an automatic sawing machine

A sawing machine and automatic technology, which is applied in the direction of grinding machines, grinding machine parts, grinding workpiece supports, etc., can solve the problems of threatening the safety and health of operators, dangerous hands, and difficult control of size, etc., and achieves a compact and scientific structure. , easy maintenance and low defective rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

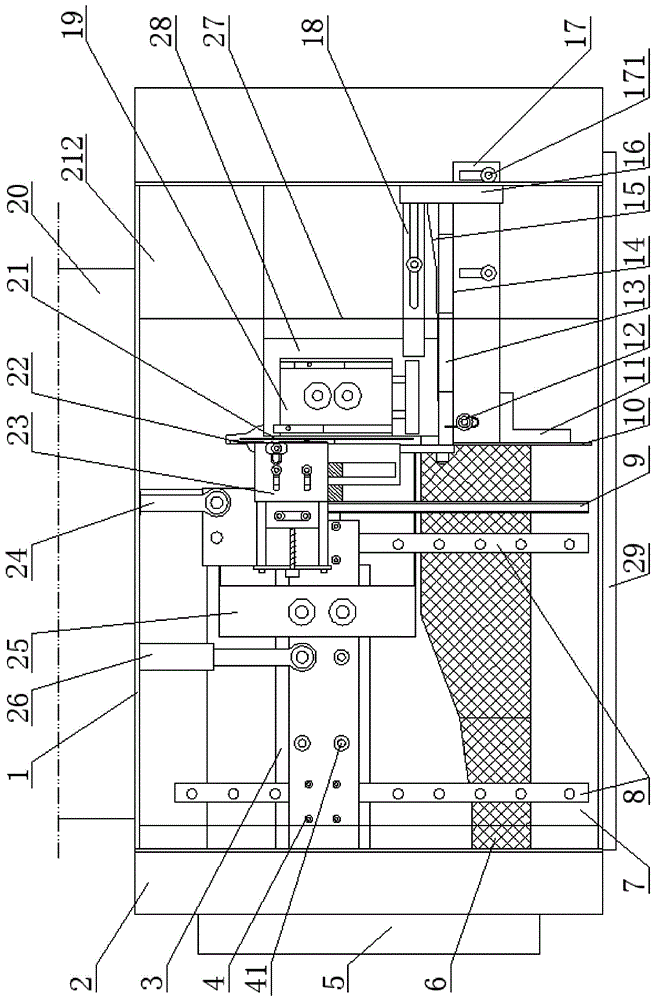

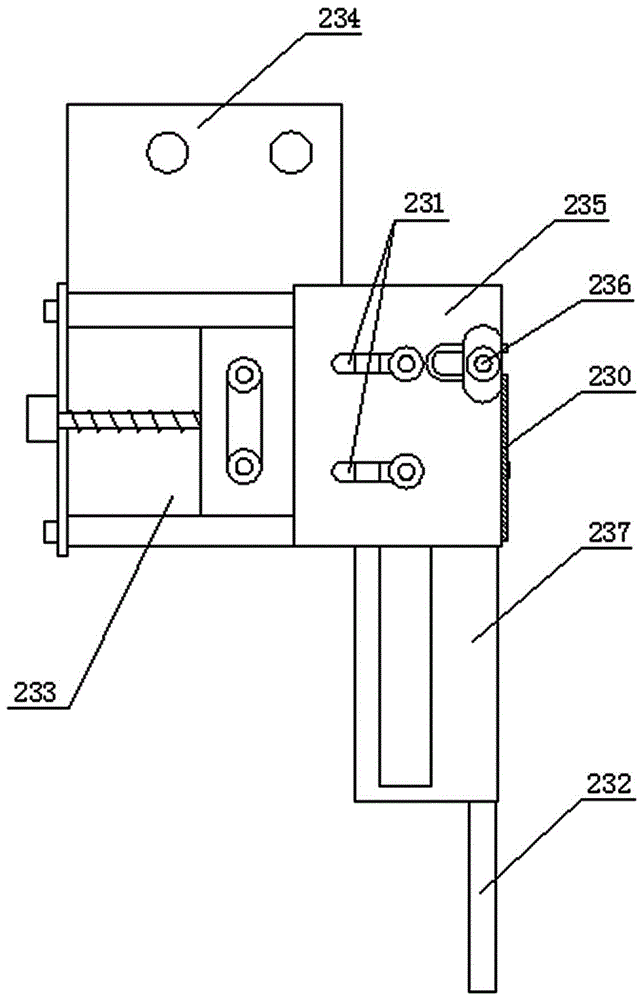

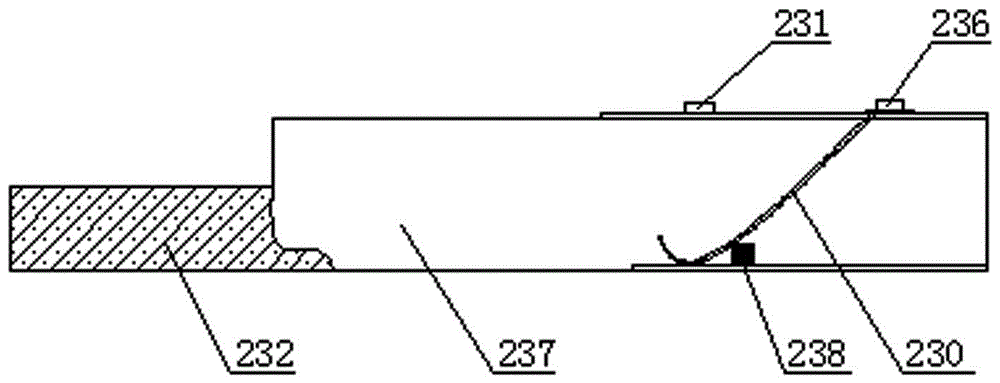

[0022] Such as Figure 1 to Figure 5 Shown, a kind of automatic sawing machine, in order to electric carbon cutting saw, this sawing machine comprises frame 2, two adjacent sides of frame 2 are provided with blanking channel I5 and blanking channel II29 respectively, the blanking channel II29 The top is connected with a guide plate 6, the top of the frame 2 is provided with a rectangular baffle 1, one side of the baffle 1 is provided with an inlet 16, and the frame 2 outside the baffle 1 is also provided with an arched Safety cover 27, be positioned at this baffle plate 1 inner frame 2 and be provided with processing table top 7, be provided with mold clamping mechanism, cutting saw mechanism, positioning mechanism I and positioning mechanism II on processing table top 7; Cutting saw mechanism comprises slide plate 4, Double slide rail 8, air cylinder II26, frequency conversion motor 3 and grinding wheel 21, the two ends of the slide plate 4 cooperate with the double slide rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com