Method for preparing hollow tubular activated carbon electrode material for supercapacitor

A technology for supercapacitors and electrode materials, which is applied in the field of preparation of supercapacitor electrode materials, can solve the problems of no mesoporous activated carbon materials for supercapacitors, and achieve the effects of increasing additional economic value, reducing mining, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

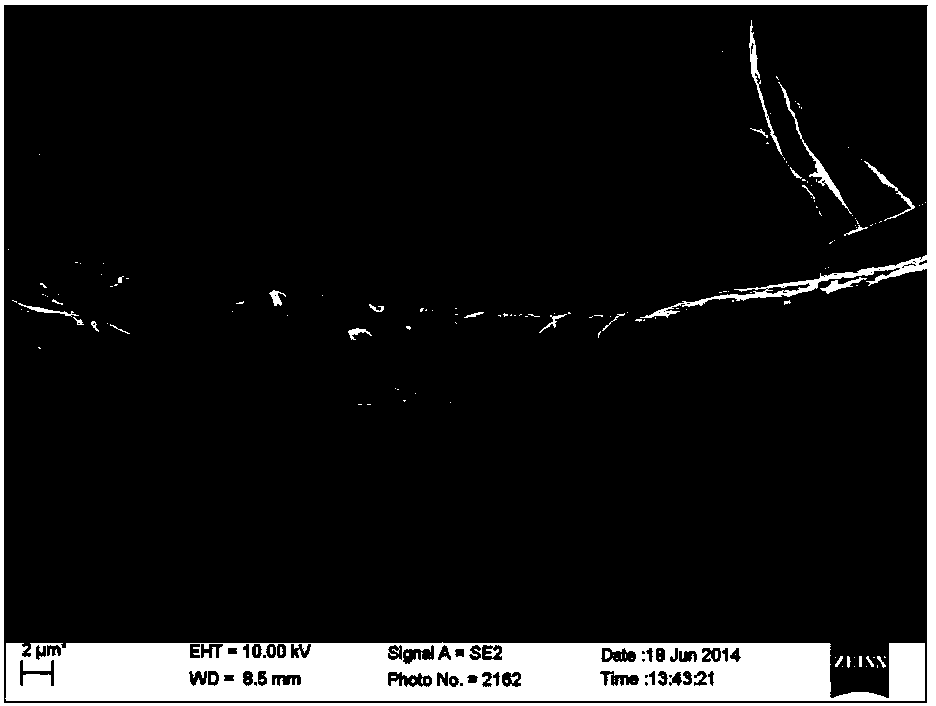

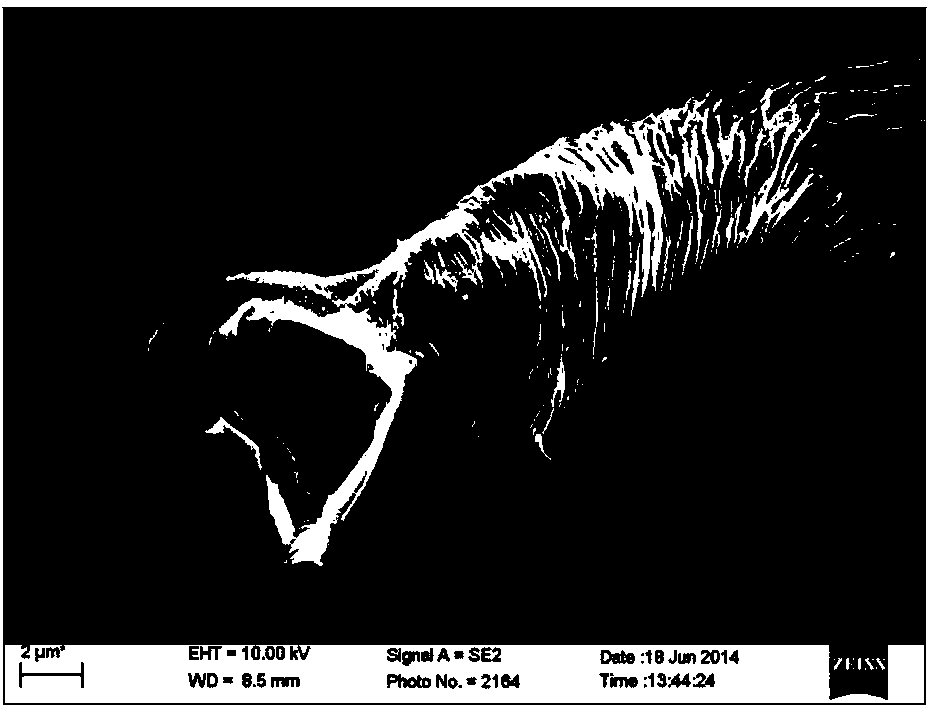

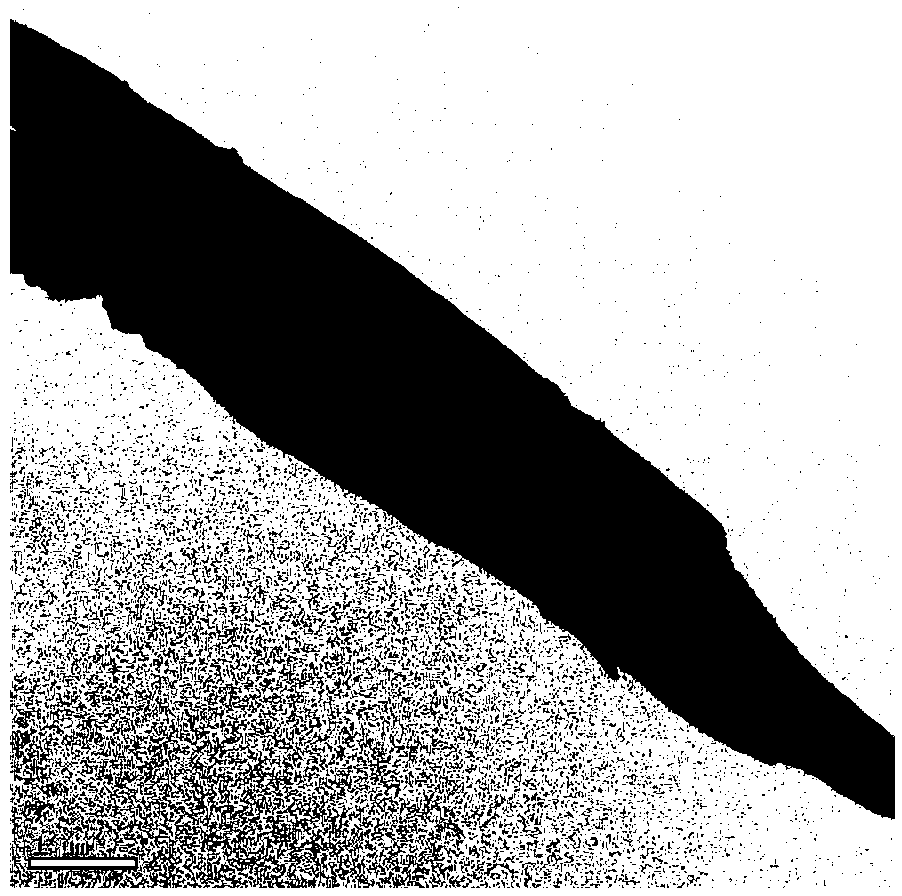

Image

Examples

Embodiment 1

[0035] Step 1: Wash the cotton, remove the sundries and grease, and get clean, silky cotton;

[0036] Step 2: Vacuum dry the clean cotton at 80°C;

[0037] Step 3: Place the dried cotton in a crucible, under nitrogen, at 2°C min -1 The heating rate is increased to 300°C, and the carbonization is carried out at a constant temperature for 30 minutes;

[0038] Step 4: Mix the carbonized cotton obtained in Step 3 with the alkaline activator at a mass ratio of 2:1, and heat the mixture at a temperature of 2°C min -1 The heating rate is increased to 700°C, and nitrogen protection gas is used throughout the process;

[0039] Step 5: The activated carbon material obtained in step 4 is cooled to room temperature with the furnace, washed to neutrality, and then dried at a temperature of 100°C to obtain a hollow activated carbon electrode material for a supercapacitor.

Embodiment 2

[0041] Step 1: Same as Step 1 of Example 1

[0042] Step 2: Same as Step 2 of Example 1

[0043] Step 3: Place the dried cotton in a crucible, under nitrogen, at 5°C min -1 The heating rate is raised to 400 ° C, and the carbonization is carried out at a constant temperature for 30 minutes;

[0044] Step 4: Mix the carbonized cotton obtained in Step 3 with the alkaline activator at a mass ratio of 3:1, and heat the mixture at a temperature of 3°C min -1 The heating rate is increased to 800°C, and nitrogen protection gas is used throughout the process;

[0045]Step 5: The activated carbon material obtained in step 4 is cooled to room temperature with the furnace, washed to neutrality, and then dried at a temperature of 100°C to obtain a hollow activated carbon electrode material for a supercapacitor.

Embodiment 3

[0047] Step 1: Same as Step 1 of Example 1

[0048] Step 2: Same as Step 2 of Example 1

[0049] Step 3: Put the dried cotton in a crucible, under nitrogen condition, at 10°C min -1 The heating rate is increased to 500°C, and the carbonization is carried out at a constant temperature for 60 minutes;

[0050] Step 4: Mix the carbonized cotton obtained in Step 3 with the alkaline activator at a mass ratio of 4:1, and heat the mixture at a temperature of 5°C min -1 The heating rate is increased to 900°C, and nitrogen protection gas is used throughout the process;

[0051] Step 5: The activated carbon material obtained in step 4 is cooled to room temperature with the furnace, washed to neutrality, and then dried at a temperature of 100°C to obtain a hollow activated carbon electrode material for a supercapacitor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com