A viscous material injection device

A viscous, material-like technology, applied in the field of injection devices, can solve problems such as troublesome operation, affecting the movement of the piston, and inconvenient holding, and achieve the effects of reducing resource waste, reasonable structural design, and avoiding a large number of residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

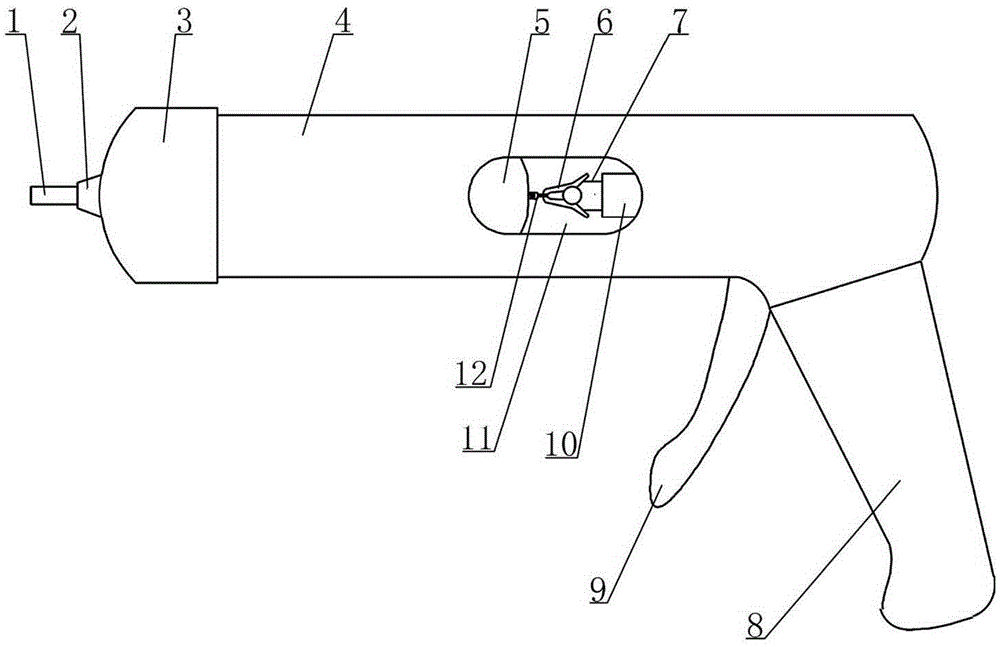

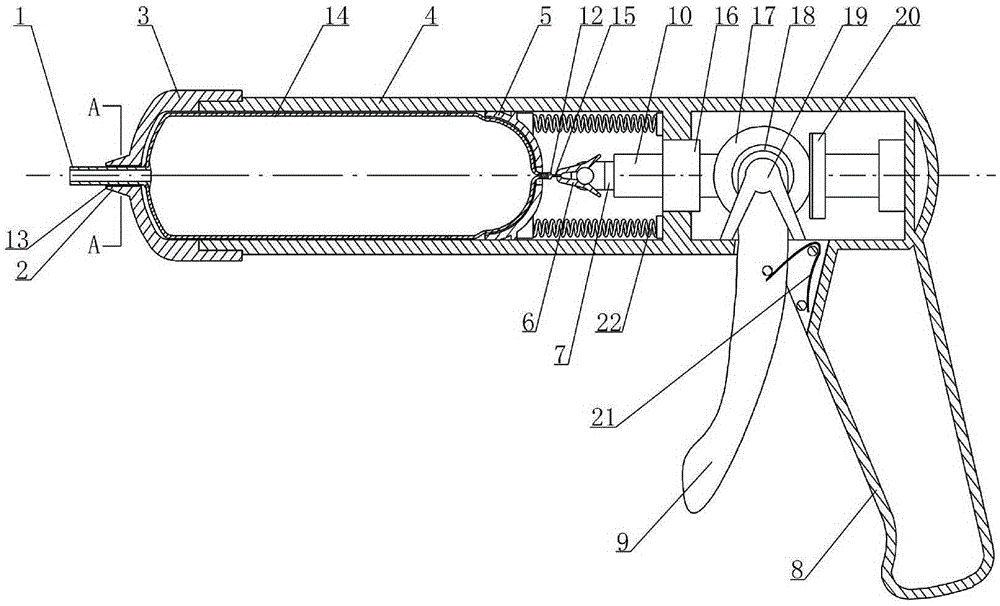

[0035] see figure 1 , 2 As shown, a viscous material injection device disclosed in the present invention is mainly composed of five major parts such as a housing, a material bag 14, a pusher bowl 5, a screw extrusion assembly and a trigger drive assembly.

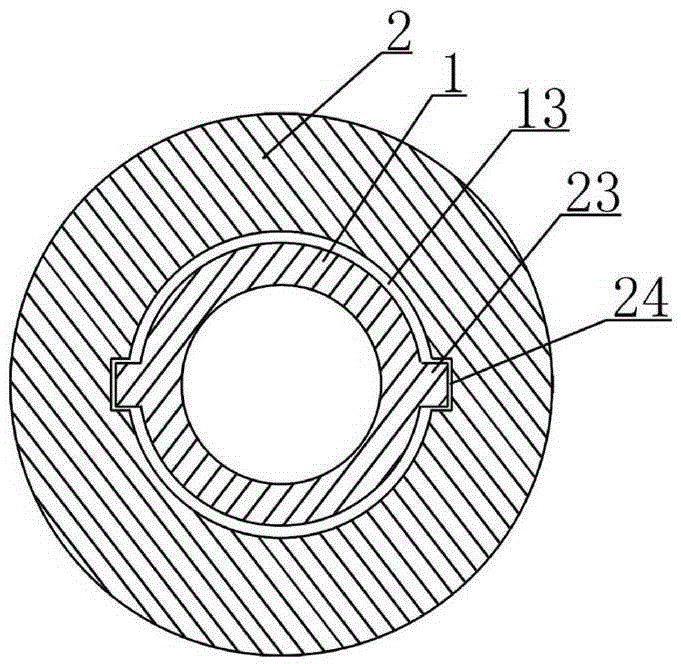

[0036] see figure 1 , 2 , 7, the housing is composed of a cylinder 4, an end cap 3 and a handle 8; wherein the end cap 3 is located at the front end of the cylinder 4, and the two can be freely disassembled through threaded cooperation, and other Connection methods for easy disassembly, such as swivel, buckle, etc., a conical seat 2 is provided on the front side of the end cap 3, and a through hole 13 is provided in the conical seat 2. The cylinder body 4, the end cap 3, and the conical seat 2 and the through hole 13 are coaxial; the handle 8 extends downward from the rear end of the cylinder 4, and the two form a gun shape for easy handling.

[0037] see figure 2 , 6 , 7, the material bag 14 is in the shape of a tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com