Steel plate spinning multi-wedge motor belt wheel and spinning method thereof

A spinning machine, steel plate technology, applied in the direction of belt/chain/gear, mechanical equipment, components with teeth, etc., can solve the problems of unsatisfactory groove surface finish, heavy pulley weight, large material consumption, etc., to achieve parts weight Reduced, improved material utilization, good finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

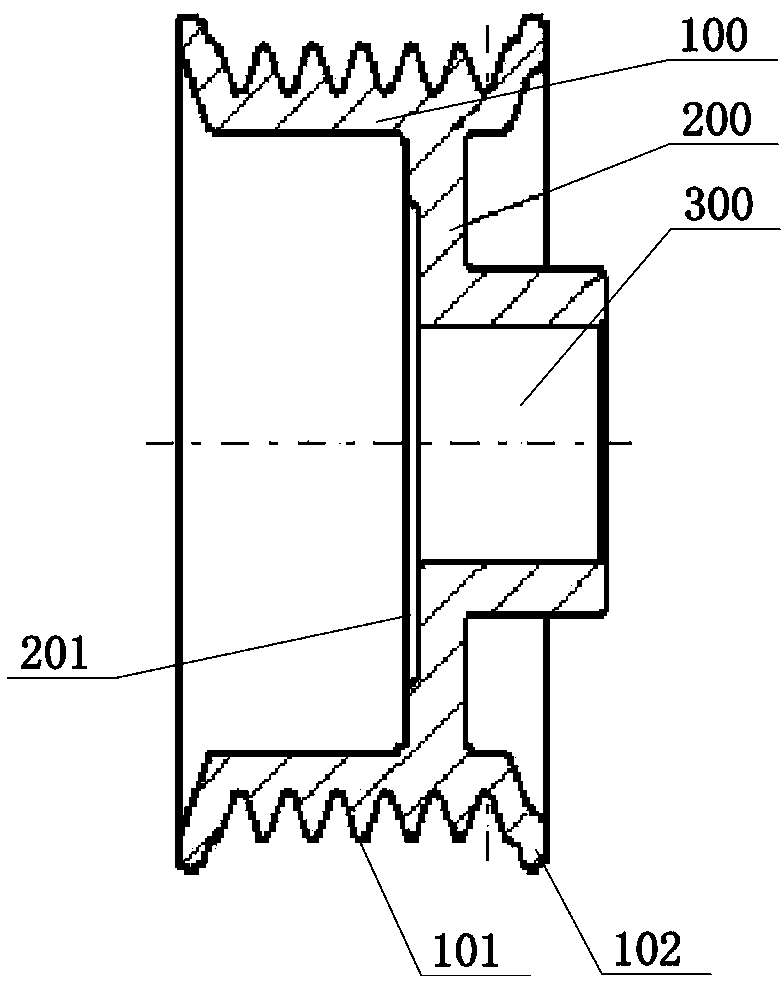

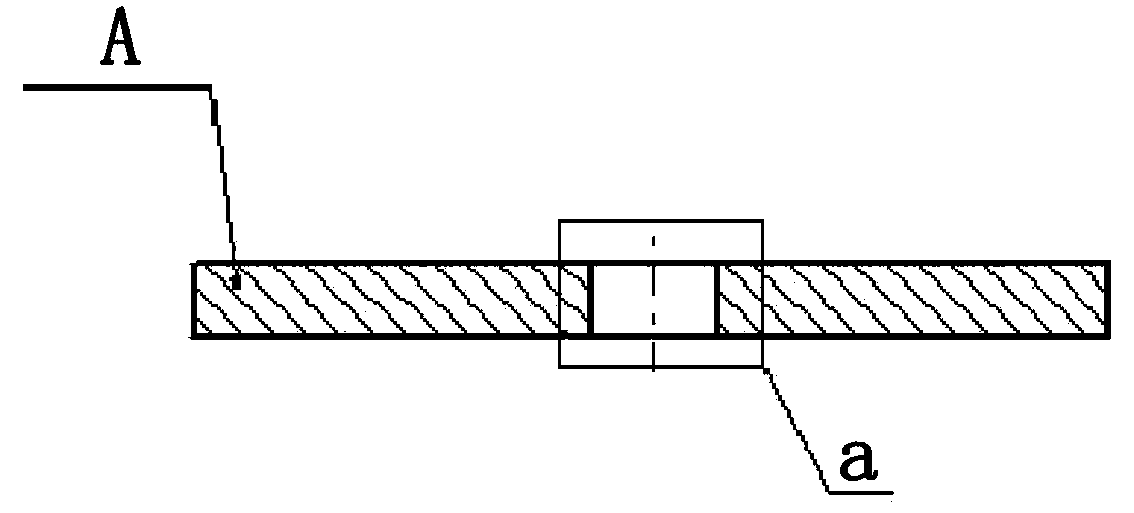

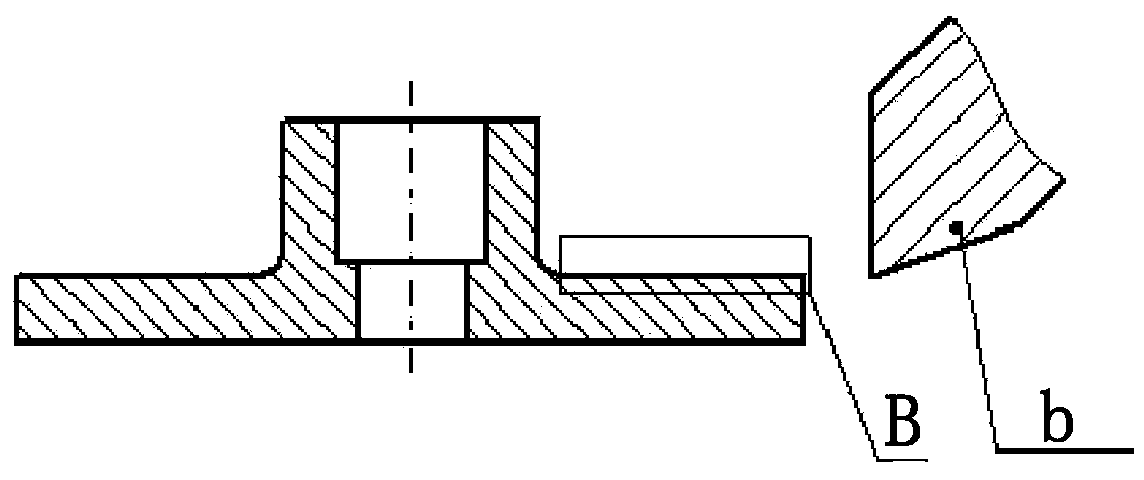

[0030] The accompanying drawing is a schematic sectional view of a spinning poly-V-belt pulley of the present invention.

[0031] A steel plate spinning multi-ribbed motor pulley, comprising a wheel surface 100, spokes 200, and a central inner hole 300. The wheel face 100 and the spokes 200 are a spinning integral structure. The parts are made of 6mm sheet metal, and are formed through blanking, spinning bosses, spinning V-shaped grooves, punching and other main processes. The wheel surface 100 and the spokes 200 are connected as one, which changes the traditional welding connection method. , to ensure the strength of the pulley, and the wheel surface 100 and the spokes 200 are center-symmetric structures, the tooth surface finish is good, the surface structure is dense and wear-resistant, the service life of the pulley is improved, and the product qualifica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com