Nano-analgesic agent and preparation method thereof

An analgesic and nanotechnology, applied in the field of nano-analgesics and their preparation, can solve the problems of restricting clinical application, prone to gastrointestinal adverse reactions, etc., and achieve the effects of low cost, convenient administration, and prolonged drug effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Preparation of spinning dope: Suspend 8.75 g of ketoprofen in 100 mL of methanol, and gradually add 35 g of polyvinylpyrrolidone PVP K30 at 40°C and rapid stirring (50 rpm) to prepare the spinning dope;

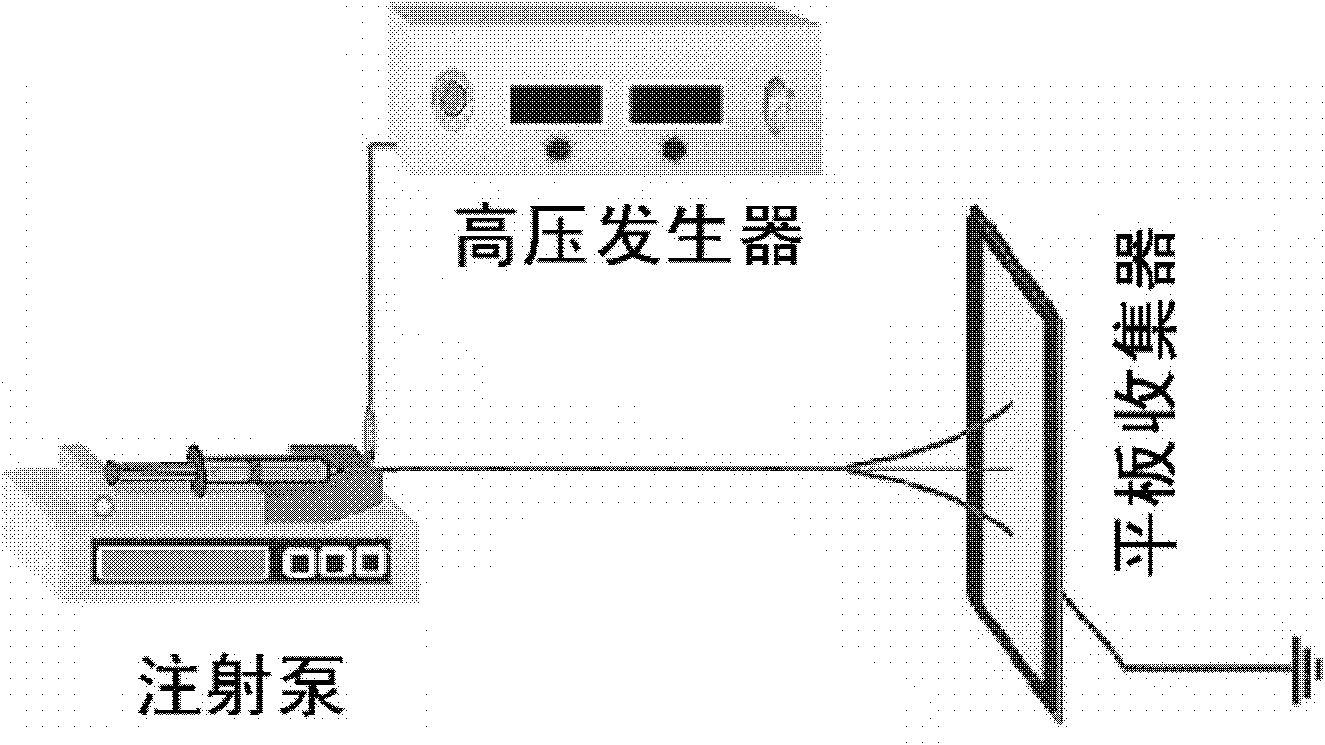

[0033] (2) Preparation of ketoprofen / polyvinylpyrrolidone nanofiber membrane: pour the prepared spinning stock solution into the solution reservoir (5mL syringe), use a flattened No. 9 injection needle as the capillary for the jet stream, and connect the high pressure For the positive electrode of the power supply, the aluminum foil fiber receiving plate with a glass slide is used as the negative electrode, and the fiber is spun for 10 minutes for observation by a polarizing microscope, and then the aluminum foil receiving plate is used to connect the negative electrode and receive the fiber; Electrospinning process Condition: Flow rate is 2mL·h -1 , The distance between the receiving plate and the spinneret is 15cm, the voltage is 12kV, the ambient temperature is (20±...

Embodiment 2

[0037] (1) Preparation of spinning dope: Suspend 3 g of ketoprofen in 100 mL of ethanol, and gradually add 12 g of ethyl cellulose during the process of heating to 48° C. and stirring to prepare the spinning dope;

[0038] (2) Preparation of ketoprofen / ethyl cellulose nanofiber membrane: pour the above-mentioned prepared spinning stock solution into the solution reservoir (5mL syringe), use a flattened 9-gauge injection needle as the capillary for the jet stream, and connect The positive electrode of the high-voltage power supply first uses the aluminum foil fiber receiving plate with a glass slide as the negative electrode, and receives the spinning fiber for 10 minutes for observation by the polarizing microscope, and then uses the aluminum foil receiving plate to connect the negative electrode and accept the fiber; Process conditions: flow rate is 1.5mL·h -1 , The distance between the receiving plate and the spinneret is 10cm, the voltage is 15kV, the ambient temperature is (20...

Embodiment 3

[0041] (1) Preparation of spinning stock solution: Suspend 8.75 g of ketoprofen in 100 mL of methanol, and gradually add 35 g of polyvinylpyrrolidone PVP K30 to prepare ketoprofen during heating to 55°C and rapid stirring (50 rpm). Polyvinylpyrrolidone spinning dope;

[0042] Suspend 3 g of ketoprofen in 100 mL of ethanol, and gradually add 12 g of ethyl cellulose during heating at 45°C and rapid stirring (50 rpm) to prepare the ketoprofen / ethyl cellulose spinning stock solution;

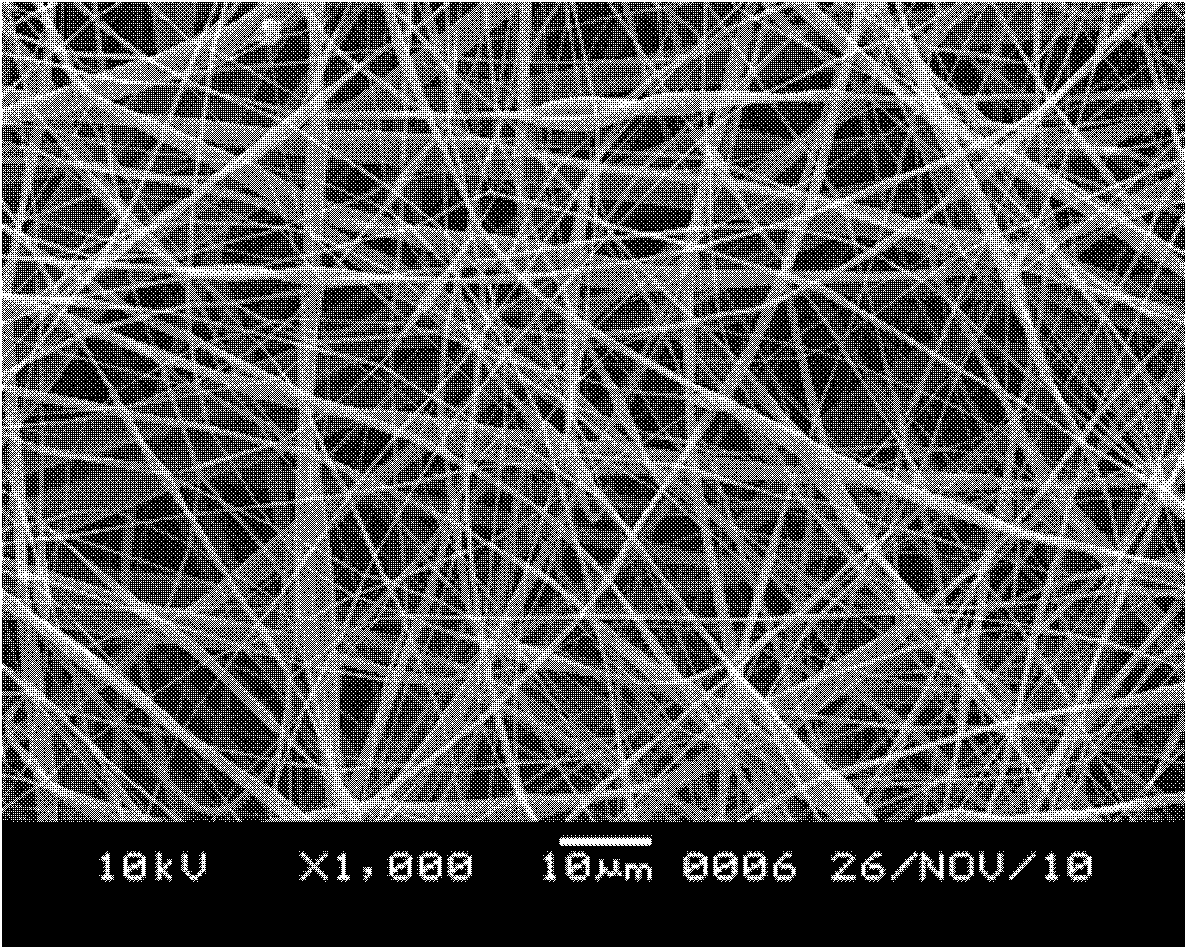

[0043] (2) Preparation of ketoprofen / polyvinylpyrrolidone / ethylcellulose nanofiber membrane: the first layer of electrospinning: pour the ketoprofen / polyvinylpyrrolidone spinning stock solution obtained above into solution reservoir No. 1 (5mL syringe In ), a flattened No. 9 injection needle is used as a capillary for jetting a trickle, connected to the positive electrode of a high-voltage power supply, and an aluminum foil receiving plate is used to connect the negative electrode and receive fibers; the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com