B-cemented semiconductor-heating temperature and humidity self-compensation integrated gas sensor

A gas sensor, integrated sensor technology, applied in instruments, scientific instruments, measuring devices, etc., can solve the problems of working temperature changing with the environment, single gas parameters, large volume, etc., to achieve easy control of heating speed, high energy utilization, Highly integrated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

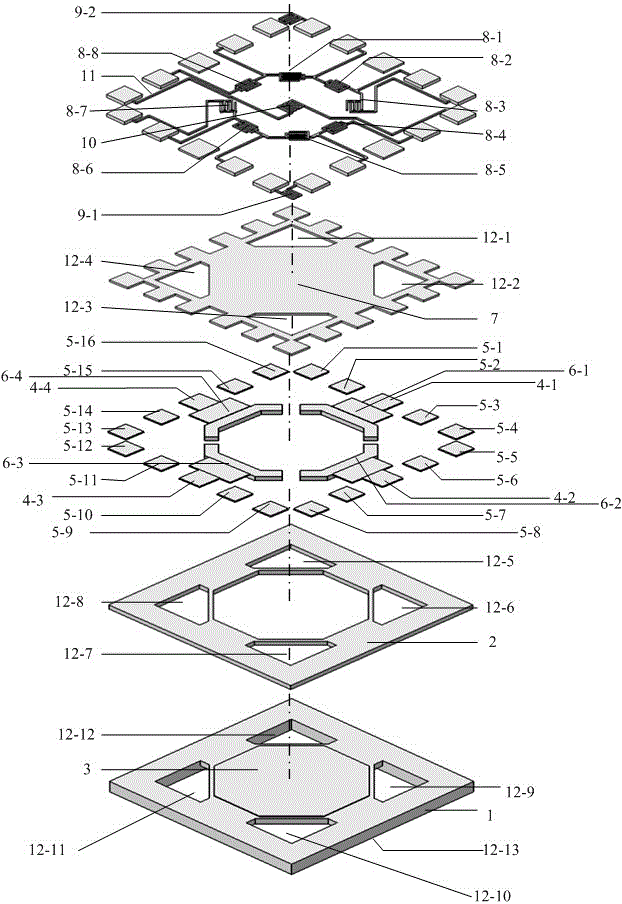

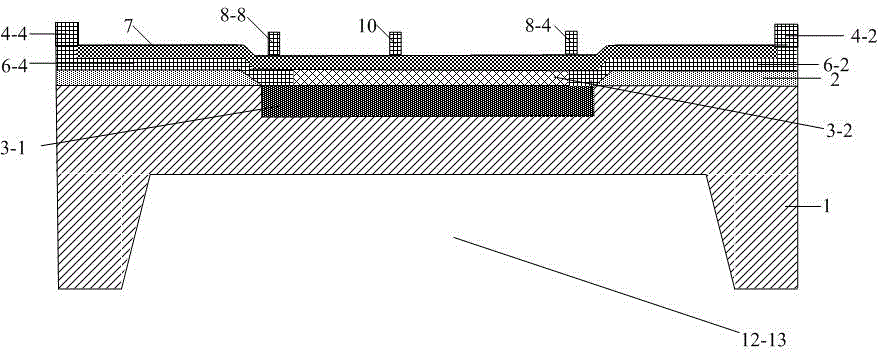

[0021] Specific implementation mode 1: The pad (4) of the semiconductor heating body in this sensor is composed of four parts (4-1), (4-2), (4-3), and (4-4). The semiconductor heating electrode (6) Composed of four parts (6-1), (6-2), (6-3), and (6-4), the pad of the semiconductor heating body (4-1) and the semiconductor heating electrode (6- 1) connected, (4-2) connected with (6-2), (4-3) connected with (6-3), (4-4) connected with (6-4), semiconductor heating electrode (6) connected with The permeable B semiconductor heating body (3) is connected, and the gas sensor unit pad (5) is composed of (5-1), (5-2), (5-3), (5-4), (5-5), ( 5-6), (5-7), (5-8), (5-9), (5-10), (5-11), (5-12), (5-13), (5- 14), (5-15) and (5-16) sixteen sensor unit pads, the gas sensor unit (8) consists of (8-1), (8-2), (8-3), (8 -4), (8-5), (8-6), (8-7), (8-8) are composed of eight gas sensor units, and the ambient temperature and humidity sensor (9) is composed of the ambient humidity sensor unit (9-1 ...

specific Embodiment approach 2

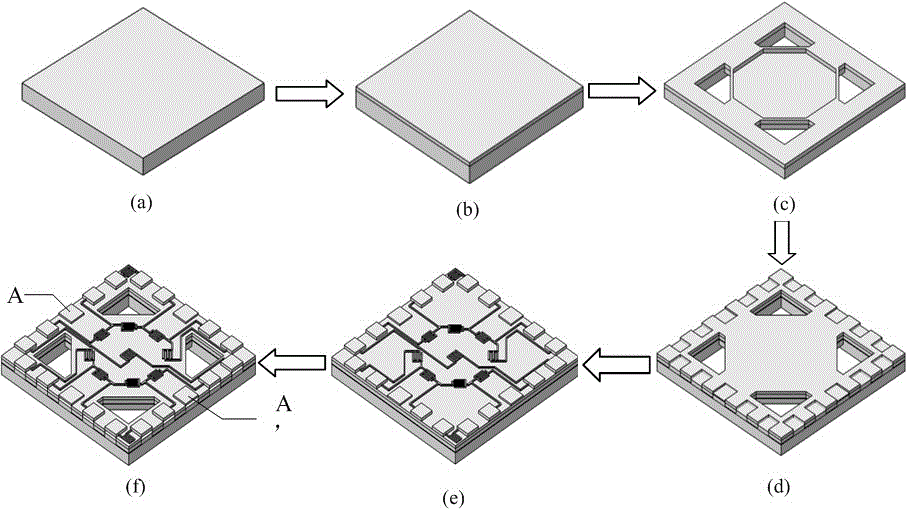

[0022] Specific implementation mode two: combination figure 2 and Figure 4 To describe this embodiment, starting from the top view surface of the sensor, use hydrochloric acid, hydrofluoric acid, and EPW etchant in sequence to etch away unnecessary alumina, silicon dioxide, and silicon to form a cantilever beam structure.

specific Embodiment approach 3

[0023] Specific implementation mode three: combination figure 2 and image 3 Describe this embodiment, the B-infiltrated semiconductor heating body (3), the B-infiltrated semiconductor heating body pad (4), the gas sensor unit pad (5), the semiconductor heating electrode (6), and the aluminum oxide insulating layer (7) of the sensor ), the gas sensor unit (8), the heating body temperature sensor unit (10) and the groove (12) all have a symmetrical structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com