Urea hydrolyzing ammonia production system and process applied to denitration in thermal power plant

A technology of urea hydrolysis and thermal power plants, which is applied in the field of urea hydrolysis ammonia production system, which can solve problems such as unfavorable adaptation to rapid peak regulation of units, high cost of urea hydrolysis reactor, and hidden safety hazards in operation, so as to reduce corrosion risk and ensure use Life expectancy and the effect of reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

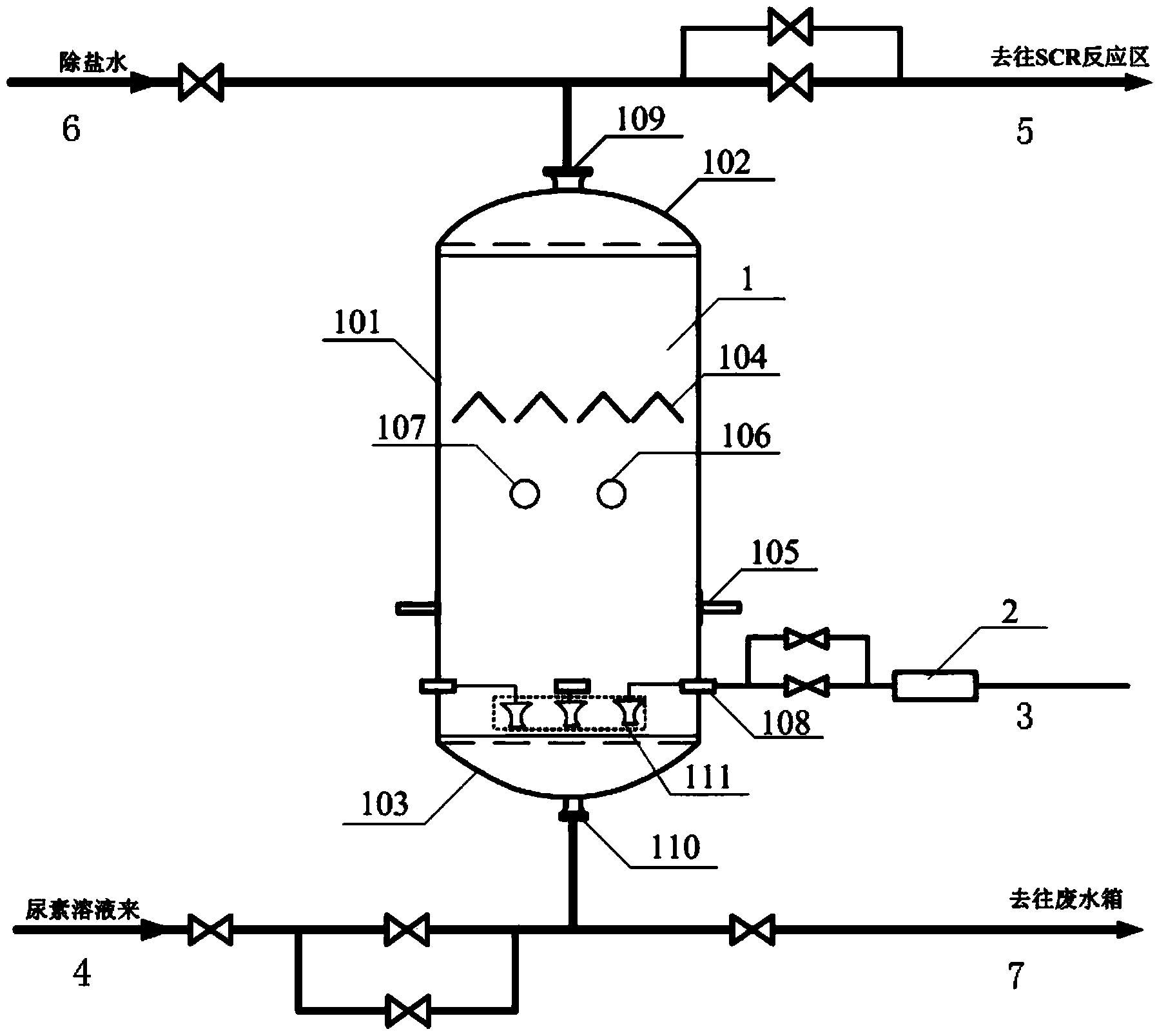

[0031] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

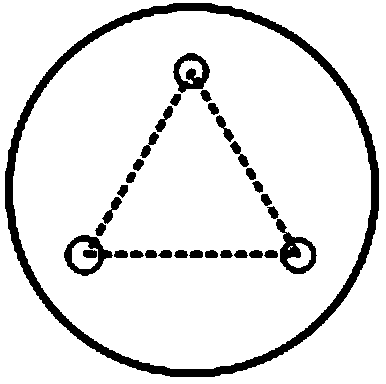

[0032] refer to figure 1As shown, a urea hydrolysis ammonia production system applied to thermal power plant denitrification provided by the present invention includes a vertical hydrolysis reactor 1, a steam pipeline 3, a urea solution injection pipeline 4 and a product gas discharge pipeline 5, This vertical hydrolysis reactor 1 comprises reactor barrel 101, reactor upper head 102, reactor lower head 103, and reactor barrel 101 is provided with fixture 105, is used for fixing vertical hydrolysis reactor 1, reaction A pressure gauge interface 106 and a liquid level gauge interface 107 are provided in the middle of the device barrel 101, and the pressure gauge interface 106 and the liquid level gauge interface 107 are respectively equipped with a pressure gauge and a liquid level gauge. The reactor upper head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com