Low-permeability reservoir microbial enhanced oil recovery composite preparation and application method thereof

A technology for microbial oil recovery and compound preparation, which is applied in the directions of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of complex and unsatisfactory microbial oil recovery construction operations, etc., and achieves low production cost, good application prospects, and good prospects. The effect of environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment provides a low-permeability oil reservoir microbial oil recovery composite preparation, which is mixed by fermentation cultures of Pseudomonas aeruginosa CGMCC1.10452 and two kinds of Bacillus subtilis CGMCC1.2172 and CGMCC1.2166, according to the volume ratio 4:3:3 mixed preparation, and the total number of microbial colonies in the composite preparation is greater than 9×1011CFU / ml.

[0030] The preparation method of the above-mentioned low-permeability oil reservoir microbial oil recovery composite preparation includes the following steps: first activate Pseudomonas aeruginosa CGMCC1.10452, Bacillus subtilis CGMCC1.2172, and Bacillus subtilis CGMCC1.2166 in LB solid medium; The fermentation liquid medium corresponding to the bacterial strain was inoculated and cultured for 48 hours, and then the three bacterial solutions were combined to prepare a microbial oil recovery composite preparation.

[0031] The formula of LB solid medium is: tryptone 10g / L,...

Embodiment 2

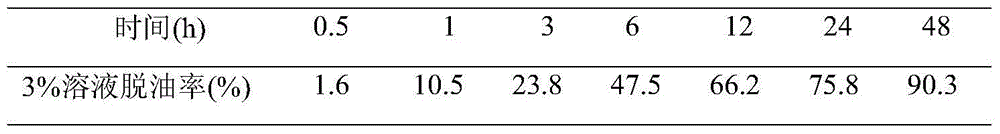

[0049] Deoiling Effect of Microbial Oil Recovery Compound Preparation on Crude Oil

[0050]Triassic Chang 6 oil reservoir Wangyao block crude oil and quartz sand were mixed at a volume ratio of 1:1, and aged at 37°C for 1 week. Take 20g of dried quartz sand with oil, add 50ml of 3% microbial oil recovery compound preparation, blank control Wangyao block oilfield formation water, and simulate formation temperature at 35°C for constant temperature cultivation for 48h. After 0.5, 1, 3, 6, 12, 24, and 48 hours, take out and measure the crude oil floating on the liquid surface, and test the deoiling efficiency of the microbial oil recovery composite preparation. The experimental results are shown in Table 1. With the microbial oil recovery With the prolongation of the action time of the compound preparation, the oil layer on the liquid surface in the beaker where the microbial oil recovery compound preparation is added gradually becomes thicker, and the bottom quartz sand gradually...

Embodiment 3

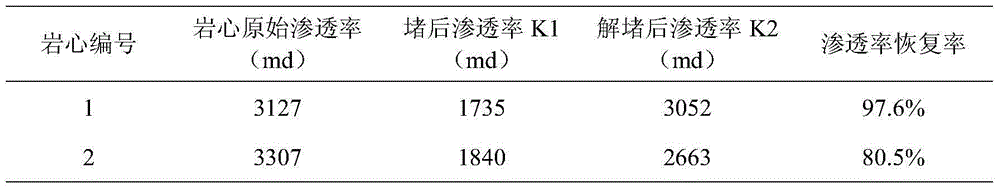

[0054] Experiment of removing plugging and restoring rock core permeability with microbial oil recovery compound preparation

[0055] Using 3% microbial oil recovery compound preparation to carry out the plugging removal experiment, record the change of permeability before and after, and evaluate the plugging removal recovery efficiency of the microbial oil recovery compound preparation. Take the artificial core, connect the normal phase with brine, and measure the permeability k0 of the brine; connect the normal phase with crude oil mixed with sand to form a blockage; flow the reverse phase with brine, measure the permeability k1 of the brine before removing the plugging; Soak for 24 hours to remove the blockage; connect the brine in the normal phase, measure the permeability k2 of the brine after the blockage is removed, and see Table 2 for the experimental results. The results show that the recovery rate of 3% microbial oil recovery composite preparation can reach 97.6% and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com