A temperature-responsive covalent organic framework material functionalized with temperature-controlled ionic liquids and its preparation method

A technology of covalent organic framework and ionic liquid, which is applied in the field of heat-sensitive materials and covalent organic framework materials, can solve problems such as polymer incompatibility, and achieve the effects of simple preparation process, less environmental pollution and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

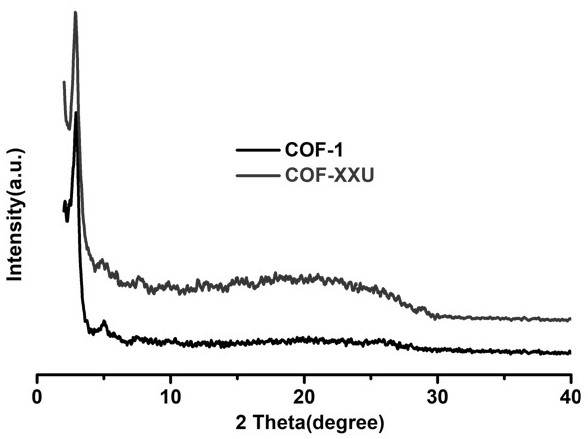

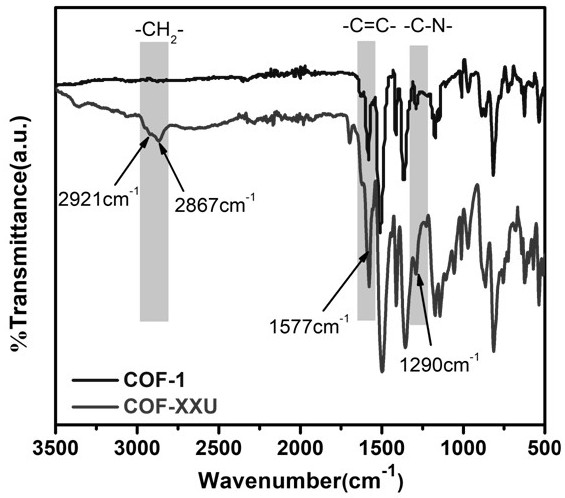

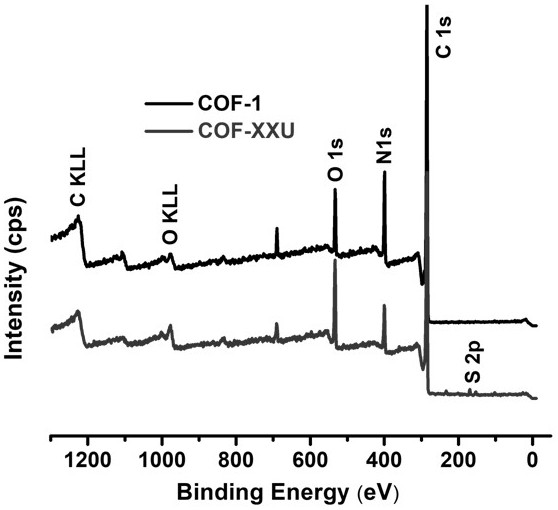

[0035] The covalent organic framework material COF-1 was synthesized by a solvothermal method, including the following steps:

[0036]45mg 2-hydroxyterephthalaldehyde and 159mg 4,4',4"-(1,3,5-triazine-2,4,6-triyl)triphenylamine were added to a 10mL pressure-resistant glass tube, and then A mixed solution of 1,4-dioxane / mesitylene / 6M acetic acid (1.5mL / 1.5mL / 0.5mL) was added, and the mixed system was sonicated for 20 minutes. After three freeze-vacuum-thaw cycles, The pressure-resistant glass tube was sealed, and then the solid obtained by reacting at 120 °C for 72 hours was washed with dimethylacetamide, water and ethanol, respectively, and the obtained solid was vacuum-dried at 80 °C for 24 hours to obtain a yellow covalent organic framework material COF -1.

Embodiment 2

[0038] The synthesis of covalent organic framework material COF-2 includes the following steps:

[0039] Disperse 44mg covalent organic framework material COF-1 in 10mL DMF, and then add 21mg catalyst anhydrous K 2 CO 3 , ultrasonicated for 20min, then added 184mg of dibromopolyethylene glycol 800, stirred at room temperature for 2 hours, refluxed at 80°C for 3 hours, the solid was washed with ethanol, and then vacuum-dried at 80°C overnight to obtain a yellow covalent organic Frame material COF-2.

Embodiment 3

[0041] The synthesis of covalent organic framework material COF-3 includes the following steps:

[0042] Disperse 26 mg of covalent organic framework material COF-2 into 10 mL of acetonitrile, then add 4 mg of methylimidazole, and react under reflux at 80 °C for 48 hours. After the mixture is cooled to room temperature, suction filtration, wash with ethanol, and vacuum dry at 80 °C for 12 hours. A yellow covalent organic framework material COF-3 was obtained within hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com