Mixing device for molding nanometer montmorillonite and PET

A technology of nano-montmorillonite and mixing device, which is applied in the direction of chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problems of easy layering, bridging, large human error, uneven mixing, etc., and achieve difficult separation Layers and bridging, stable and reliable work, and firm bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. And the features in the embodiments can be combined with each other.

[0032] The core of the invention is to provide a mixing device for nano-montmorillonite and PET molding to realize accurate metering and precise mixing.

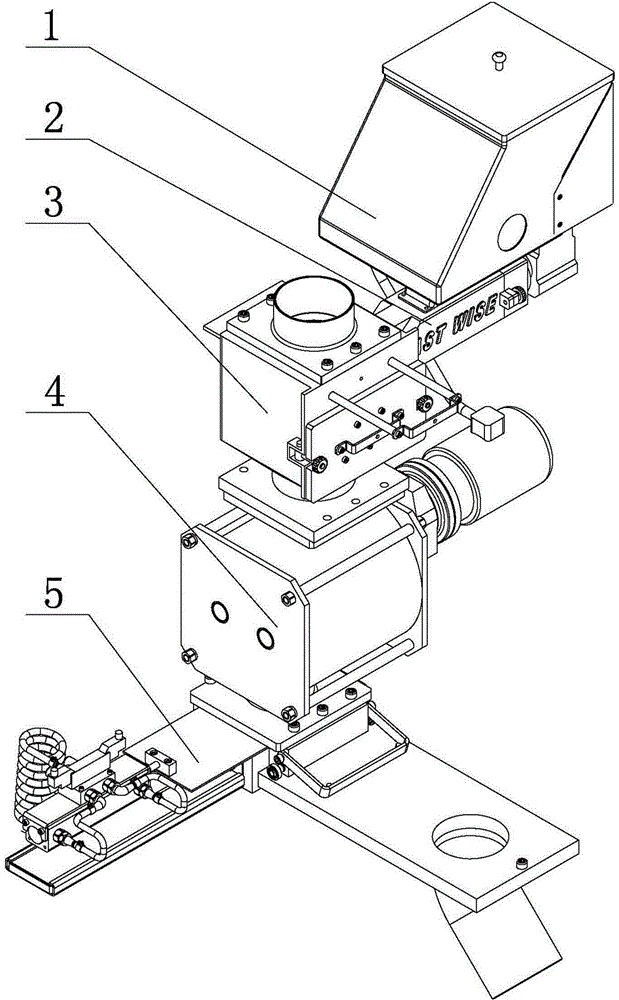

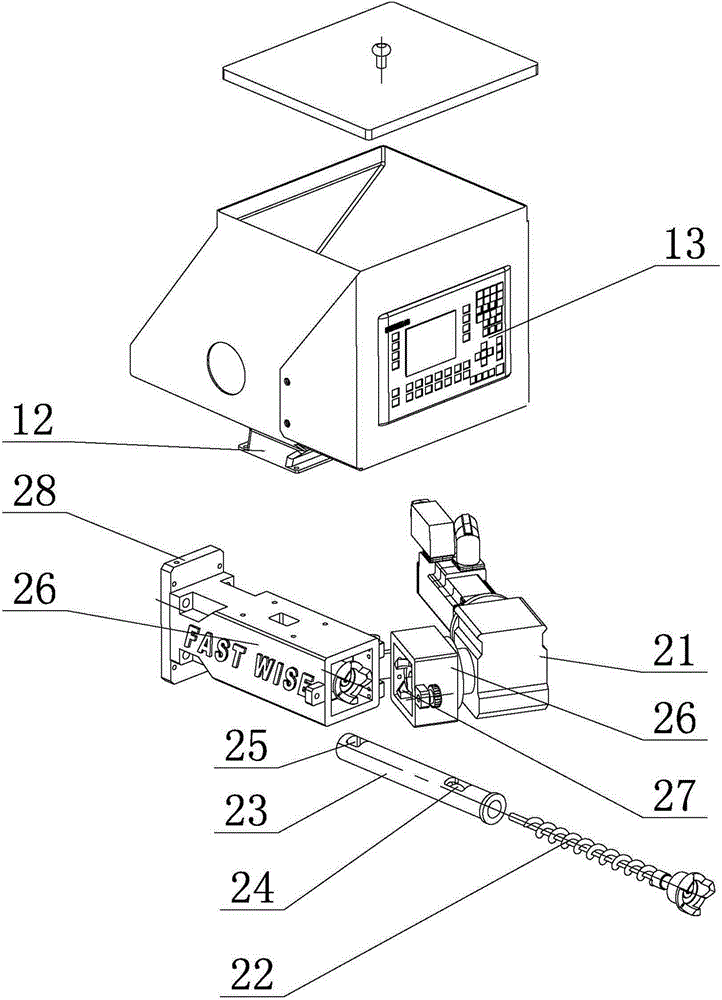

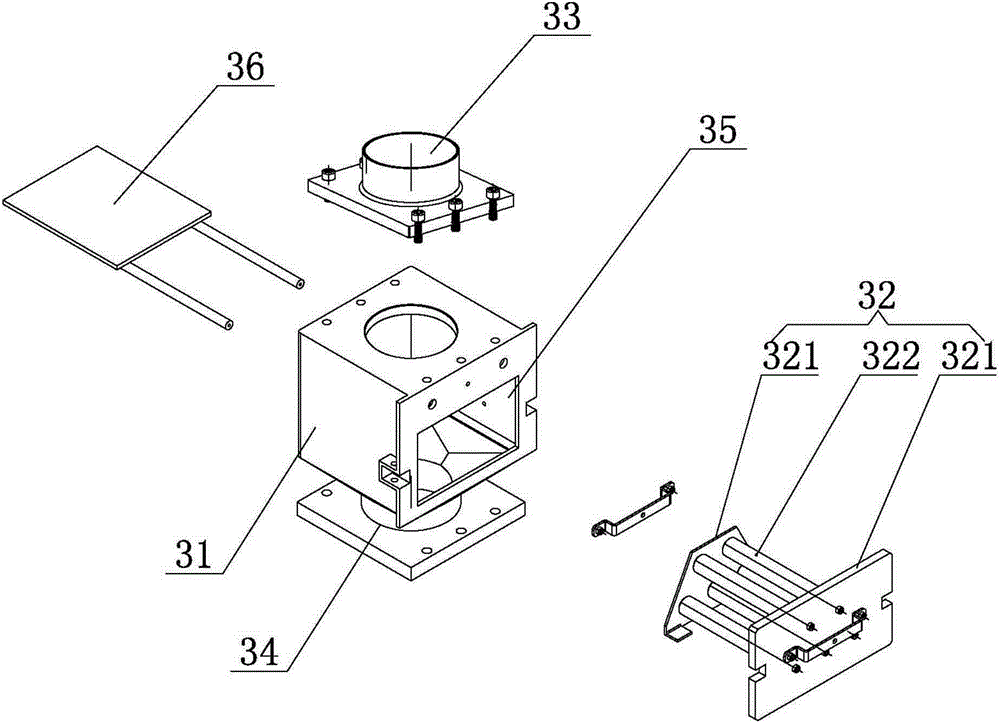

[0033] Such as Figure 1 to Figure 4 Shown, nanometer montmorillonite of the present invention and PET molding use mixing device, comprise:

[0034] Montmorillonite hopper 1, the lower part of the montmorillonite hopper 1 is provided with a discharge port 11, and the montmorillonite hopper 1 is provided with a vacuum pumping device to control the weight of powder on the hopper. The montmorillonite hopper 1 is provided with a detection port 12 for observing the accumulated amount of powder in the hoppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com