Composite absorbent paper for absorbent sanitation products and preparation method and application of composite absorbent paper

A hygienic product and absorbent technology, applied in the field of composite absorbent paper for absorbent products, can solve the problems of reduced wearing comfort, reduced surface dryness, affected absorption speed, etc., to improve adhesion performance, reduce leakage, lock water power effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085]

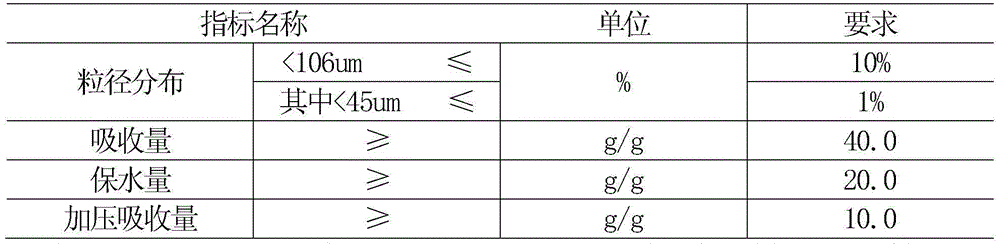

[0086] (1) Select Nippon Shokubai W211 polymer water-absorbing resin, the performance indicators are as follows

[0087]

[0088] (2) Pass through a vibrating sieve and sieve through a 40-mesh screen to form a finer polymer water-absorbent resin larger than 40 mesh and a coarser polymer water-absorbent resin smaller than 40 mesh.

[0089] (3) Adjust the angle of the polymer distribution plate under the first lower hopper so that the width below the formed limiting area is 50% of the width;

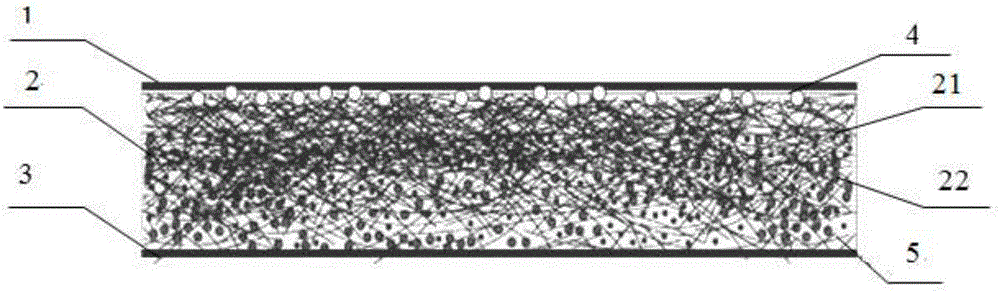

[0090] (3) Polymer water-absorbent resin less than 40 meshes is evenly spread on the compact surface of the high-loft non-woven fabric through the polymer lower hopper, and after being glued with the upper dust-free paper coated with hot-melt adhesive on the surface, it is pressed by a pressing roller ;

[0091] (4) Adjust the angle of the polymer distribution plate under the second lower hopper so that the width below the formed restricted area is 80% of the width;

[009...

Embodiment 2

[0095] Absorbent Paper Specifications

[0096]

[0097] (1) Select Nippon Shokubai W211 high-molecular water-absorbing resin, prepare and manufacture according to the existing technology without screening.

[0098] (2) According to the amount of polymer added in the upper layer, it is evenly spread on the compact surface of the high-loft non-woven fabric through the polymer lower hopper, and after being glued with the upper dust-free paper coated with hot-melt adhesive, it is pressed by a pressing roller;

[0099] (4) According to the amount of polymer added in the lower layer, it is evenly spread on the fluffy surface of the high-loft non-woven fabric through the polymer lower hopper, and the polymer water-absorbing resin enters the fluffy surface through horizontal vibration, and the lower non-woven fabric sprayed with hot melt adhesive on the surface After the dust paper is glued and pressed by the pressing roller;

[0100] (5) Slitting and rewinding are vested.

Embodiment 3

[0102]

[0103]

[0104] (1) Select Nippon Shokubai W101 polymer water-absorbing resin, the performance indicators are as follows

[0105]

[0106] Vibrating sieve, screened by 20-mesh, 40-mesh, and 80-mesh sieves to form 20-40 mesh thicker polymer water-absorbent resin and 40-80 mesh finer polymer water-absorbent resin.

[0107] (2) Adjust the angle of the polymer distribution plate under the first lower hopper so that the width below the formed limit area is 50% of the width;

[0108] (2) Polymer water-absorbent resin of 20-40 meshes is evenly spread on the compact surface of the high-loft non-woven fabric through the polymer lower hopper, and after being glued with the upper dust-free paper coated with hot-melt adhesive on the surface, it is pressed by pressing rollers combine;

[0109] (3) Adjust the angle of the polymer distribution plate under the second lower hopper so that the width below the formed limit area is 40% of the width;

[0110] (3) The 40-80 mesh p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com