Three-dimensional atom probe sample preparation first stage polishing equipment

An atom probe, three-dimensional technology, applied in the field of first-stage polishing equipment for three-dimensional atom probe sample preparation, can solve the problems of long time for sample preparation, complicated equipment operation, expensive equipment, etc., and achieves easy observation and data collection, flexible Strong sex and weight saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

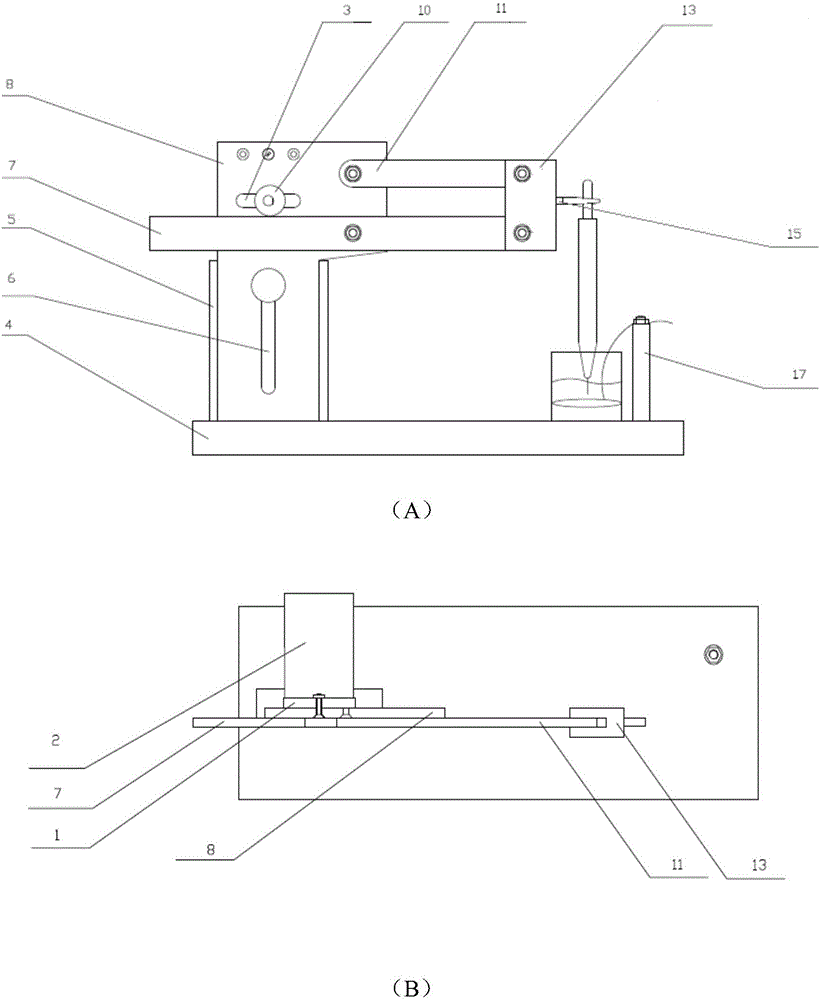

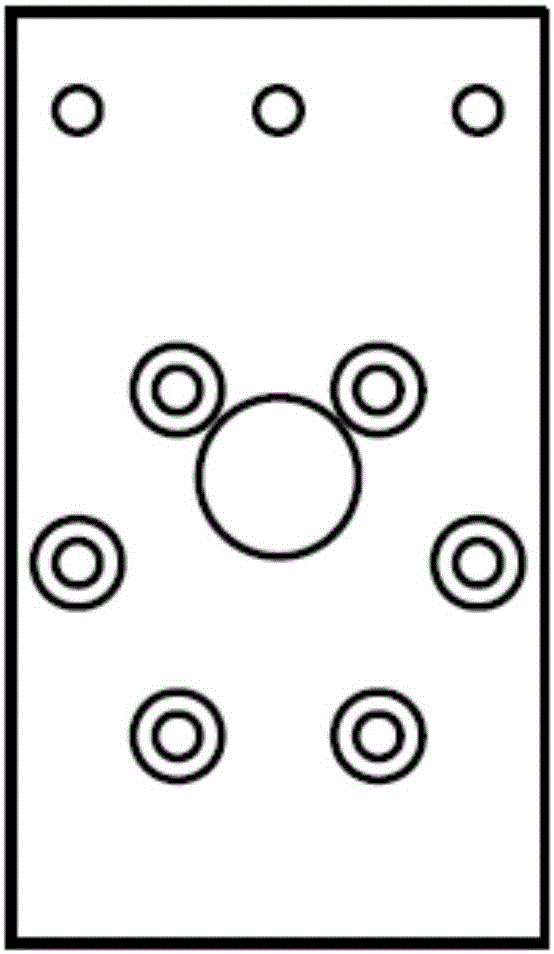

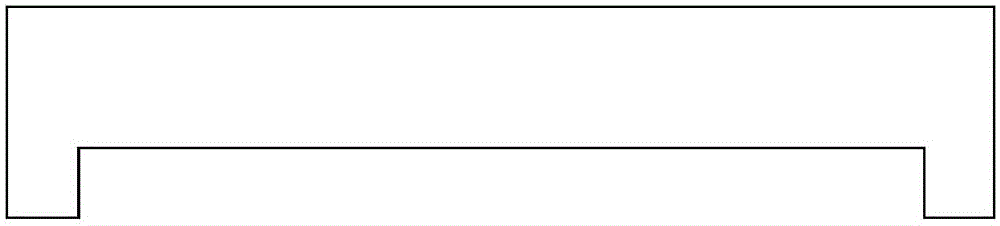

[0029] Insert an alligator clip connected to the anode of the power supply on the pin 15, and clamp the tail of a vertical tweezers. The tip of the tweezers holds the sample to be polished, and the middle of the tweezers is held by a small clip to fix the sample to be polished. Place a beaker filled with polishing liquid under the sample and on the base 4, so that the bottom of the sample can be immersed in the polishing liquid. Wrap one end of the metal wire into a ring and soak it in the polishing solution, and stick it close to the inner wall of the beaker. The middle part is fixed on the top of the column 17 with screws, and the other end is connected to the cathode of the power supply. The lower end of the column 17 is screwed into one end of the base 4 to be fixedly connected. The support plate 5 is a concave plate, the bottom of which is fixed on the end of the base 4 away from the column 17 by three parallel bolts, and the liner 8 is connected and fixed in front of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com