Anti-corrosion mould-proof moth-proof paint

An anti-corrosion, anti-mildew and anti-moth technology, applied in the field of coatings, can solve the problems of poor anti-corrosion and anti-mold performance, and achieve the effect of smooth and delicate hand feeling, plump and tough paint film, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

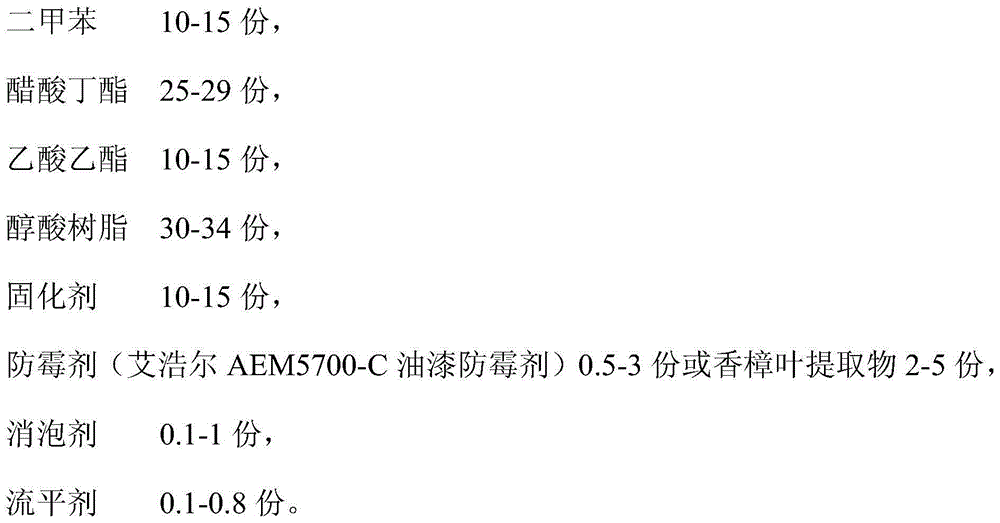

[0028] An anti-corrosion, mildew-proof and moth-proof paint is prepared by mixing the following components in parts by weight (the preparation method is an existing conventional method):

[0029]

Embodiment 2

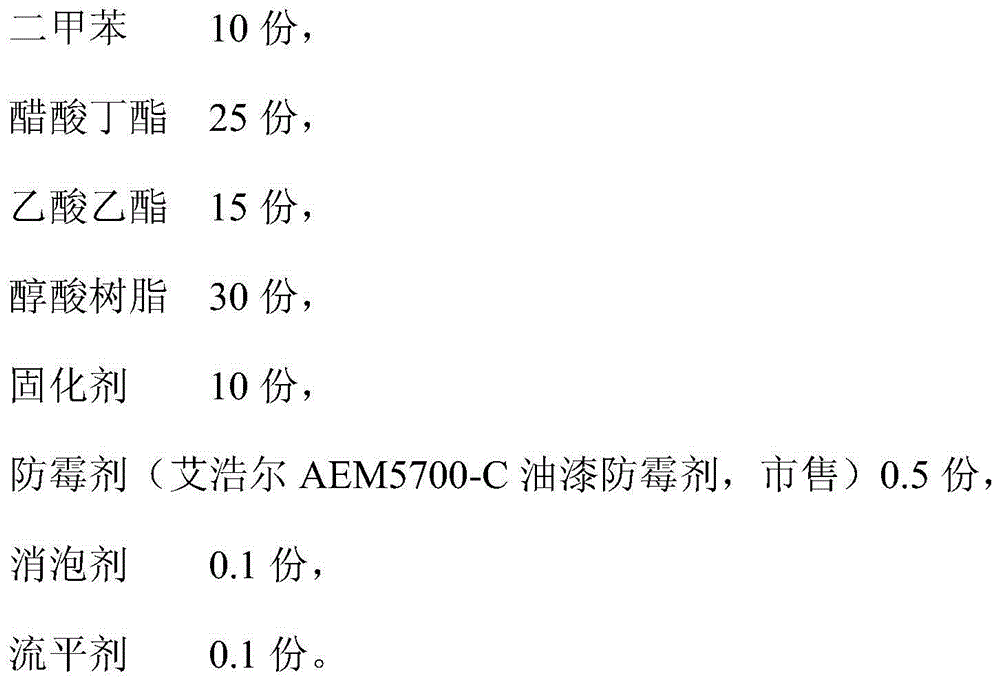

[0031] An anti-corrosion, mildew-proof and moth-proof paint is prepared by mixing the following components in parts by weight:

[0032]

[0033]

Embodiment 3

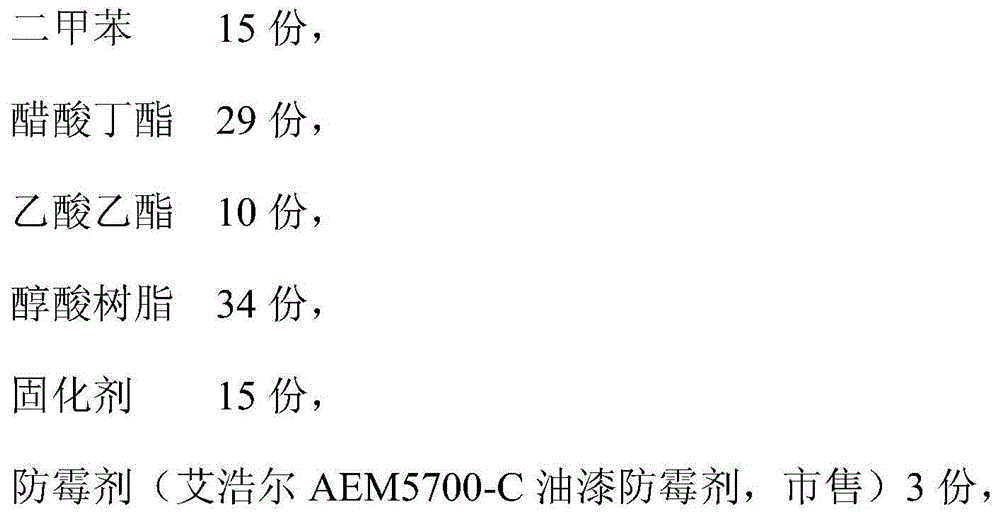

[0035] An anti-corrosion, mildew-proof and moth-proof paint is prepared by mixing the following components in parts by weight:

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com