A preparation method of targeted temperature-controlled silibinin-loaded thermosensitive liposome-microbubble complex drug delivery system

A technology of drug delivery system and liposome, which is applied in the field of preparation of silibinin-loaded thermosensitive liposome-microbubble complex drug delivery system, which can solve the problems of tumor residue and achieve high-efficiency release and good temperature control The effect of the characteristic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

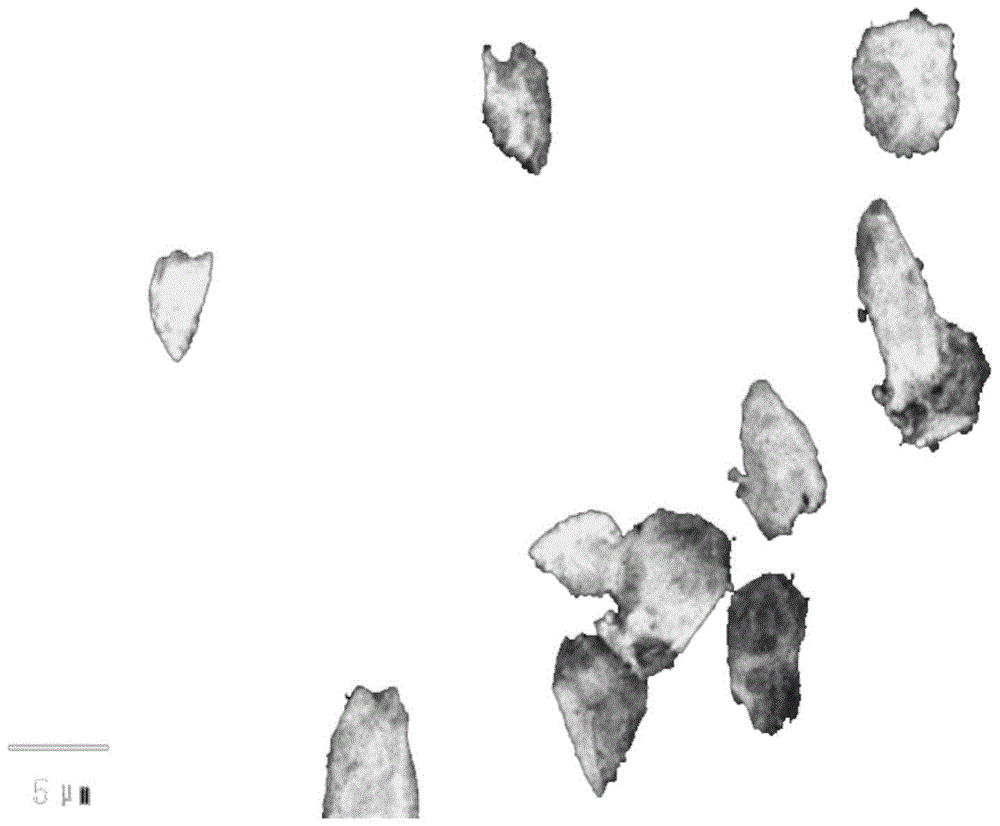

Image

Examples

Embodiment 1

[0026] 1) Preparation of silibinin-loaded thermosensitive liposomes

[0027] 30mg monopalmitoylphosphatidylcholine (DPPC), 3mg dipalmitoylphosphatidylcholine (MPPC), 5mg distearoylphosphatidylethanolamine-polyethylene glycol-amino (DSPE-PEG2000-Amine) and 2mg water Silybin was dissolved in 5mL of absolute ethanol to obtain a raw material solution. The raw material solution was prepared into a thin film with a rotary evaporator at 25° C. (formed in 1000mL water) dissolved film, and then after ultrasonic dispersion, microporous membrane filtration, phosphate buffer dialysis to obtain a solution containing water-loaded silibinin thermosensitive liposomes; wherein ultrasonic dispersion is in an ice bath The ultrasonic power was 100W, and the ultrasonic time was 10min; the microporous membrane filtration was performed three times with microporous membranes with a pore size of 0.8 μm and 0.4 μm; The solution is dialysate, which is changed every 8 hours and dialyzed for 48 hours to ...

Embodiment 2

[0033] 1) Preparation of silibinin-loaded thermosensitive liposomes

[0034] 20mg monopalmitoylphosphatidylcholine (DPPC), 2mg dipalmitoylphosphatidylcholine (MPPC), 3mg distearoylphosphatidylethanolamine-polyethylene glycol-amino (DSPE-PEG2000-Amine) and 3mg water Silybin was dissolved in 6mL of absolute ethanol to obtain a raw material solution. The raw material solution was prepared into a thin film with a rotary evaporator at 20° C. (formed in 1000mL water) dissolved film, and then after ultrasonic dispersion, microporous membrane filtration, phosphate buffer dialysis to obtain a solution containing water-loaded silibinin thermosensitive liposomes; wherein ultrasonic dispersion is in an ice bath The ultrasonic power was 80W, and the ultrasonic time was 5min; the microporous membrane filtration was performed three times with microporous membranes with a pore size of 0.6 μm and 0.2 μm; The solution is dialysate, which is changed every 4 hours and dialyzed for 72 hours to re...

Embodiment 3

[0040] 1) Preparation of silibinin-loaded thermosensitive liposomes

[0041] Mix 50mg monopalmitoylphosphatidylcholine (DPPC), 8mg dipalmitoylphosphatidylcholine (MPPC), 8mg distearoylphosphatidylethanolamine-polyethylene glycol-amino (DSPE-PEG2000-Amine) and 10mg water Silybin was dissolved in 20mL of absolute ethanol to obtain a raw material solution. The raw material solution was prepared into a film with a rotary evaporator at 30° C. (formed in 1000mL water) dissolved film, and then after ultrasonic dispersion, microporous membrane filtration, phosphate buffer dialysis to obtain a solution containing water-loaded silibinin thermosensitive liposomes; wherein ultrasonic dispersion is in an ice bath The ultrasonic power was 120W, and the ultrasonic time was 15min; the microporous membrane filtration was performed three times with microporous membranes with a pore size of 0.7 μm and 0.3 μm; The solution is dialysate, which is changed every 10 hours and dialyzed for 60 hours t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com