Water-oxygen blocking film and packaging technology for flexible film electronic device

A technology for water-oxygen barrier films and electronic devices, which is applied in electric solid devices, electrical components, semiconductor devices, etc., can solve problems such as continuous growth of defects, and achieve the effect of thin thickness and good water sample barrier performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

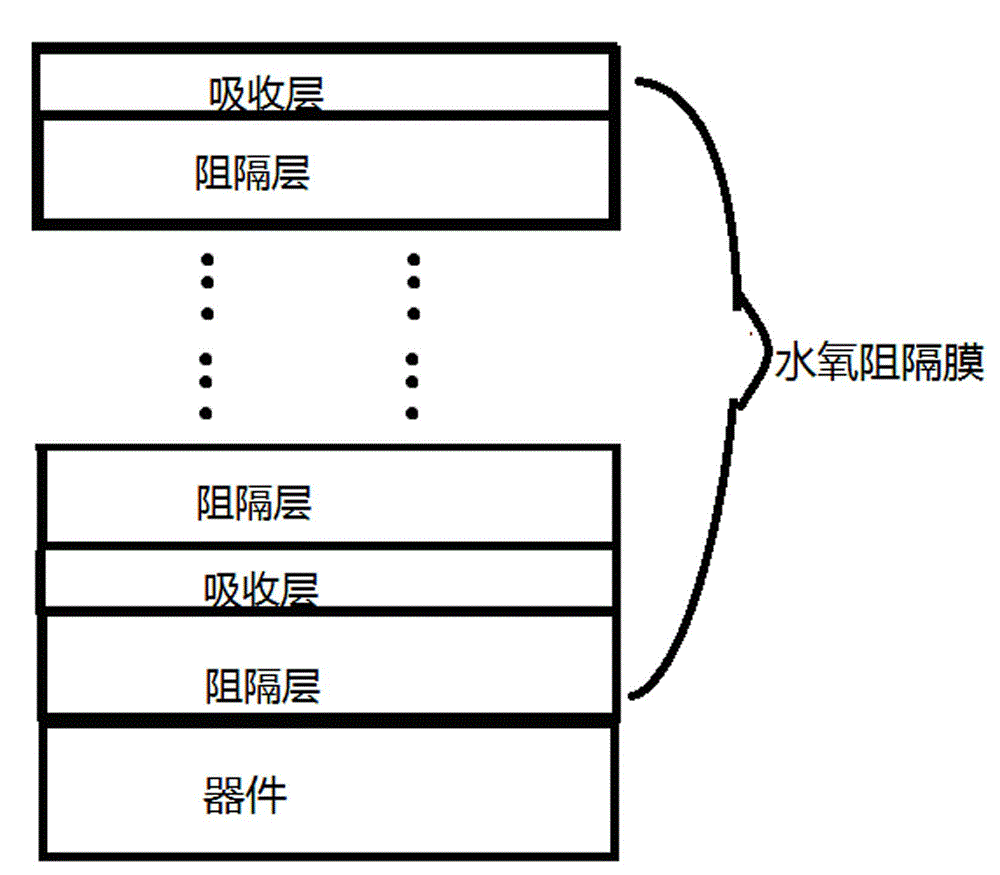

[0035] A water-oxygen barrier film for flexible thin-film electronic devices, such as figure 1 As shown, the composite film is composed of multiple layers of barrier layers for blocking water and oxygen molecules and multiple layers of absorbing layers for decoupling and absorbing water and oxygen molecules. Both the barrier layer and the absorbing layer are inorganic films, and the composite film It is a pure inorganic composite film. The overall thickness of the composite film is not greater than 1 micron, at 30 o C. Under the condition of 100% relative humidity, it should not be higher than 6.52×10 -4 g / m 2 / day water vapor transmission rate.

[0036] The composite film includes the bottom layer in contact with the device, the top layer in contact with the atmosphere, and an intermediate layer arranged between the bottom layer and the top layer. Both the bottom layer and the top layer are barrier layers, and any adjacent two layers constituting the composite film The l...

Embodiment 2

[0048] A packaging method for flexible thin-film electronic devices, using the water-oxygen barrier film of Example 1 as the packaging layer, the packaged product has good water-oxygen barrier performance, and can achieve good water-oxygen barrier properties under a thinner structure. isolation performance.

Embodiment 3

[0050] The water and oxygen barrier films of three kinds of flexible thin film electronic devices were prepared for performance comparison, and the structures were as follows:

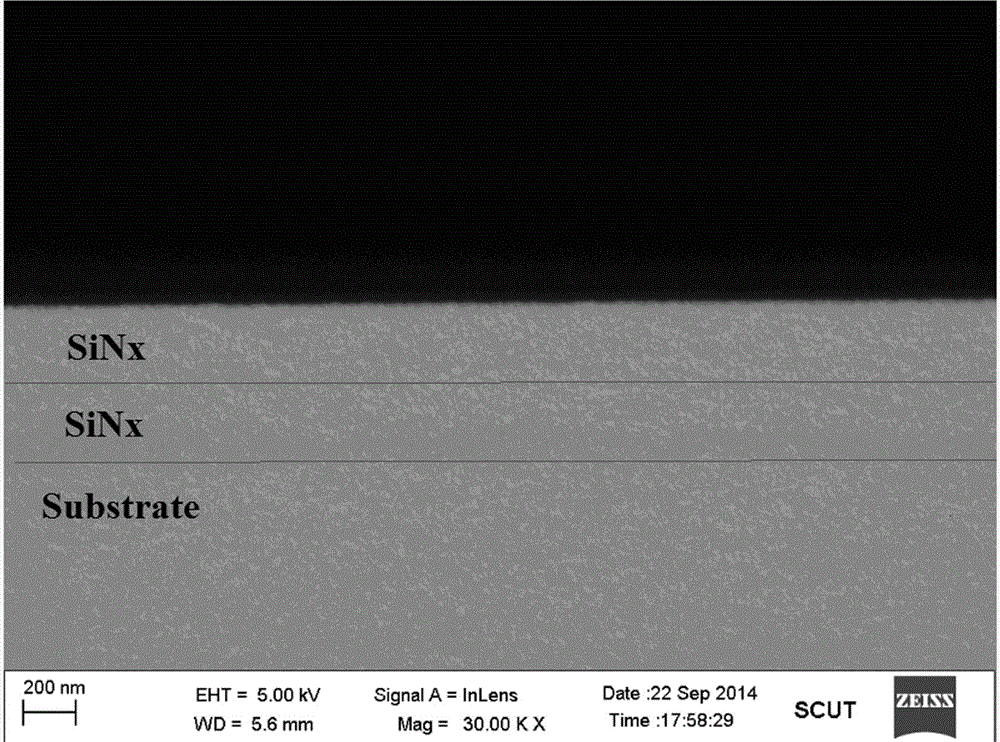

[0051] Sample 1): Si 3 N 4 (200nm) / Si 3 N 4 (200nm) / PEN;

[0052] Sample 2): Si 3 N 4 (200nm) / IZO (30nm) / Si 3 N 4 (200nm) / PEN;

[0053] Sample 3): Si 3 N 4 (200nm) / IZO (30nm) / Si 3 N 4 (200nm) / IZO (30nm) / Si 3 N 4 (200nm) / IZO (30nm) / Si 3 N 4 (200nm) / PEN.

[0054] where Si 3 N 4 The film was deposited by PECVD equipment, the film deposition temperature was 80 °C, the power was 150 W, and NH 3 , N 2 、SiH 4 mixed gas as the reaction gas.

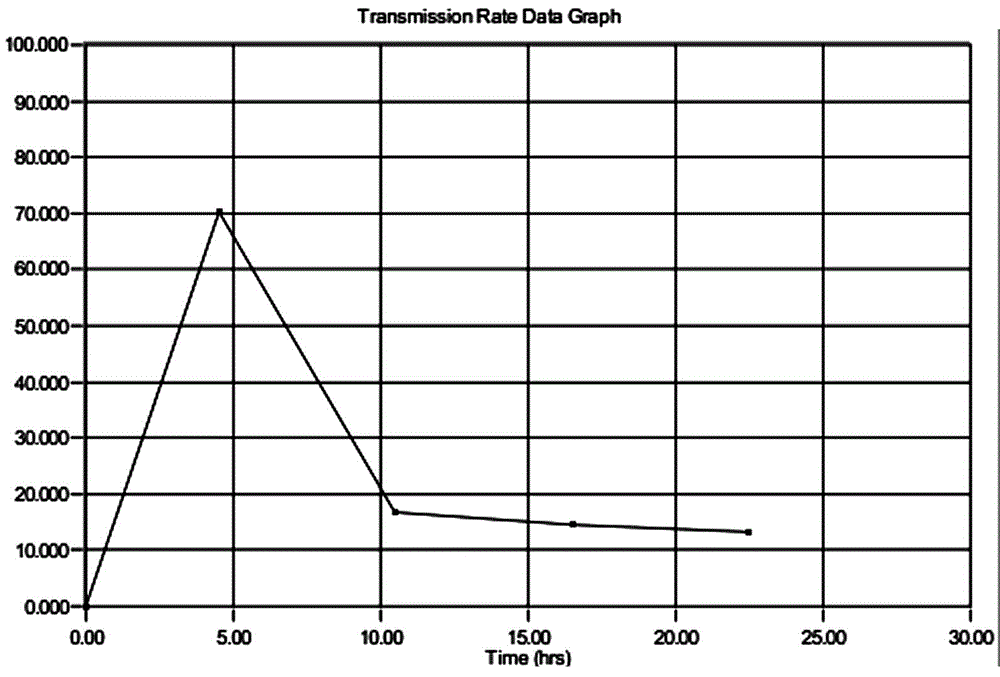

[0055] The Mocon (Aquatran® Model 2) method was used to measure the water-oxygen barrier coefficient WVTR performance at 38°C and 100% relative humidity.

[0056] The WVTR test results and SEM images of the three samples are as follows: Figure 2 to Figure 8 shown.

[0057] The WVTR test value of sample 1 is 1.3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com