Biological hydrogen production device

A technology of biological hydrogen production and pulverization equipment, which is applied in the direction of biochemical cleaning equipment, enzymology/microbiology equipment, biomass post-treatment, etc., and can solve the problem of poor mixing effect of blending and pulverizing substrates, and the stirring device does not stir , long hydrogen production time and other problems, to achieve better fermentation effect, sufficient mixing, and shorten the hydrogen production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

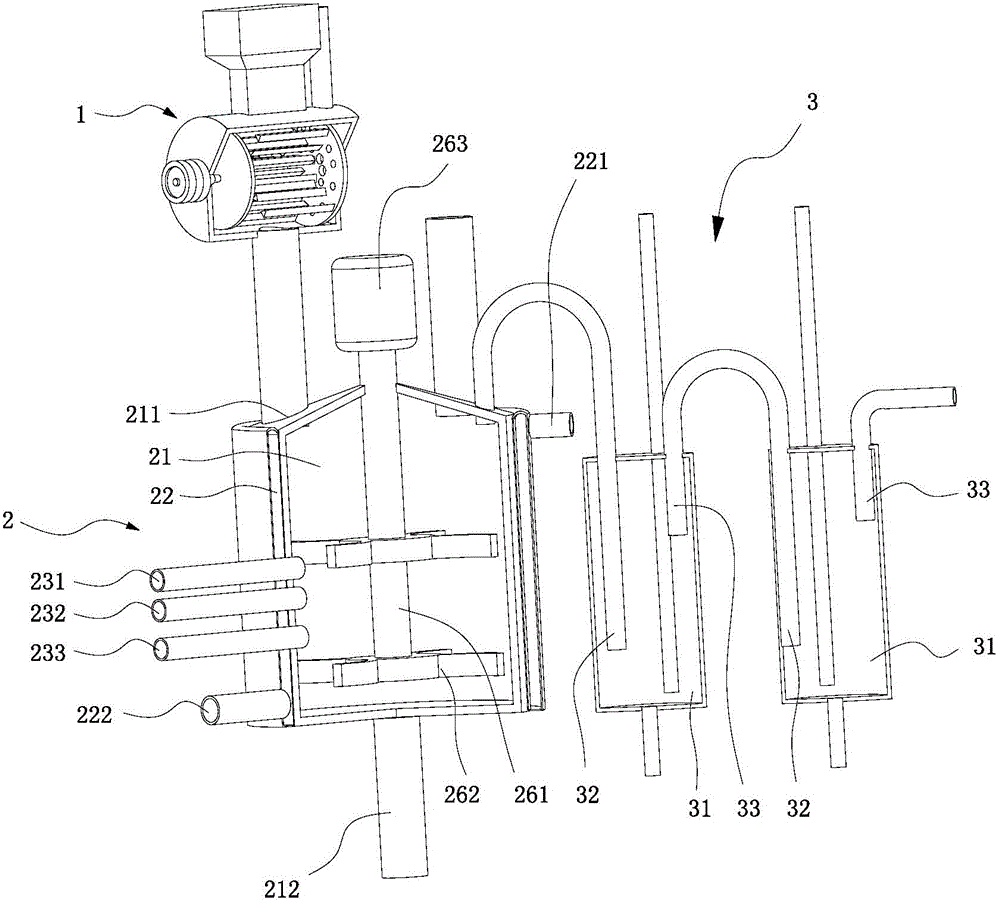

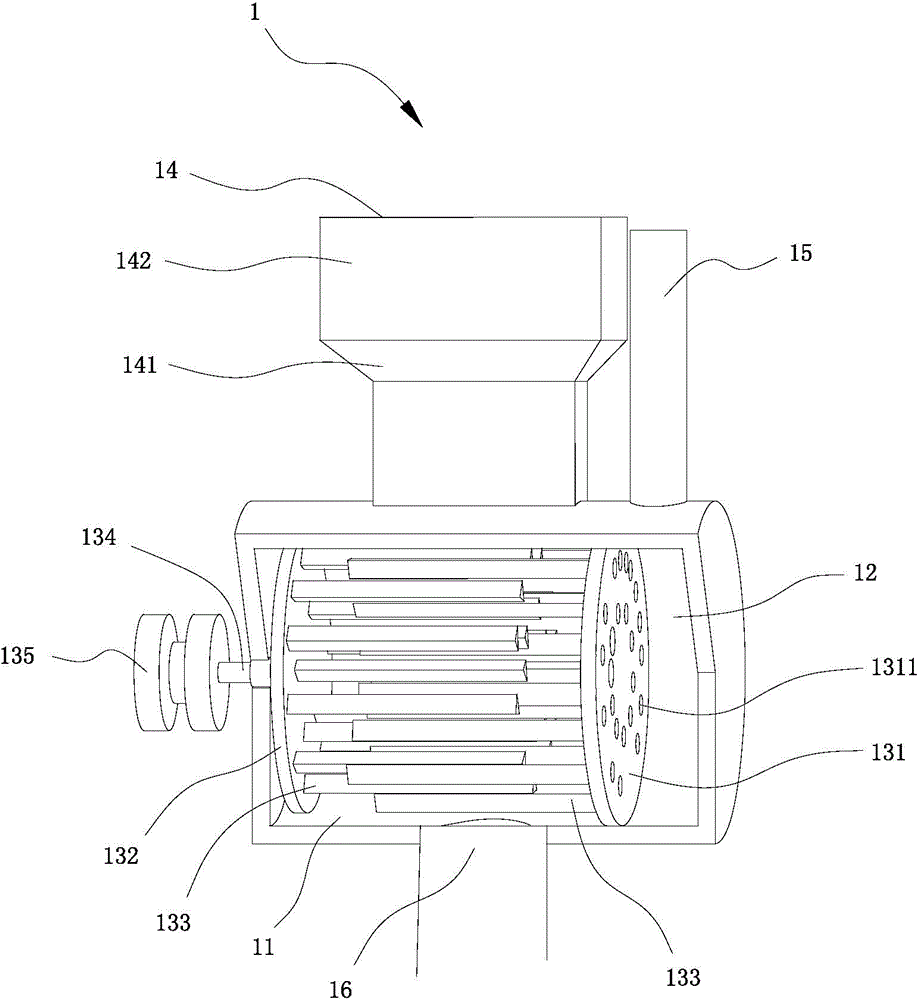

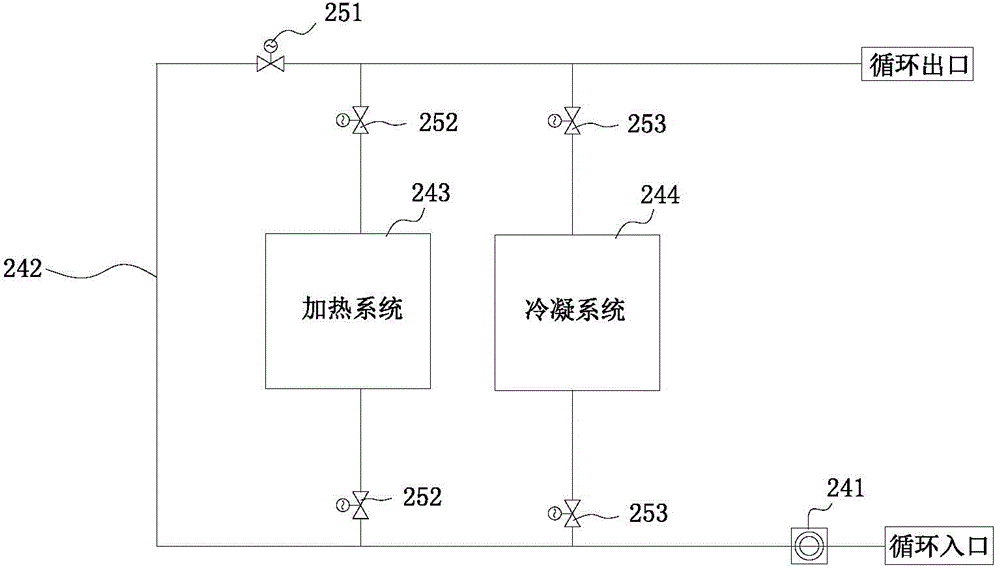

[0026] refer to Figure 1 to Figure 4 , a biological hydrogen production device of the present invention, comprising a pulverizer 1, a fermenter 2 and a gas scrubber 3, the pulverizer 1 includes a casing with an inner cavity, and a pulverizing device is arranged in the inner cavity, and the inner cavity The partition 131 is divided into a crushing chamber 11 and a blending chamber 12. The partition 131 is provided with a plurality of communicating holes 1311 connecting the crushing chamber 11 and the blending chamber 12. The crushing device is located in the crushing chamber 11, and the crushing chamber 11 and The upper end of the mixing chamber 12 is respectively provided with a pulverized substrate inlet 14 and a blended substrate inlet 15, and the lower end of the pulverized chamber 11 is provided with a mixed substrate outlet 16 with a valve. The fermenter 2 is connected with the pulverizer 1, and the gas scrubber 3 is connected with the fermenter 2. The gas scrubber 3 inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com