High-voltage switch device and arc extinguish chamber and tank of high-voltage switch device

An arc-extinguishing chamber and tank technology, which is applied to high-voltage/large-current switches, electrical switches, high-voltage air circuit breakers, etc., can solve the problems of reducing the temperature of insulating gas, decreasing the insulating capacity, and increasing the pressure of insulating gas, so as to improve the insulation. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

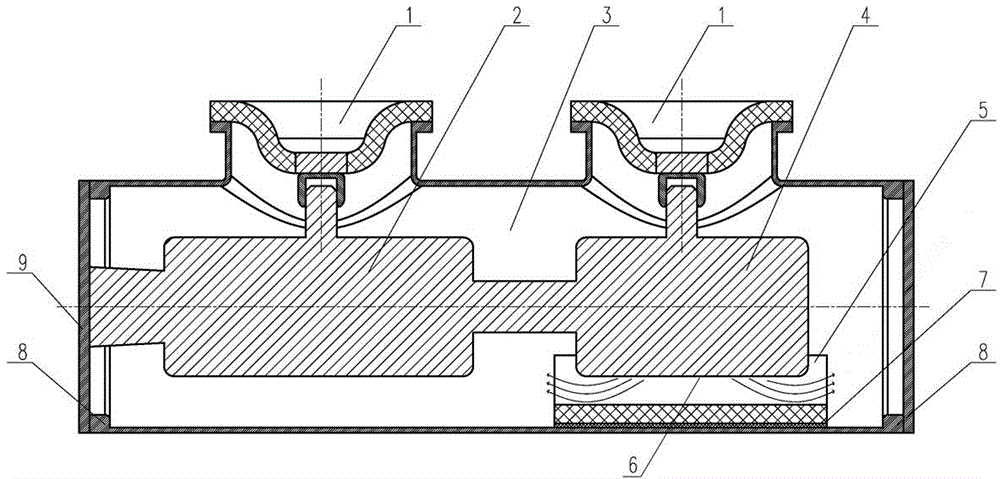

[0024] The embodiment of high voltage switchgear in the present invention: as figure 1 As shown, the high-voltage switchgear is a high-voltage circuit breaker, including an arc extinguishing chamber and an operating mechanism connected by transmission on it. The structure of the operating mechanism belongs to the prior art. 2 and static terminal 4 constitute. The tank body is composed of a tank body 3 and a solid insulating layer. The tank body 3 extends along the left and right directions. The static terminal 4 is arranged coaxially opposite to each other in the tank body 3 , and at the bottom side of the outer peripheral surface of the static terminal 4 there is an orifice blowing side 6 with the opening facing downward. The solid insulating layer is a sheet-like layer 5 relatively arranged below the blowing side 6. The sheet-like layer 5 is bonded and fixed on the inner wall surface of the tank body 3 through an adhesive layer. The sheet-like layer 5 adopts a class C heat-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com