High-durability waterproof anti-cracking mortar

A technology of waterproof mortar and anti-crack mortar, which is applied in the field of building energy-saving materials, can solve the problems that the bond strength and waterproofness cannot be maintained for a long time, and the durability is not good, and achieve high bond strength and freeze-thaw durability , The effect of prolonging the life of the insulation system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

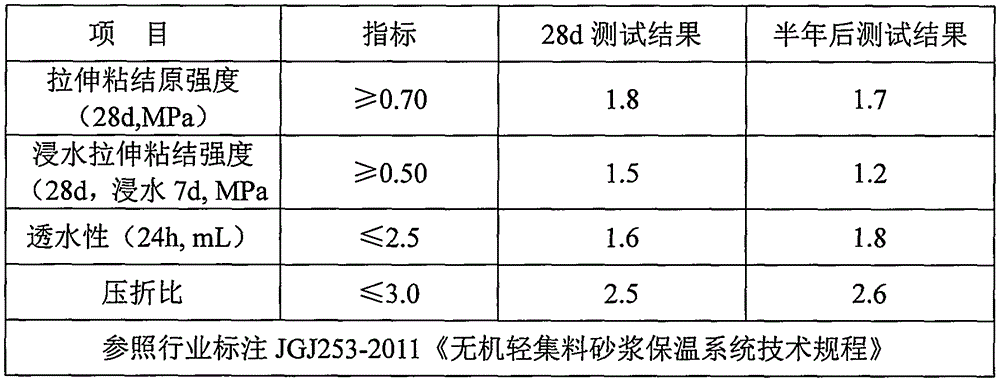

[0025] A waterproof and anti-cracking mortar with good durability, its components and proportions (percentage by weight) are: 35% cement, 57% sand, 5% fly ash, 1% polymer latex powder, 0.3% waterproofing agent, modified Sexual fiber 0.4%, auxiliary admixture 1.3%. According to the water-cement ratio of 0.22:1, the fresh mortar was prepared by on-site mixing, and two batches were formed. One batch was cured for 28 days to perform various performance tests, and the other batch continued to be cured for half a year before various performance tests were performed. The results are shown in Table 1. Show:

[0026]

Embodiment 2

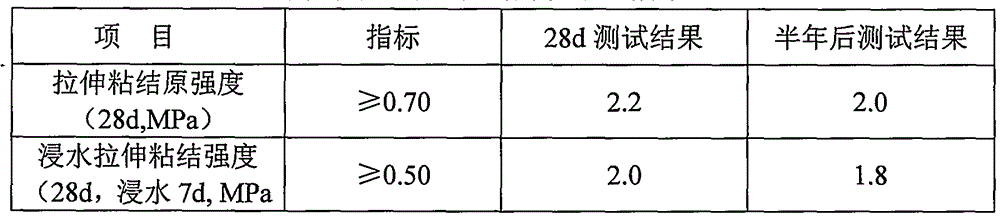

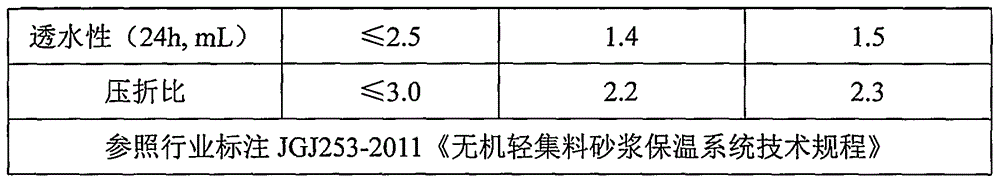

[0028] A waterproof and anti-cracking mortar with good durability, its components and proportions (percentage by weight) are: 40% of cement, 48% of sand, 8% of fly ash, 1.7% of polymer latex powder, 0.6% of waterproofing agent, modified Sexual fiber 0.6%, auxiliary admixture 1.1%. According to the water-cement ratio of 0.22:1, freshly mixed mortar was prepared by on-site mixing, and two batches were formed. One batch was cured for 28 days to perform various performance tests, and the other batch continued to be cured for half a year before various performance tests were performed. The results are shown in Table 2. Show:

[0029]

[0030]

Embodiment 3

[0032] A waterproof and anti-cracking mortar with good durability, its components and proportions (percentage by weight) are: 50% of cement, 37% of sand, 9% of fly ash, 2.1% of polymer latex powder, 0.8% of waterproofing agent, modified Sexual fiber 0.8%, auxiliary admixture 0.3%. According to the water-cement ratio of 0.22:1, freshly mixed mortar was prepared by on-site mixing, and two batches were formed. One batch was cured for 28 days to perform various performance tests, and the other batch continued to be cured for half a year before various performance tests were performed. The results are shown in Table 3. Show:

[0033]

[0034] It can be seen from the above examples that the performance indicators of the mortar prepared by the present invention exceed the requirements of relevant standards after 28 days of curing and after half a year of curing, and the mortar has excellent water resistance, durability and flexible gradient. Moreover, the production and construct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com