A kind of magnesium/magnesium solid-liquid composite casting molding method

A technology of solid-liquid compounding and casting molding, which is applied in the direction of belts/chains/gears, rotors, engine components, etc., can solve the problems of interface reaction layer thickness, complex process, many cracks and holes, etc., and achieve less defects such as cracks and holes , Excellent shear mechanical properties and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

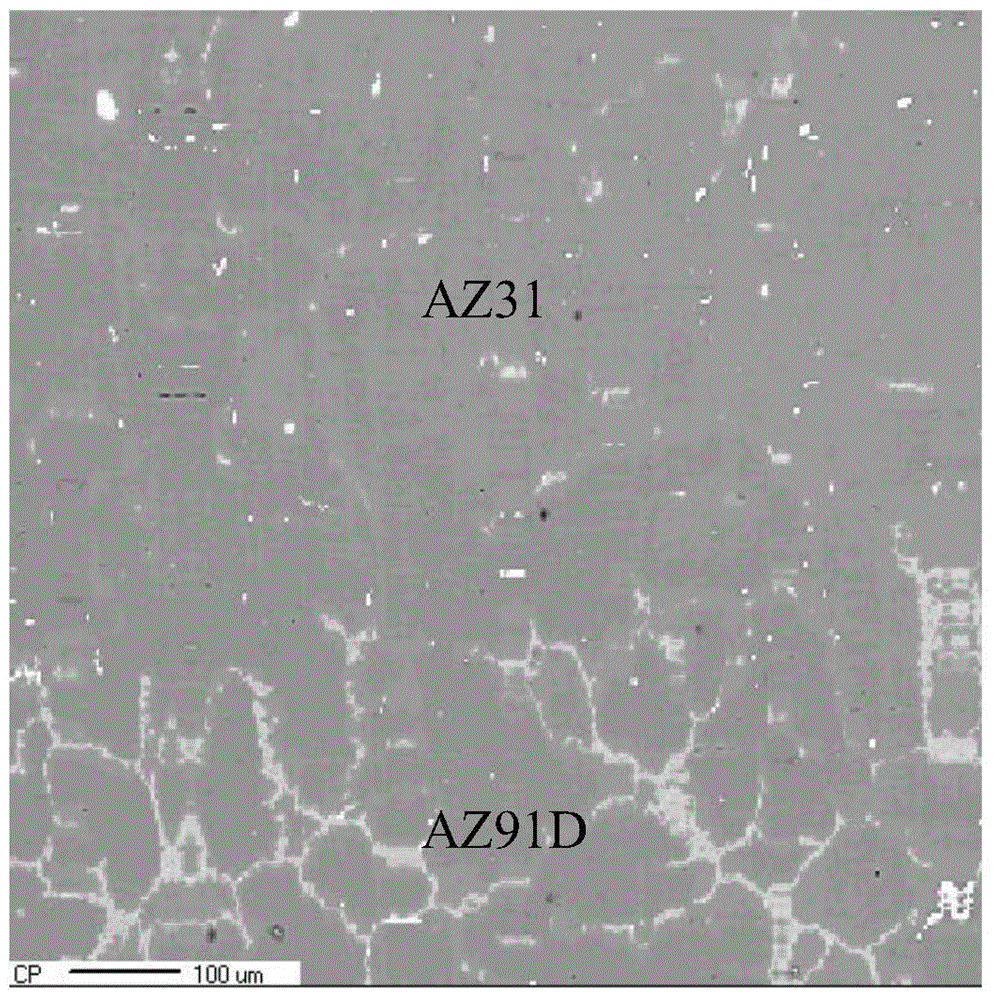

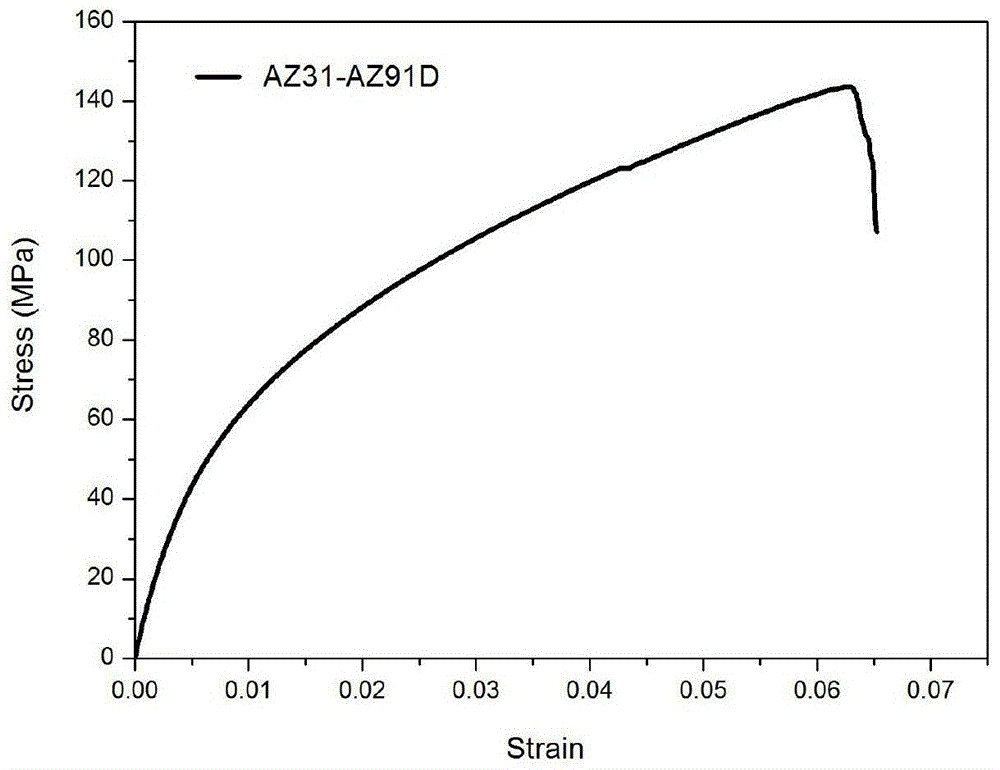

[0024] Example 1: AZ31 / AZ91D Composite Casting

[0025] Magnesium alloy grade and composition:

[0026] AZ91D magnesium alloy, its mass fraction: Al8.5~9.5%, Zn0.45~0.90%, Mn0.17~0.40%, Si≤0.05%, Cu≤0.025%, Ni≤0.001%, Fe≤0.004%, others Element ≤ 0.10% and total ≤ 0.40%, the rest is Mg.

[0027] Magnesium alloy grade and composition:

[0028] AZ31 magnesium alloy, its mass fraction: Al2.5~3.1%, Zn0.82~0.90%, Mn0.30~0.50%, Si≤0.05%, Ca≤0.05%, Be≤0.10%, Fe≤0.005%, others Element ≤ 0.10% and total ≤ 0.40%, the rest is Mg.

[0029] Specific steps:

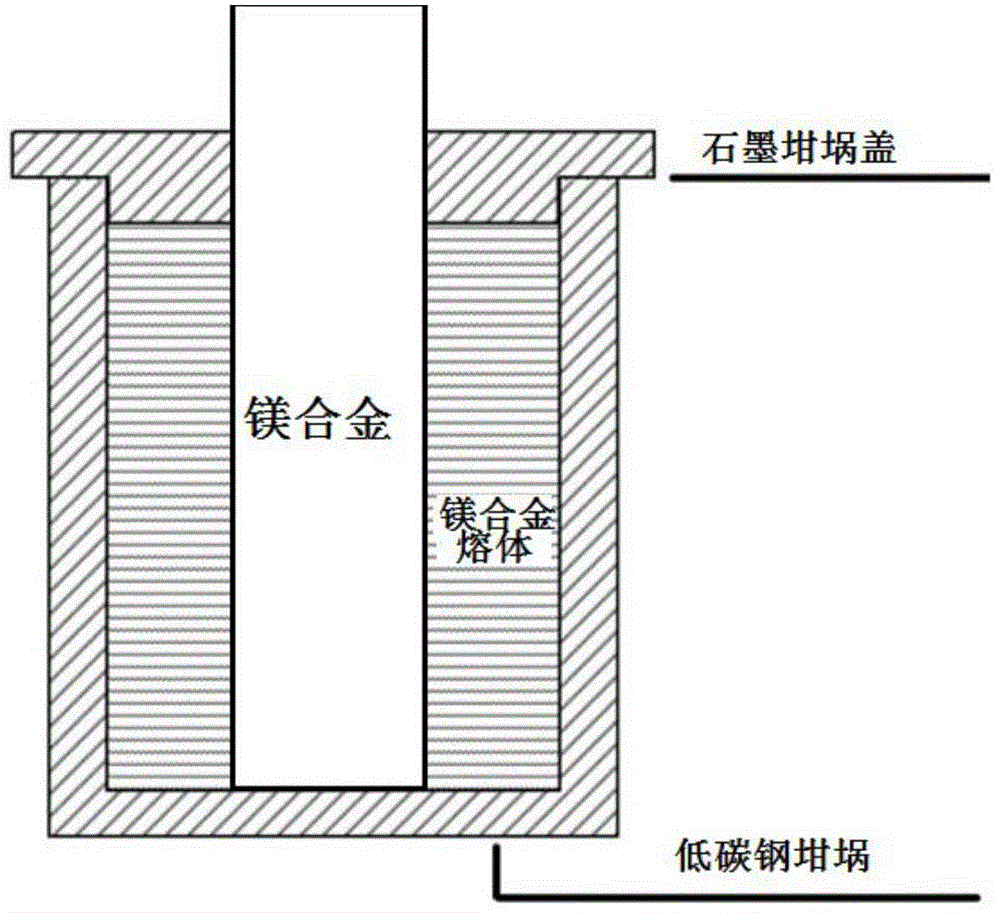

[0030] (1) Mechanically treat and chemically clean the surface of the AZ31 magnesium rod with a size of Φ30×110mm (diameter 30mm, length 110mm) obtained by machining, and remove oil stains and oxides on the surface. The mechanical treatment is to use 400#, 600#, 800#, 1000#, 1500#, 2000# sandpaper to polish in order to make the surface of the magnesium rod obtain the required roughness; the chemical cleaning is to use 5% NaOH solut...

Embodiment 2

[0035] Embodiment 2: AZ31 / AZ61 composite casting process

[0036] Magnesium alloy grade and composition:

[0037]AZ31 magnesium alloy, its mass fraction: Al2.5~3.1%, Zn0.82~0.90%, Mn0.30~0.50%, Si≤0.05%, Ca≤0.05%, Be≤0.10%, Fe≤0.005%, others Element ≤ 0.10% and total ≤ 0.40%, the rest is Mg.

[0038] Magnesium alloy grade and composition:

[0039] AZ61 magnesium alloy, its mass fraction: Al5.5~7.5%, Zn0.5~1.5%, Mn0.15~0.40%, Si≤0.10%, Fe≤0.01%, Si≤0.10%, Ni≤0.005%, other elements ≤0.10% and total ≤0.40%, the rest is Mg

[0040] Specific steps:

[0041] (1) Mechanically treat and chemically clean the surface of the AZ31 magnesium rod with a size of Φ30×110mm (diameter 30mm, length 110mm) to remove surface oil and oxides. The mechanical treatment is to grind with 400#, 600#, 800#, 1000#, 1500#, 2000# sandpaper in order to obtain the required roughness on the surface of the magnesium rod; the chemical cleaning is to use 5% NaOH solution, deionized Wash the surface of the ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com