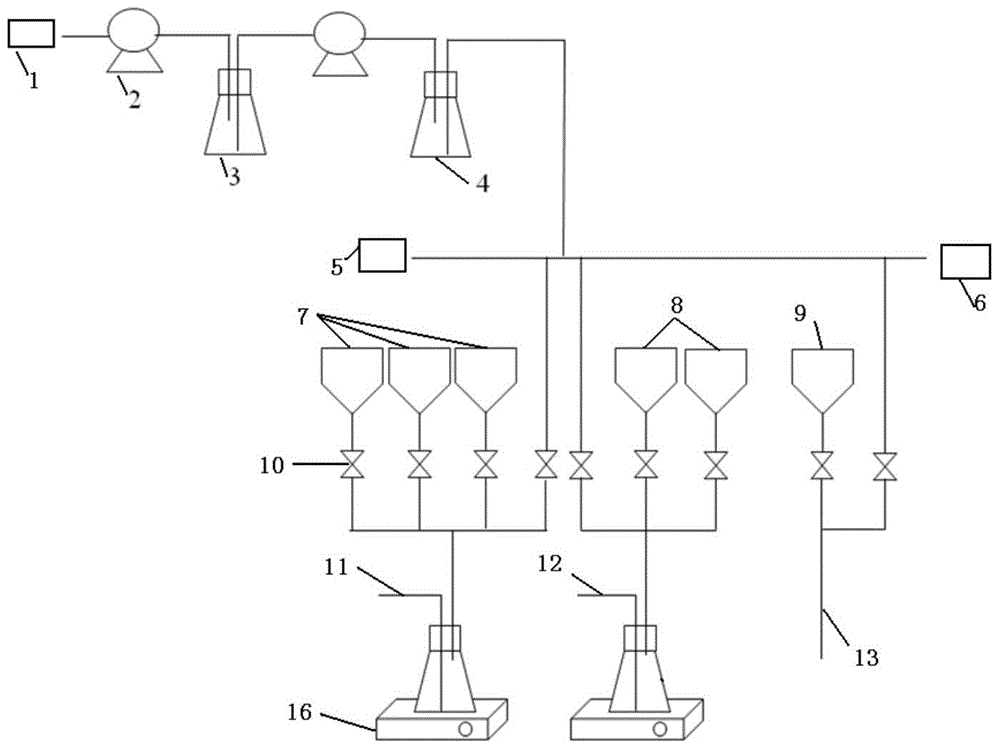

[0031] Automated radiochemical separation systems for burnup measurements of spent fuel elements, such as figure 1 and figure 2 shown. The system is composed of a dissolution unit, a seasoning unit, a separation unit and a control system. The dissolution unit, seasoning unit and separation unit are connected by a feed liquid delivery pipe; among them, the dissolution unit is as figure 1 As shown, the dissolver 1 is included, and the dissolver 1 is a double-layered round bottle-shaped structure with three necks, one of which is connected to the condenser tube 4, and the upper end of the condenser tube 4 is connected to the buffer bottle 5 and the liquid collection bottle 6 through a pipeline. Prevent the dissolving liquid from volatilizing into the environment during the dissolving process of the spent fuel element; one neck places the feeding pipe 2 with a honeycomb structure at the bottom, and the other neck inserts the feeding liquid delivery pipe 3 to realize the connecti...

Embodiment 2

[0061] The device and operation method are the same as in Example 1, except that the temperature of the high-temperature water bath is 75° C., and the temperature of the low-temperature water bath is 25° C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com