Automatic welding method based on 3D model and machine vision

A three-dimensional model and automatic welding technology, which is applied to welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of not having a wide range of automatic welding seam positions, not having real-time adjustment control, and being unable to adapt to thermal deformation, etc., to achieve Realize the effects of welding operation, fast positioning speed, and overcoming errors in processing and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

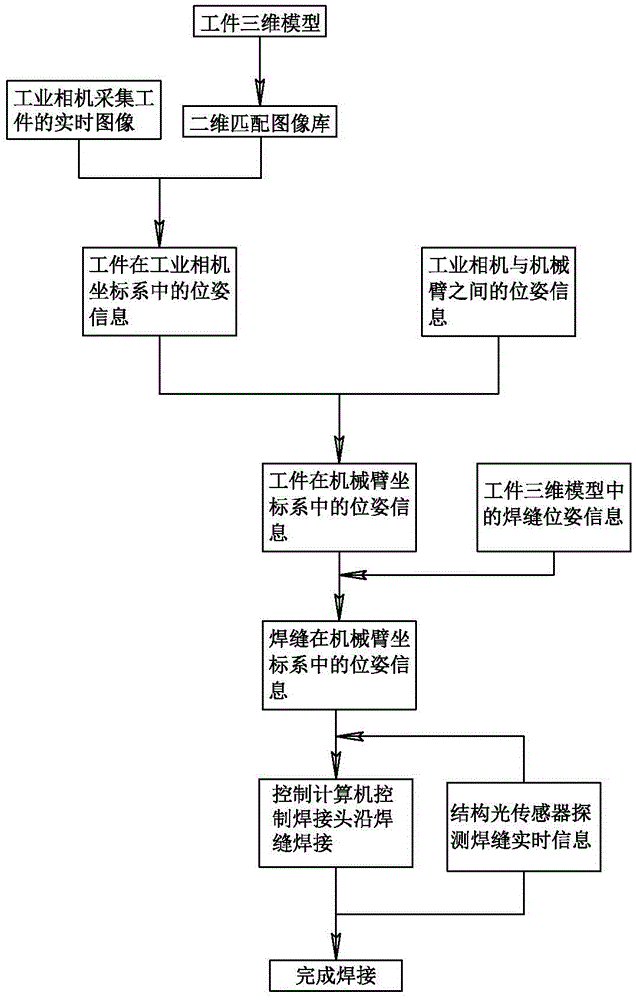

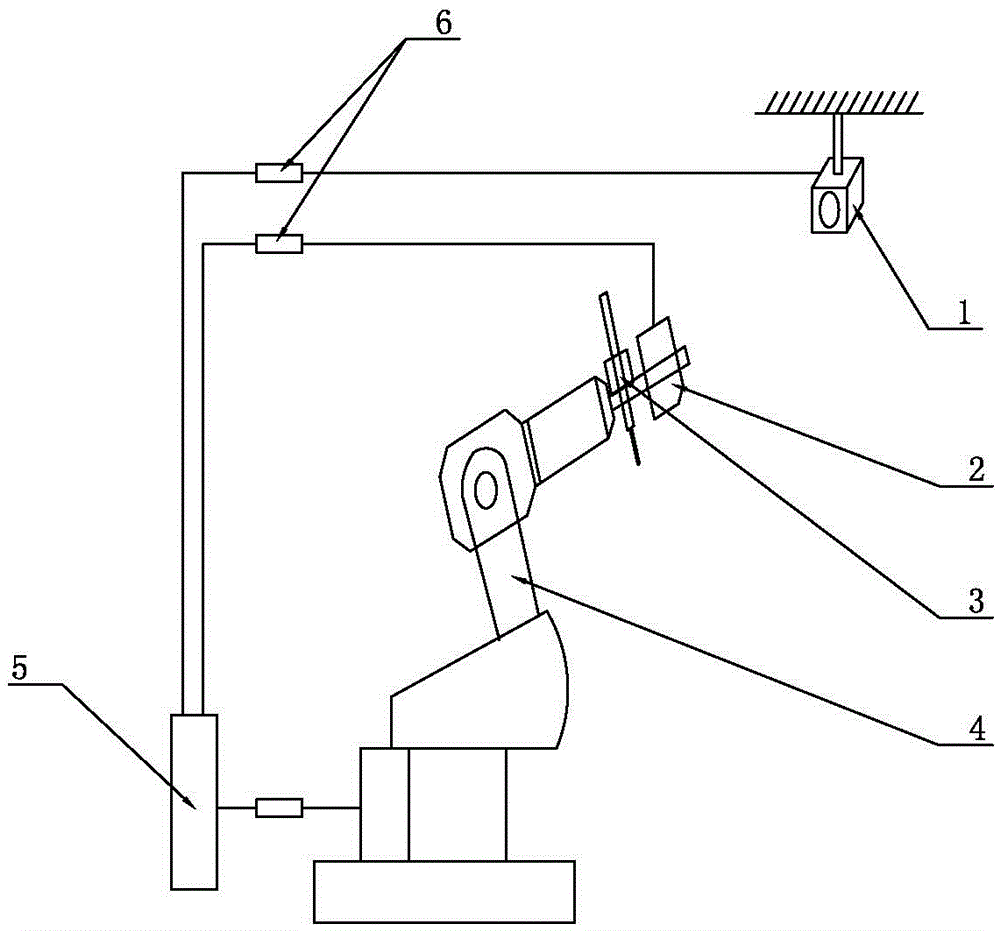

[0022] Such as figure 2 As shown, it is an automatic welding device based on a three-dimensional model and machine vision. Its structure mainly includes a mechanical arm 4 with six degrees of freedom. The six degrees of freedom are linear motions in the directions of X, Y and Z axes. , and rotation around the X, Y, and Z axes; the mechanical arm 4 holds the welding torch 3, and the end of the mechanical arm 4 is provided with a structured light sensor 2. The device also includes an industrial camera 1, and the workpiece collected by the industrial camera 1 The image signal is transmitted to the control computer 5, and the control computer 5 compares the plane figure converted from the three-dimensional model of the workpiece with the image signal collected by the industrial camera to obtain the pose information of the workpiece in the coordinate system of the industrial camera, and then according to the pose information Determine the position and orientation information of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com