A kind of LED electrode structure and manufacturing method thereof

A technology of electrode structure and manufacturing method, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of unstable electrochemical properties of Ag, sensitive preparation process, easy electrode falling off, etc., so as to improve external quantum efficiency and improve luminescence. Efficiency, reasonable structure design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

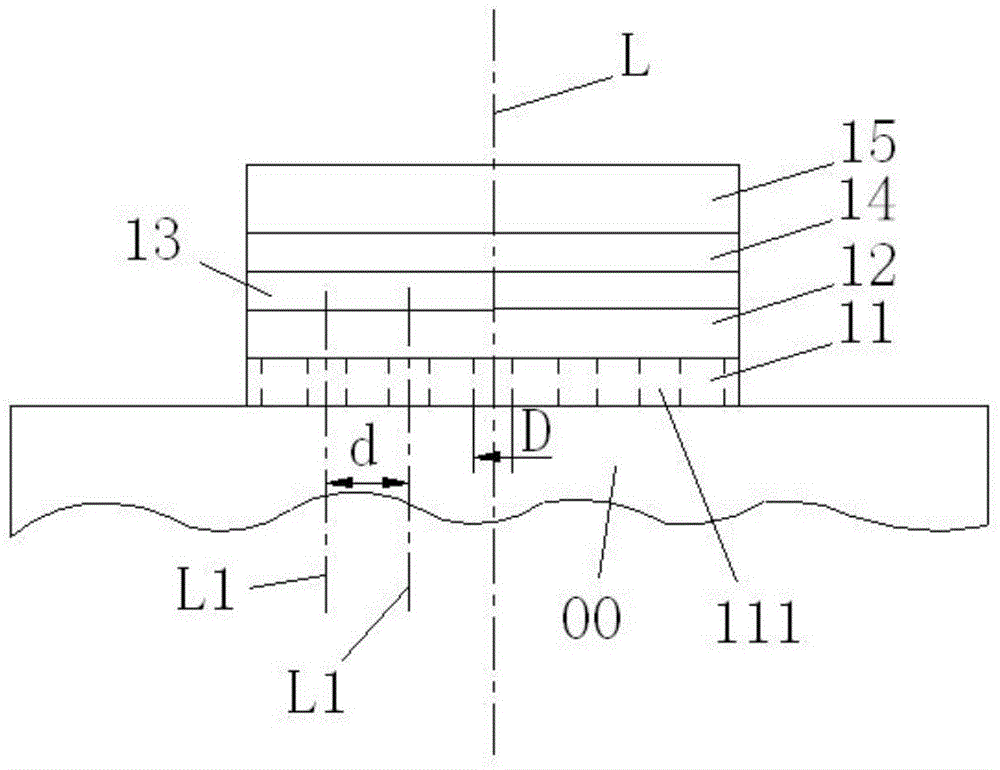

[0038] A LED electrode structure, see figure 1 , comprising a first Ni layer 11, an Al layer 12, a Cr layer 13, a second Ni layer 14 and an Au layer 15, the first Ni layer 11 is plated on the GaN layer 00 comprising n-GaN or / and p-GaN On the surface layer, the Al layer 12 is plated on the first Ni layer 11, the Cr layer 13 is plated on the Al layer 12, and the second Ni layer 14 is plated on the Cr layer 13, so The Au layer 15 is located on the outermost layer and plated on the second Ni layer 14 .

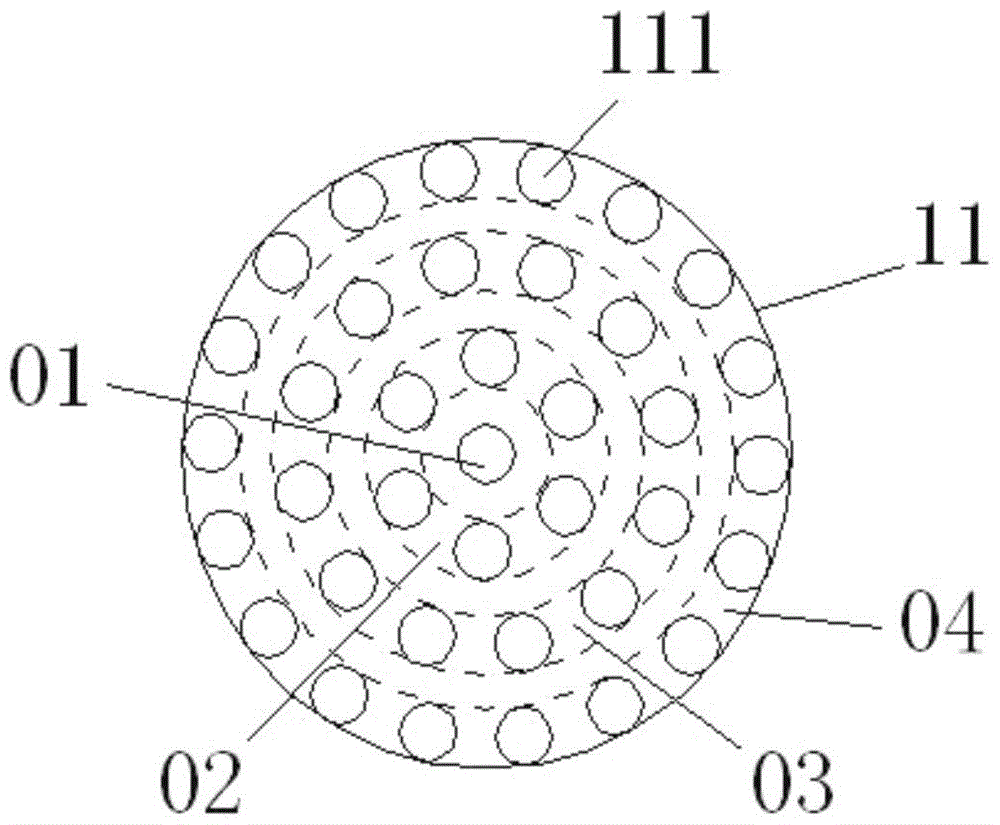

[0039] The first Ni layer 11 is provided with a through hole 111 along the central axis L of the LED electrode; on a plane perpendicular to the central axis L of the LED electrode, the cross section of the through hole 111 is circular; The number of through holes 111 is 37, which are uniformly arranged in the first row 01, the second row 02, the third row 03 and the fourth row 04 centered on the central axis L of the LED electrode from the inside to the outside. The number of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com