soft switching dc‑dc converter

A technology of DC-DC and converters, applied in the field of soft-switching DC-DC converters, can solve problems such as safety, reliability reduction, high rated voltage, and system cost increase, so as to improve safety and reliability, reduce The effect of reducing the maximum voltage and reducing the switching loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

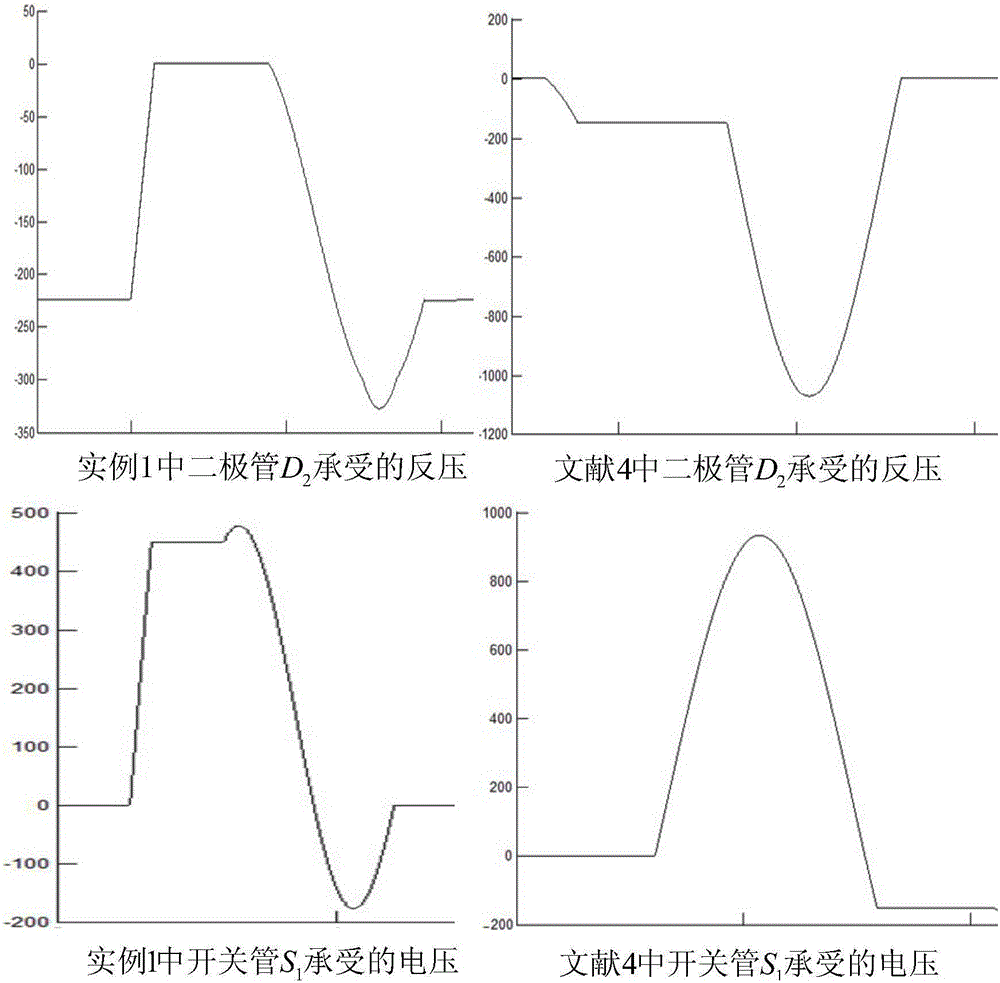

[0041] The topological diagram of embodiment 1 is as figure 1 mentioned. In this embodiment, the switch assembly is an anti-blocking switch tube, and a first switch tube S 1 and a diode in series, see the specific structure image 3 301 in.

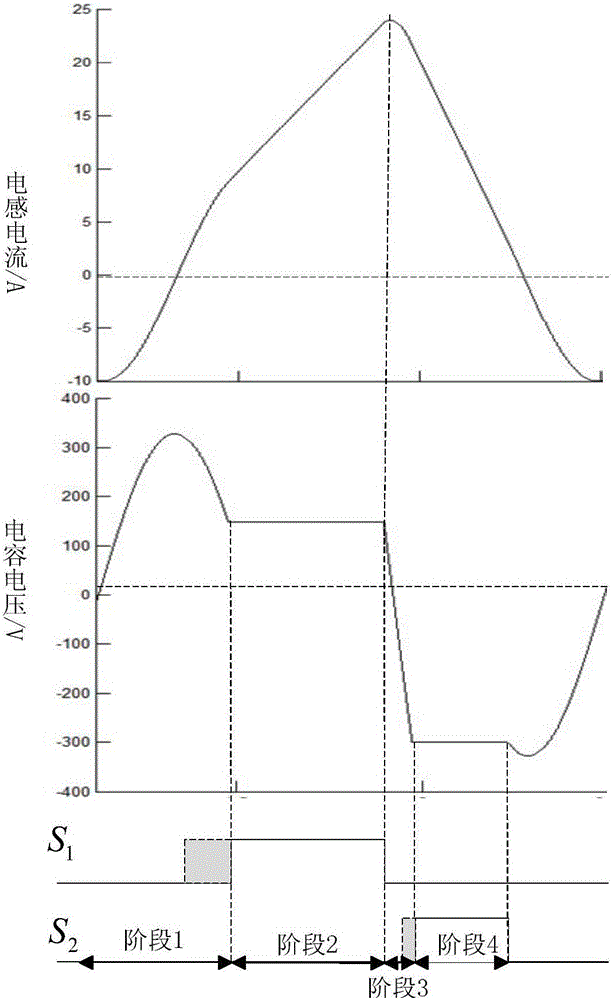

[0042] The working process is mainly divided into four stages. The commutation process is as follows: Figure 4 shown.

[0043] In order to explain the working process of the converter more clearly, let the input voltage be U in , the output voltage is U o , when the voltage on the upper side of the capacitor voltage is greater than the voltage on the lower side, it is a positive voltage, and the downward flow of the inductor current is a positive direction.

[0044] Working stage one: the first switching tube S in this process 1 , the second switch tube S 2 All are in the off state, after the end of the last working stage, the resonant inductance L 2 and resonant capacitor C 2 start to resonate as Figure 4 As shown in (a), w...

Embodiment 2

[0052] The topological diagram of embodiment 2 is as figure 2 mentioned. In this embodiment, the switch assembly is an anti-parallel switch tube, consisting of a first switch tube S 1 and a diode, the diode and the first switch S 1 It is connected in anti-parallel mode, see the specific structure image 3 302 in.

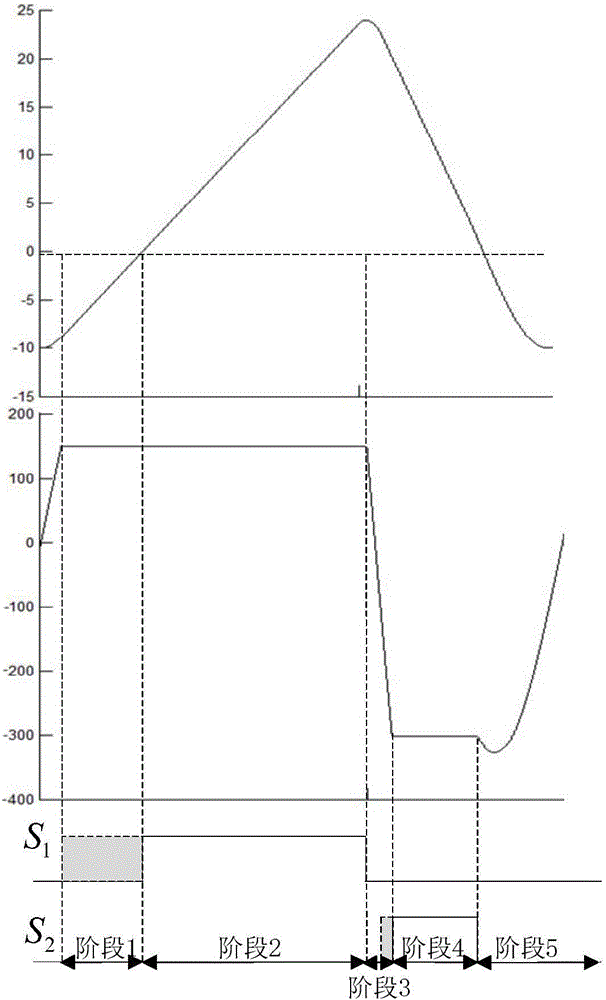

[0053] The working process of the soft-switching DC-DC converter in this embodiment is mainly divided into five stages. The commutation process is as follows: Figure 8 shown.

[0054] In order to explain the working process of the converter more clearly, we set the input voltage as U in , the output voltage is U o , when the voltage on the upper side of the capacitor voltage is greater than the voltage on the lower side, it is a positive voltage, and the downward flow of the inductor current is a positive direction.

[0055] Working stage one: the first switching tube S in this process 1 , the second switch tube S 2 All are in the off state, after the end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com