A transparent heating furnace

A heating furnace and transparent technology, which is applied in the field of heating furnaces, can solve the problems of long distance between the inner tube and the outer tube, increased cost, and it is not conducive to adjusting the angle of the observation window, etc., and achieves the effect of thermal insulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

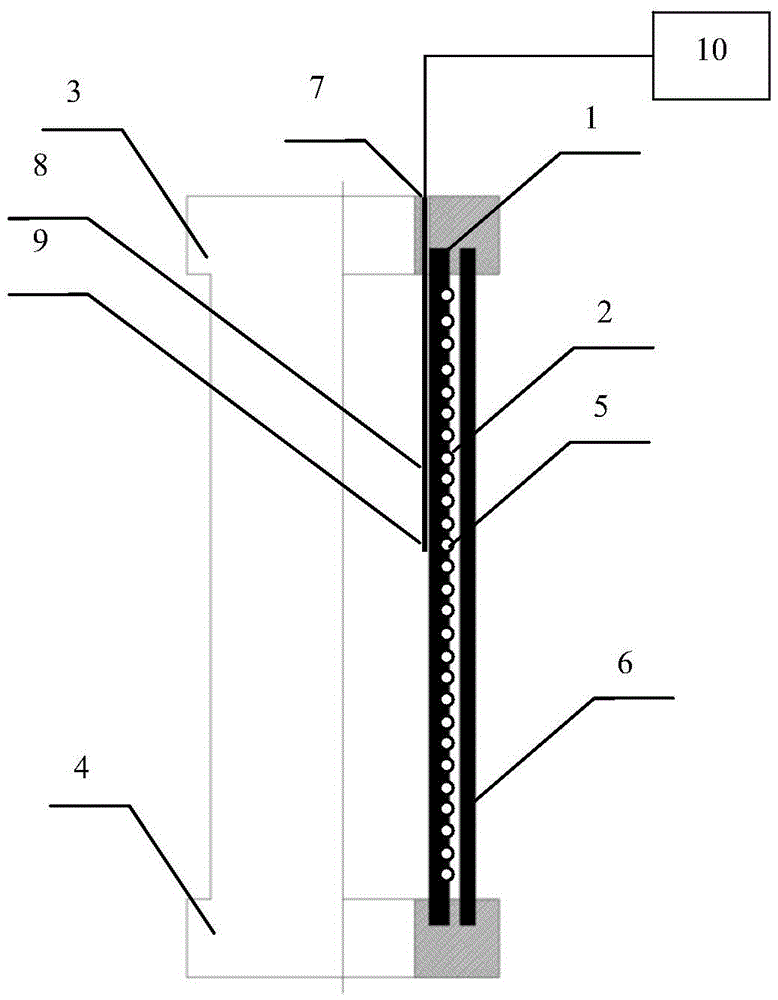

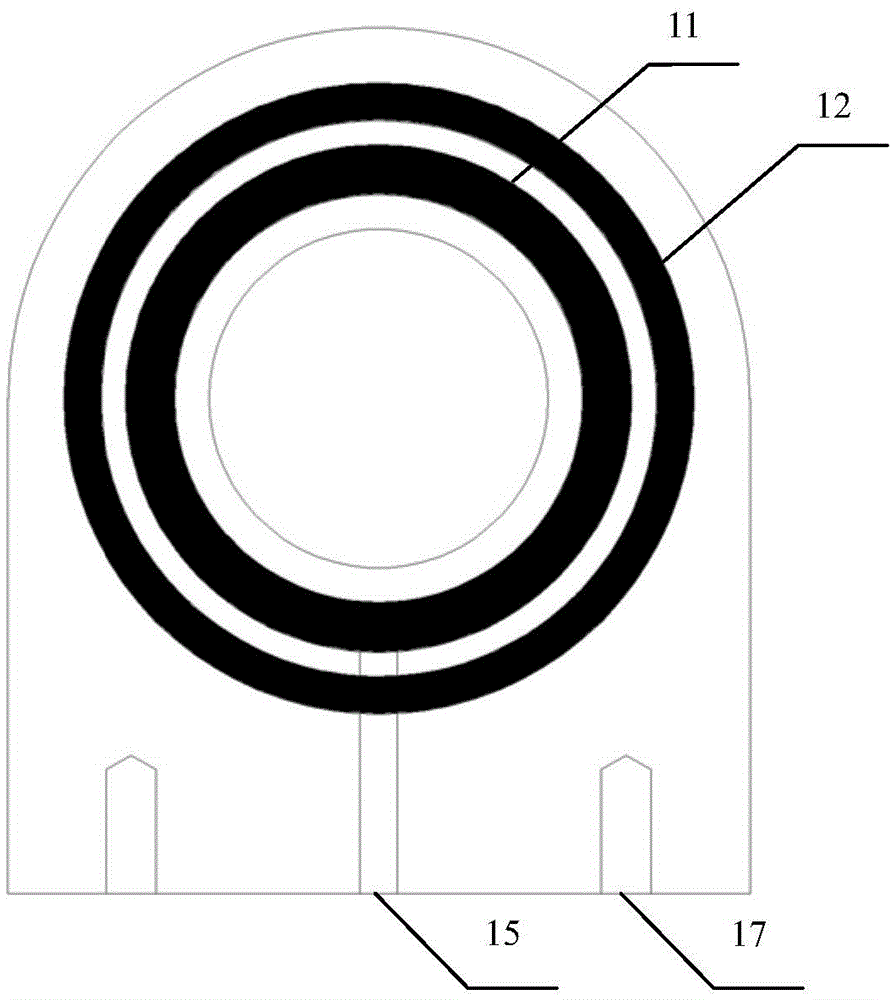

Embodiment 1

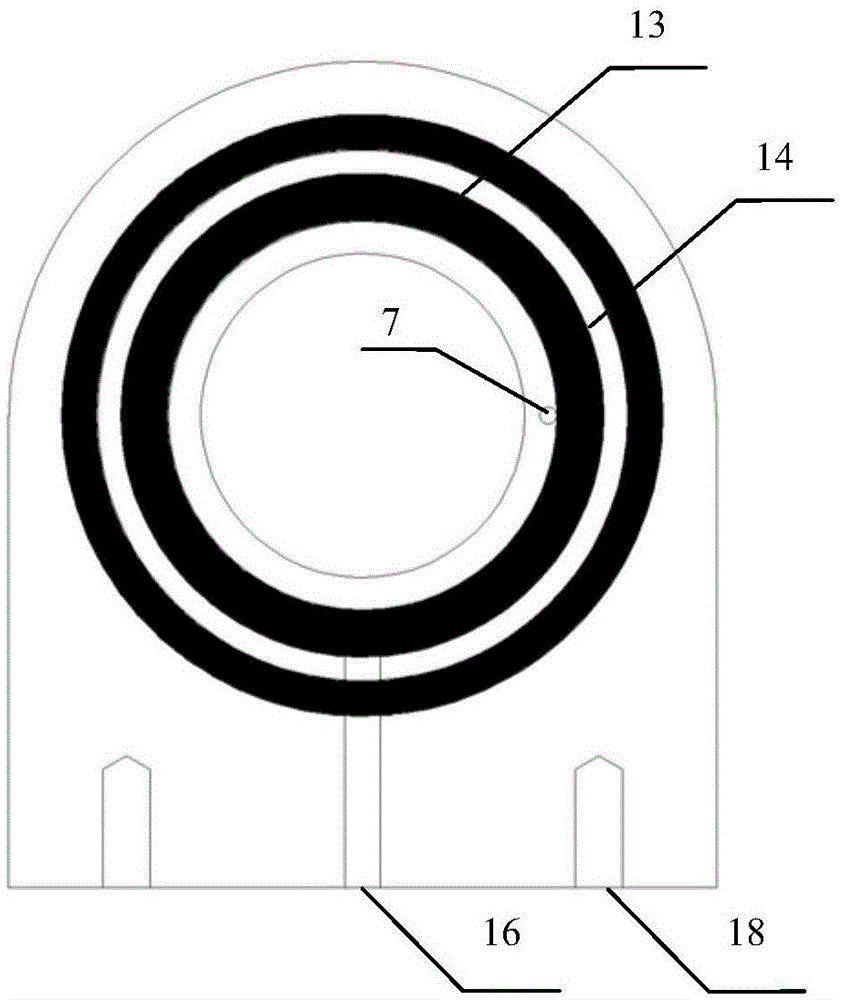

[0063] The diameter of the inner tube is 66mm and the height is 300mm; the diameter of the outer tube is 110mm and the height is 300mm. A support frame is provided on the outer wall of the inner tube, and there is a card slot on the support frame. The heating element is a silicon carbide rod with a diameter of 8mm. The thermal insulation coating on the outer wall of the outer tube is a gold-plated coating with a thickness of 20nm; A metal-free observation window (length 60mm, width 10mm) is provided along the radial direction. The inner tube has a thickness of 8 mm and the outer tube has a thickness of 3 mm. The temperature control meter uses Xiamen Yudian program temperature control device.

[0064] The implementation results are as follows:

[0065] The heating power can reach 2200W, the maximum heating temperature is 1000°C, it takes 40 minutes to program the temperature from room temperature to 1000°C, and the error is less than 1°C; it can run stably for a long time at ...

Embodiment 2

[0067] The diameter of the inner tube is 180mm and the height is 1000mm; the diameter of the outer tube is 200mm and the height is 1000mm. The outer wall of the inner tube is provided with a spiral groove, and the heating element is Cr20Ni80 electric furnace wire with a diameter of 2.0mm. The thermal insulation coating on the outer wall of the outer tube is a nickel-tungsten alloy coating with a thickness of 50nm; There is a metal-free observation window (length 500mm, width 30mm). The inner tube has a thickness of 20 mm and the outer tube has a thickness of 10 mm. The temperature control meter uses Xiamen Yudian program temperature control device.

[0068] The implementation results are as follows:

[0069] The heating power can reach 10000W, the maximum heating temperature is 1000°C, it takes 20 minutes to program the temperature from room temperature to 1000°C, and the error is less than 1°C; it can run stably for a long time at 950°C, and the heating current is not highe...

Embodiment 3

[0071] The inner tube diameter is 30mm and the height is 200mm; the outer tube diameter is 50mm and the height is 200mm. The outer wall of the inner tube is provided with a spiral groove, and the heating element is a silicon-molybdenum rod with a diameter of 3mm. The thermal insulation coating on the outer wall of the outer tube is a zirconia coating with a thickness of 10nm; Observation window with or without metal coating (length 30mm, width 10mm). The inner tube has a thickness of 6 mm and the outer tube has a thickness of 3 mm. The temperature control meter uses Xiamen Yudian program temperature control device.

[0072] The implementation results are as follows:

[0073] The heating power can reach 1000W, the maximum heating temperature is 950°C, it takes 45 minutes to program the temperature from room temperature to 900°C, and the error is less than 1°C; it can run stably for a long time at 900°C, and the heating current is not higher than 3A. Under any heating condition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com