A kind of PEG-functionalized bis-imidazolium cation temperature-controlled ionic liquid and its preparation method and application

A technology of bisimidazolium cation and ionic liquid is applied in the field of temperature-controlled ionic liquid of bisimidazolium cation and its preparation, which can solve the problems of increasing impurities in ionic liquid, polychlorinated by-products, polluting the environment, etc., and achieves simple preparation process, chlorination Less by-products and less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

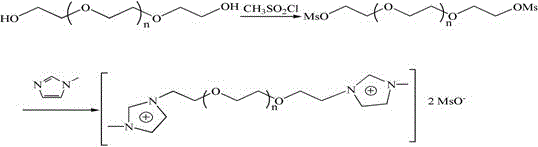

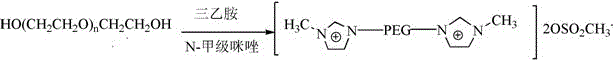

Method used

Image

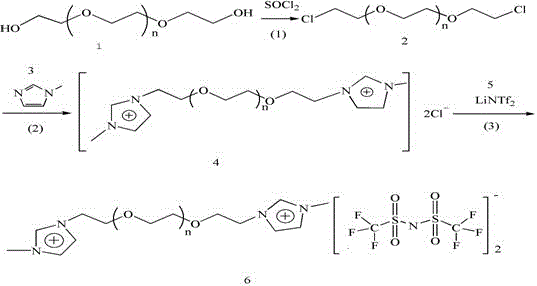

Examples

Embodiment 1

[0038] (1) Dissolve 31mmol of compound 1 in 100mL of anhydrous toluene to form solution 1, dissolve 62mmol of thionyl chloride and 62mmol of pyridine in 150mL of anhydrous toluene to form solution 2, and add solution 1 to solution 2 dropwise under nitrogen protection reaction at 60° C. for 2 hours, and then suction-filtered, an appropriate amount of anhydrous potassium carbonate was added to the filtrate to neutralize the acidic substances, suction-filtered, and rotary evaporated to obtain compound 2 (yield 90%).

[0039] Cl-PEG400 -Cl. 1 HNMR (D 2 O, δ / ppm ): 3.62-3.67(m35.1H(OCH 2 CH 2 ) 8.8 ) .

[0040] Cl-PEG 600 -Cl. 1 HNMR (D 2 O, δ / ppm ):3.64-3.69(m49.2H,(OCH 2 CH 2 ) 12.3 ).

[0041] Cl-PEG 800 -Cl. 1 HNMR (D 2 O, δ / ppm ):3.65-3.76(m69.6H,(OCH 2 CH 2 ) 17.4 ).

[0042] Cl-PEG 1000 -Cl. 1 H-NMR ((D 2 O, δ / ppm): 3.66-3.79 (m88.4H, (OCH 2 CH 2 ) 22.1 ).

[0043] (2) Under nitrogen protection, 20 mmol of compound 2 and 40 mmol of compound 3 were r...

Embodiment 2

[0054] (1) Dissolve 31mmol of compound 1 in 100mL of anhydrous chloroform to form solution 1, dissolve 93mmol of thionyl chloride and 93mmol of potassium carbonate in 150mL of anhydrous chloroform to form solution 2, and add solution 1 dropwise to the solution under nitrogen protection 2, reacted at 70°C for 3 hours, then suction filtered, added an appropriate amount of anhydrous potassium carbonate to the filtrate to neutralize acidic substances, suction filtered, and rotary evaporated to obtain compound 2 (yield 90%).

[0055] Cl-PEG 400 -Cl. 1 HNMR (D 2 O, δ / ppm ): 3.62-3.67(m35.1H(OCH 2 CH 2 ) 8.8 ) .

[0056] Cl-PEG 600 -Cl. 1 HNMR (D 2 O, δ / ppm ):3.64-3.69(m49.2H,(OCH 2 CH 2 ) 12.3 ).

[0057] Cl-PEG 800 -Cl. 1 HNMR (D 2 O, δ / ppm ):3.65-3.76(m69.6H,(OCH 2 CH 2 ) 17.4 ).

[0058] Cl-PEG 1000 -Cl. 1 H-NMR ((D 2 O, δ / ppm): 3.66-3.79 (m88.4H, (OCH 2 CH 2 ) 22.1 ).

[0059] (2) Under nitrogen protection, 20 mmol of compound 2 and 60 mmol of compound...

Embodiment 3

[0070] (1) Dissolve 31mmol of compound 1 in 100mL of anhydrous n-hexane to form solution 1, dissolve 124mmol of thionyl chloride and 124mmol of potassium bicarbonate in 150mL of anhydrous n-hexane to form solution 2, and dissolve 1 drop of the solution under nitrogen protection Added to solution 2, reacted at 80°C for 4 hours, then filtered with suction, added an appropriate amount of anhydrous potassium carbonate to the filtrate to neutralize acidic substances, filtered with suction, and rotary evaporated to obtain compound 2 (yield 90%).

[0071] Cl-PEG 400 -Cl. 1 HNMR (D 2 O, δ / ppm ): 3.62-3.67(m35.1H(OCH 2 CH 2 ) 8.8 ) .

[0072] Cl-PEG 600 -Cl. 1 HNMR (D 2 O, δ / ppm ):3.64-3.69(m49.2H,(OCH 2 CH 2 ) 12.3 ).

[0073] Cl-PEG 800 -Cl. 1 HNMR (D 2 O, δ / ppm ):3.65-3.76(m69.6H,(OCH 2 CH 2 ) 17.4 ).

[0074] Cl-PEG 1000 -Cl. 1 H-NMR ((D 2 O, δ / ppm): 3.66-3.79 (m88.4H, (OCH 2 CH 2 ) 22.1 ).

[0075] (2) Under nitrogen protection, 20 mmol of compound 2 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com