A kind of preparation method of nanometer drug-loaded fiber membrane with temperature-sensitive drug release performance

A nano-drug-loading and temperature-sensitive technology, which is applied in the field of preparation of nano-drug-loaded fiber membranes, can solve the problems of low drug effectiveness, frequent medication, and toxic and side effects, and achieve convenient drug administration, easy portability, and simple preparation methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

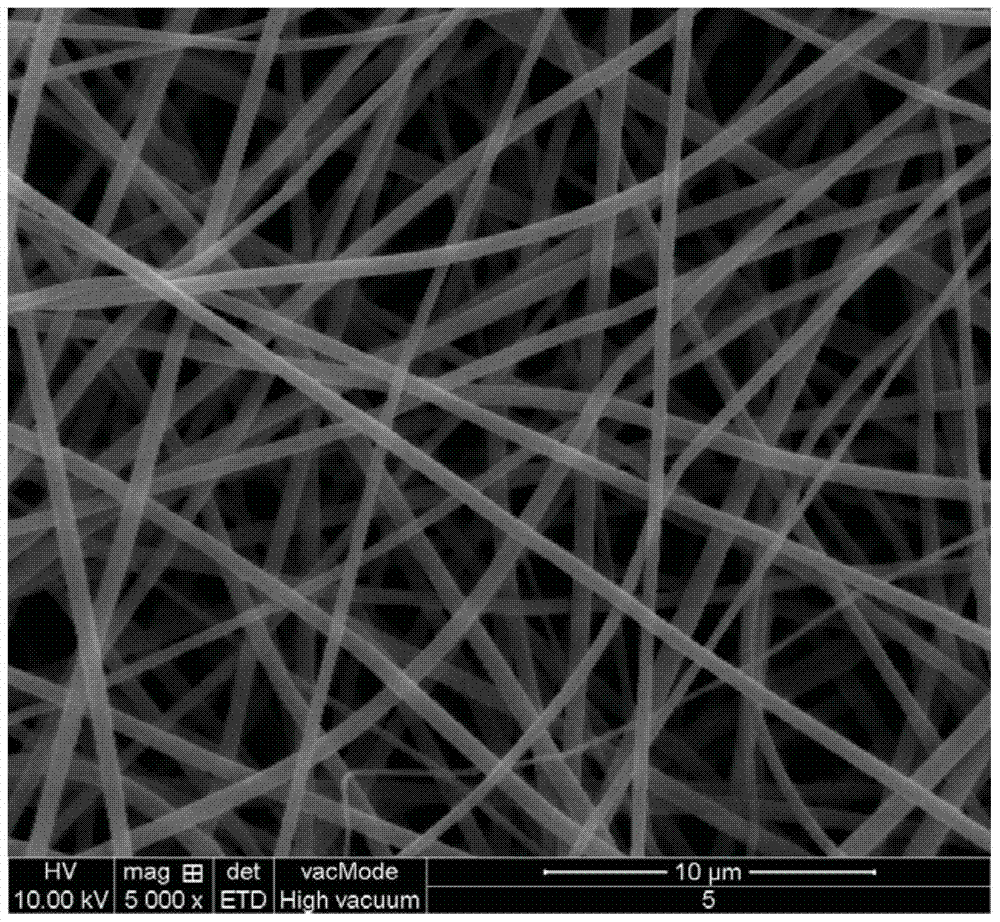

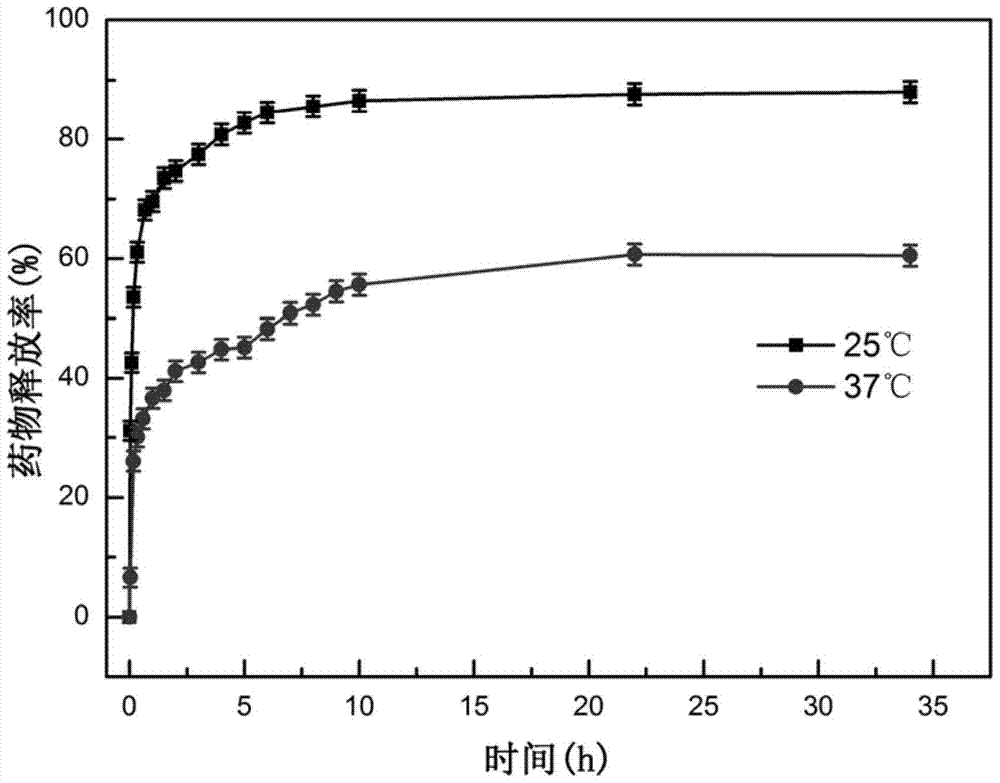

[0025] (1) Preparation of spinning stock solution: Weigh 0.167gPNIPAAm and 0.333gEC respectively with an electronic analytical balance, dissolve the mixture of the two in 2 milliliters of absolute ethanol, then add 0.125gKET to the solution obtained, and bring the final gained solution to room temperature Under magnetic stirring for 24-48h, until completely dissolved (the mass ratio of PNIPAAm to EC in the solution is 1:2).

[0026] (2) The electrospinning solution obtained above is spun on an electrospinning device, using a No. 9 needle, wherein the voltage is 13 kV, the advancing speed of the syringe is 0.5 ml / hour, and the distance between the receiving plate and the spinneret is 15 cm. , the ambient temperature is (25±1)°C, and the ambient humidity is 57±3%. Receive it with aluminum foil, and after the electrospinning of the spinning liquid in the syringe is completed, remove the fiber membrane and dry it under vacuum at room temperature for 24 hours.

Embodiment 2

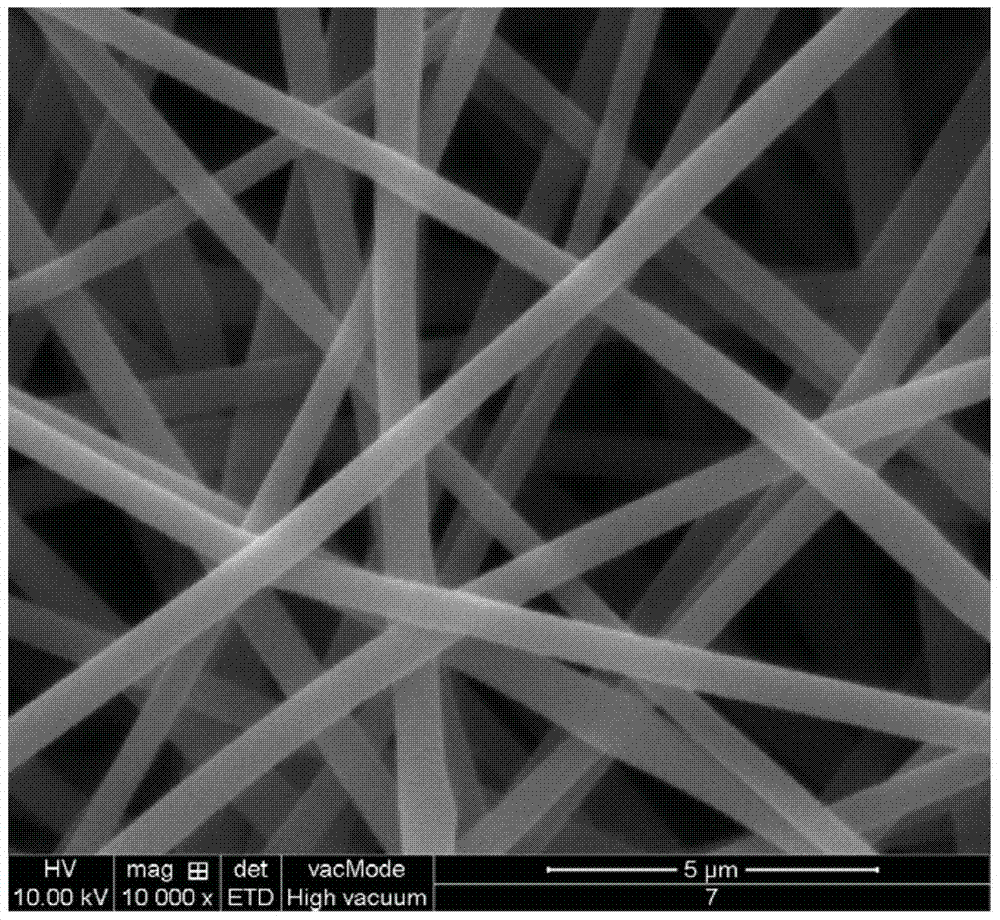

[0028] (1) Preparation of spinning stock solution: take by weighing 0.125gPNIPAAm and 0.375gEC respectively with an electronic analytical balance, dissolve the mixture of the two in 2 milliliters of absolute ethanol, then add 0.125gKET to the solution obtained, and put the final gained solution at room temperature Under magnetic stirring for 24-48h, until completely dissolved (the mass ratio of PNIPAAm to EC in the solution is 1:3).

[0029] (2) The electrospinning solution obtained above is spun on an electrospinning device, using a No. 9 needle, wherein the voltage is 13 kV, the advancing speed of the syringe is 0.5 ml / hour, and the distance between the receiving plate and the spinneret is 15 cm. , the ambient temperature is (25±1)°C, and the ambient humidity is 57±3%. Receive it with aluminum foil, and after the electrospinning of the spinning liquid in the syringe is completed, remove the fiber membrane and dry it under vacuum at room temperature for 24 hours.

Embodiment 3

[0031] (1) Preparation of spinning stock solution: Weigh 0.100gPNIPAAm and 0.400gEC respectively with an electronic analytical balance, dissolve the mixture of the two in 2 milliliters of absolute ethanol, then add 0.125gKET to the solution obtained, and place the final gained solution at room temperature Under magnetic stirring for 24-48h, until completely dissolved (the mass ratio of PNIPAAm to EC in the solution is 1:4).

[0032] (2) The electrospinning solution obtained above is spun on an electrospinning device, using a No. 9 needle, wherein the voltage is 13 kV, the advancing speed of the syringe is 0.5 ml / hour, and the distance between the receiving plate and the spinneret is 15 cm. , the ambient temperature is (25±1)°C, and the ambient humidity is 57±3%. Receive it with aluminum foil, and after the electrospinning of the spinning liquid in the syringe is completed, remove the fiber membrane and dry it under vacuum at room temperature for 24 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com