Partial heat recovery control method and system

A heat recovery and water pump technology, which is applied in the field of some heat recovery control methods and systems, can solve the problems of liquid accumulation in the shell and tube of the heat recovery device, affecting the comfort of the unit, and being unfavorable for large-scale promotion and sales.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

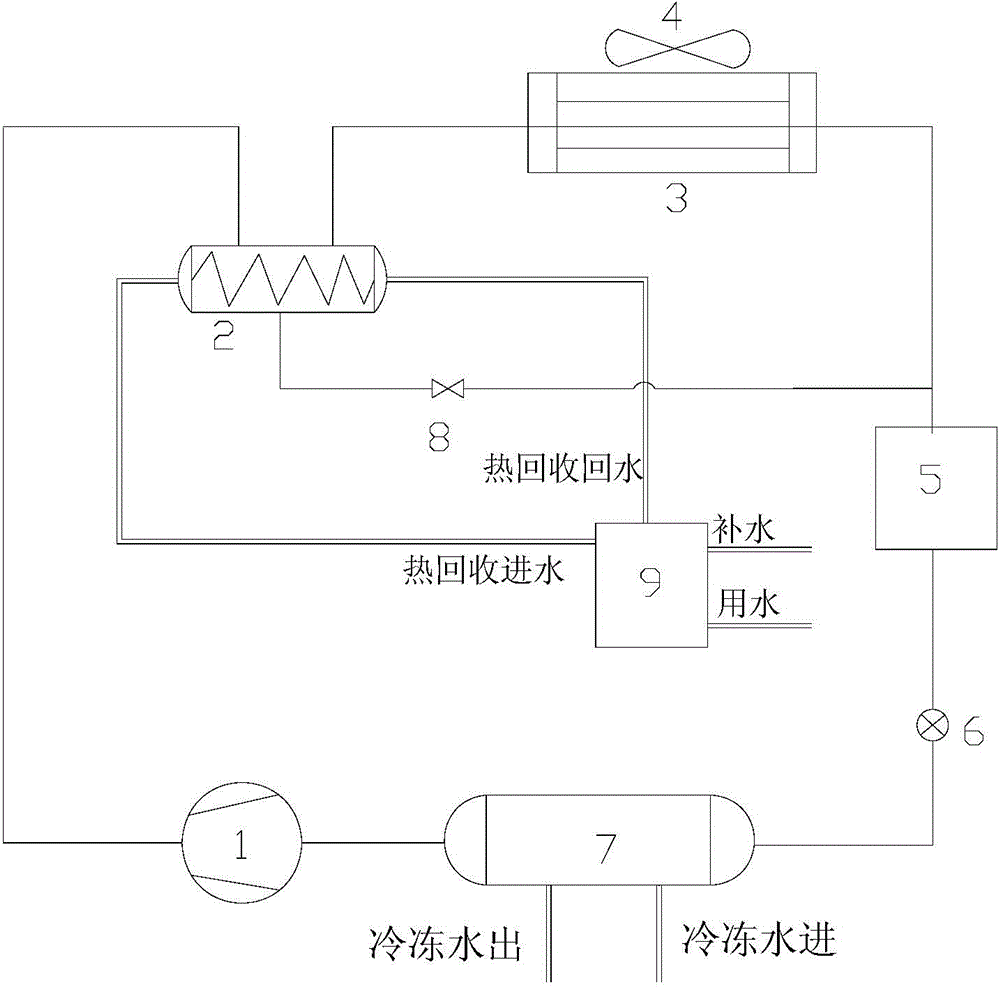

Image

Examples

Embodiment 1

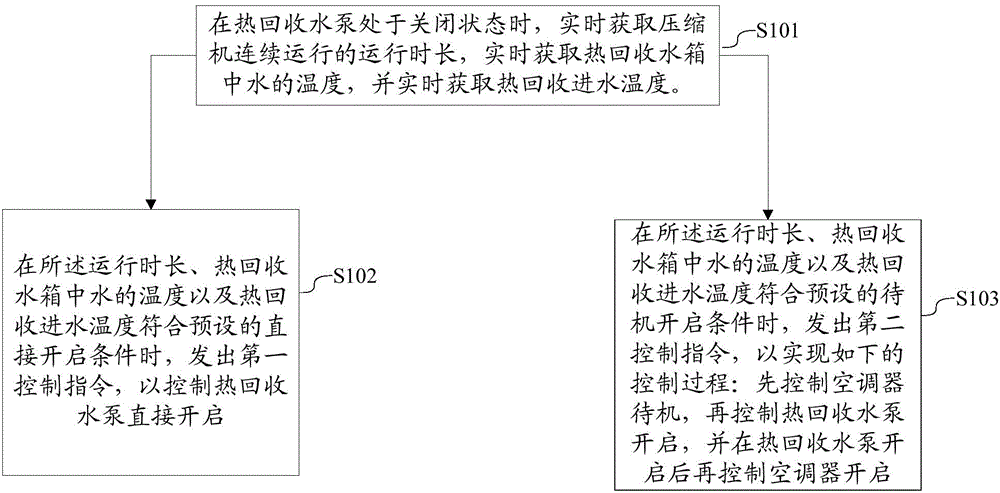

[0060] This embodiment 1 discloses a partial heat recovery control method, refer to figure 2 , the method may include the following steps:

[0061] S101: When the heat recovery water pump is in the off state, obtain in real time the running time of the continuous operation of the compressor, obtain the temperature of the water in the heat recovery water tank in real time, and obtain the temperature of the heat recovery water inlet in real time.

[0062] Wherein, the heat recovery water pump is installed on the water inlet pipeline between the heat recovery water tank and the heat recovery device.

[0063] S102: When the running time, the temperature of the water in the heat recovery water tank, and the temperature of the heat recovery water inlet meet the preset direct start conditions, issue a first control command to control the heat recovery water pump to be directly turned on.

[0064] S103: When the running time, the temperature of the water in the heat recovery water t...

Embodiment 2

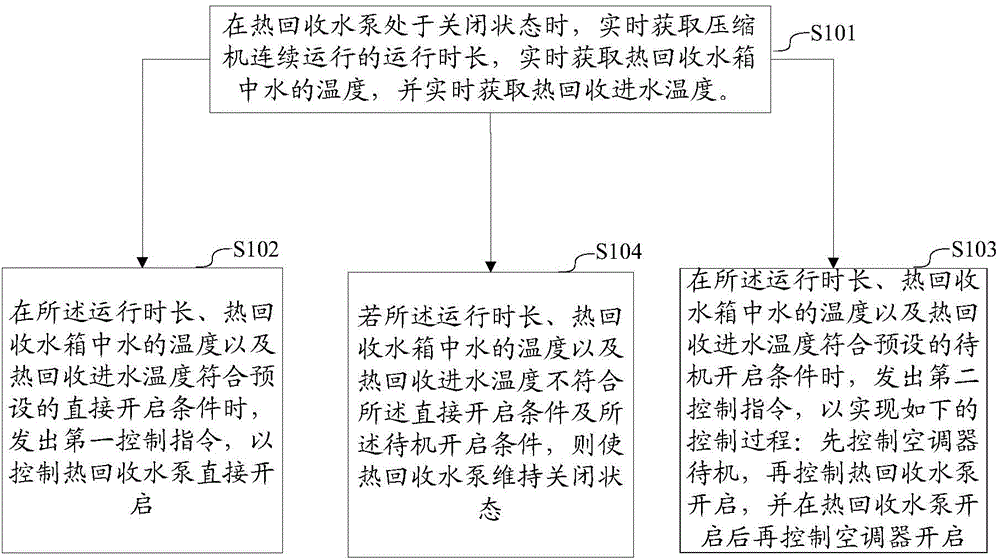

[0074] In the second embodiment, refer to image 3 , the method may also include the following steps:

[0075] S104: When the heat recovery water pump is in the off state, if the running time, the temperature of the water in the heat recovery water tank, and the temperature of the heat recovery water inlet do not meet the direct start condition and the standby start condition, maintain the heat recovery water pump Disabled.

[0076] When t, T 箱 and T 进 If the direct opening condition or standby opening condition is not met, it means that the current unit does not have the sensible heat exchange capacity required for heat recovery, or the current temperature of the water in the water tank is higher than a certain value, and it can be directly used by the user without further processing. heating, so that in this case, it is not necessary to turn on the heat recovery water pump for heat recovery.

Embodiment 3

[0078] In the third embodiment, refer to Figure 4 , the method may also include the following steps:

[0079] S401: When the heat recovery water pump is on, determine whether the unit meets the following conditions: the compressor is off or the T 箱 >T 设 .

[0080] Among them, T 设 is the minimum threshold value of water temperature set.

[0081] S402: If the judgment result is yes, control the heat recovery water pump to turn off;

[0082] S403: If the determination result is negative, keep the heat recovery water pump in an on state.

[0083] When the heat recovery water pump is turned on, if the compressor is turned off, the unit is no longer capable of heat recovery, and the heat recovery water pump needs to be turned off at this time; if T 箱 >T 设 , then the water temperature of the water tank has reached the user's use requirements, and it is not necessary to continue to heat it with heat recovery, so that the heat recovery water pump can be turned off to stop heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com