Three-in-one plate exchange type refrigeration dryer and work method

A three-in-one, cold dryer technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problem that it is difficult to adapt to the customer's use environment, the shell-and-tube heat exchanger has a large volume, and the heat transfer efficiency is not very high Advanced problems, to achieve the effect of equipment volume reduction, volume reduction, and material cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

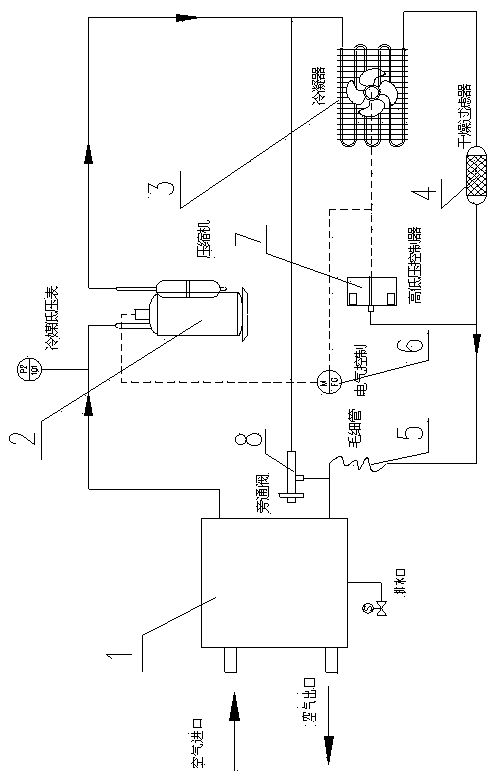

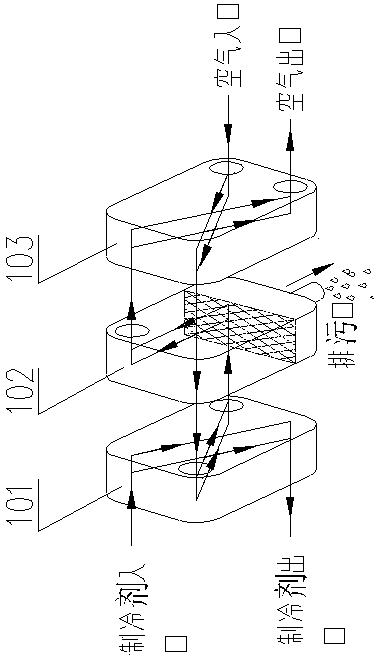

[0010] Embodiment 1: with reference to attached figure 1 and 2 . A three-in-one plate exchange type cold dryer, one end of the compressed air enters the three-in-one stainless steel plate heat exchanger 1, after heat exchange and cooling, it passes through the plate exchange built-in wire mesh to separate and remove water, and the outlet is connected to the customer's back-end pipeline; One end three-in-one stainless steel plate heat exchanger 1 Refrigeration system evaporator 101 outlet is connected to the inlet of refrigeration compressor 2 through pipes, the outlet of refrigeration compressor 2 is connected to the inlet of condenser 3 through pipes, the outlet of condenser 3 is connected to the dry filter through pipes 4 is connected to the inlet, and the outlet of drier filter 4 is connected to the inlet of capillary 5 through pipelines, and the other is connected to the high and low pressure controller 7, the outlet of capillary 5 is connected to the inlet of evaporator ...

Embodiment 2

[0011] Example 2: On the basis of Example 1, the working method of the three-in-one plate exchange type cold dryer, (1) Gas system, heat exchange system and gas-water separation system: 1. Hot and humid compressed gas enters the cold dryer , firstly in the pre-cooler, it exchanges heat with the low-temperature and dry compressed gas, so that the temperature drops, and some of the water condenses into liquid, and then enters the evaporator; the low-temperature gas is heated up in the pre-cooler, avoiding the The gas temperature is too low to cause condensation on the outer wall of the downstream gas pipeline; 2. The pre-cooled compressed gas enters the evaporator and is forcibly cooled to 2-10°C by the Freon refrigeration system to further condense the water vapor in it, and then enters In the gas-liquid separator; 3. After being separated by the gas-liquid separator, the liquid water is automatically discharged through the floating ball drainer; 4. The dryness of the gas after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com