Crystalline silicon solar cell wet chemical treatment method for performing texture surface making and cleaning steps

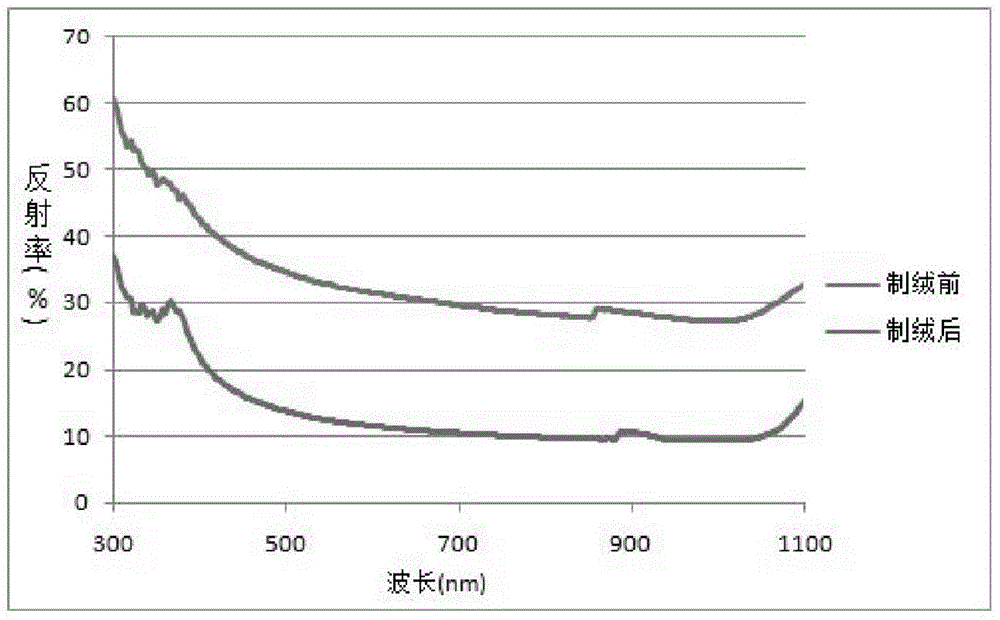

A solar cell and wet chemical treatment technology, which is applied to circuits, photovoltaic power generation, electrical components, etc., can solve problems such as the impact of cleaning effects, general anti-reflection effects, and reduced service life of cleaning liquids, so as to prevent cross-contamination of solutions and avoid unnecessary Uniform etching and improved productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The operation of the velvet section is as follows:

[0041] (1) Provide a pre-treated silicon wafer; the pre-treatment is: put the silicon wafer in the flower basket into pure water to soak and overflow, rinse for 5 minutes, and remove dust, etc. The resistivity of pure water is 10-18MΩ.

[0042] (2) Pre-cleaning the silicon wafer with the first cleaning solution to remove particle impurities and pollution on the surface of the silicon wafer;

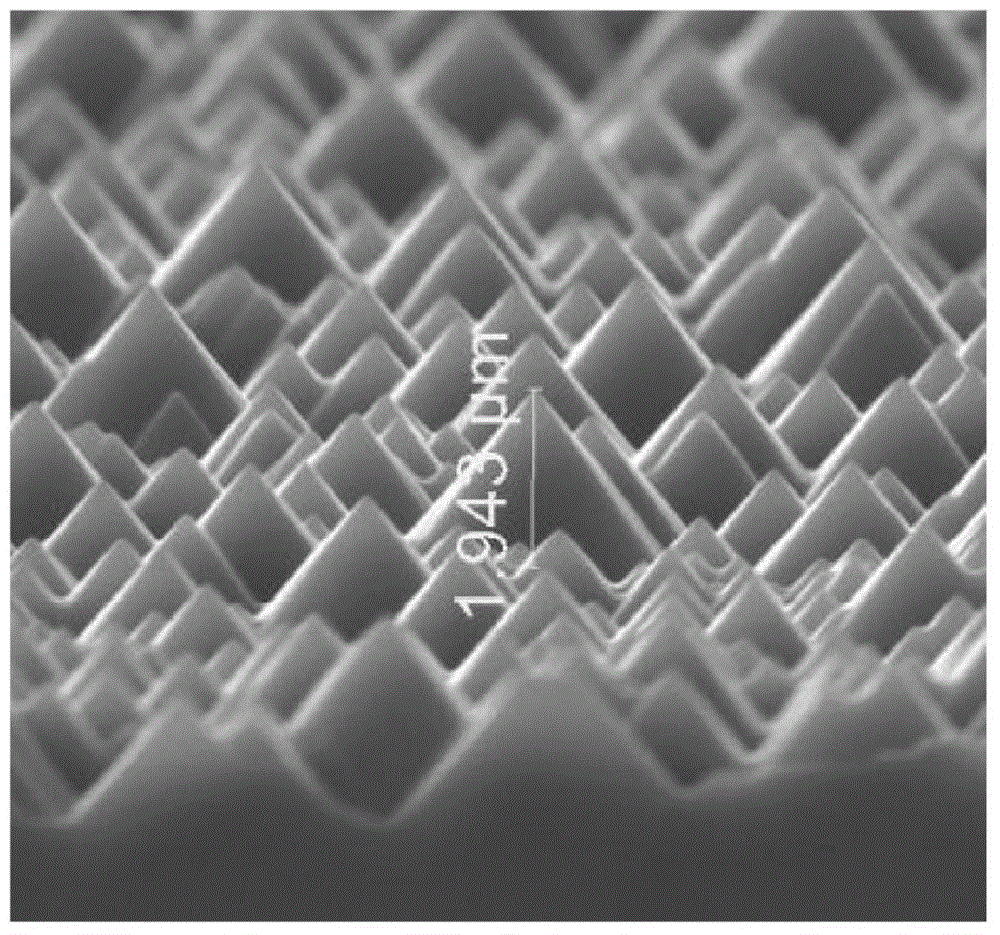

[0043] (3) The silicon wafer is polished with a polishing etchant to corrode the mechanically damaged layer on the surface. The mechanically damaged layer is as follows: image 3 shown;

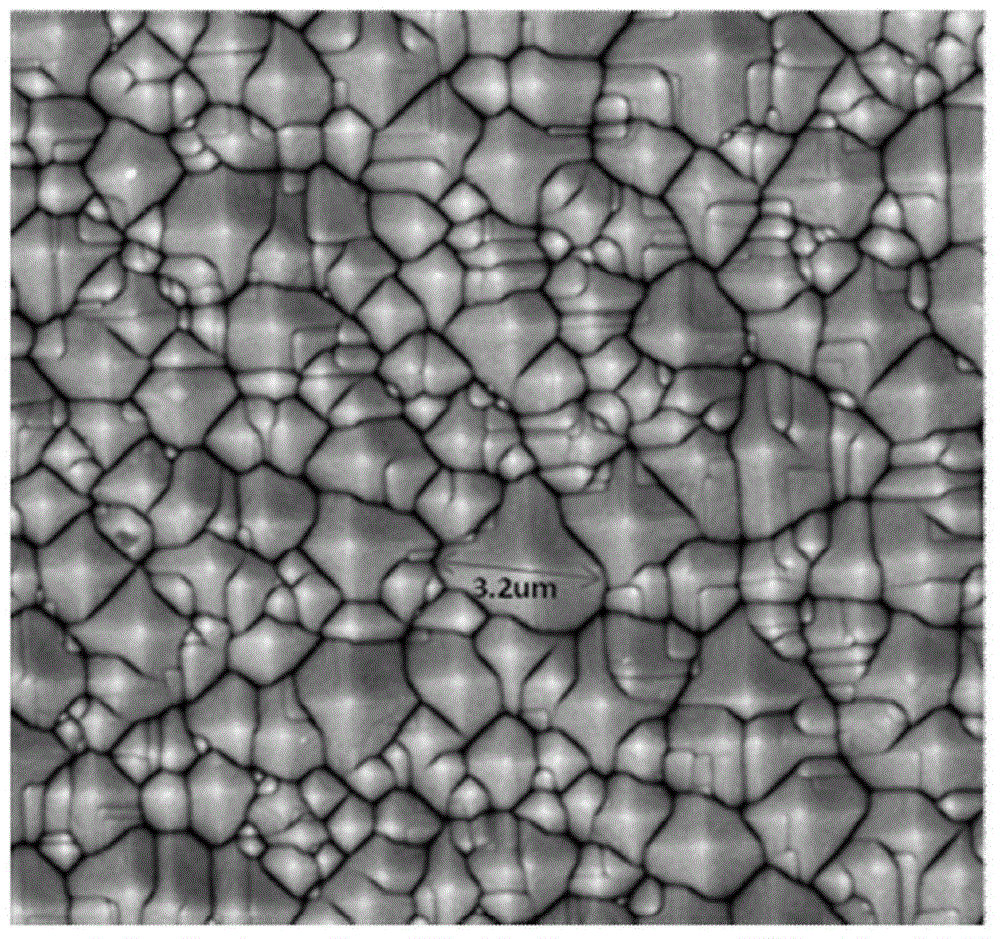

[0044] (4) adopt texturing liquid to carry out texturing process to silicon chip, make its surface form the textured structure;

[0045] (5) Using the second cleaning solution to clean the silicon wafer to remove surface metal ions, neutralize alkaline impurities, and reduce surface chemical residues;

[0046] (6) Treat the silicon wafer wit...

Embodiment 2

[0068] The operation of the velvet section is as follows:

[0069] (1) Provide a pre-treated silicon wafer; the pre-treatment is: put the silicon wafer in the flower basket into pure water to soak and overflow, rinse for 8 minutes, and remove dust, etc. The resistivity of pure water is 10-18MΩ.

[0070] (2) Pre-cleaning the silicon wafer with the first cleaning solution to remove particle impurities and pollution on the surface of the silicon wafer;

[0071] (3) The silicon wafer is polished with a polishing etchant to corrode the mechanically damaged layer on the surface. The mechanically damaged layer is as follows: image 3 shown;

[0072] (4) adopt texturing liquid to carry out texturing process to silicon chip, make its surface form the textured structure;

[0073] (5) Using the second cleaning solution to clean the silicon wafer to remove surface metal ions, neutralize alkaline impurities, and reduce surface chemical residues;

[0074] (6) Treat the silicon wafer wit...

Embodiment 3

[0096] The operation of the velvet section is as follows:

[0097] (1) Provide a pre-treated silicon wafer; the pre-treatment is: put the silicon wafer in the flower basket into pure water to soak and overflow, rinse for 1 min, and remove dust, etc. The resistivity of pure water is 10-18MΩ.

[0098] (2) Pre-cleaning the silicon wafer with the first cleaning solution to remove particle impurities and pollution on the surface of the silicon wafer;

[0099] (3) The silicon wafer is polished with a polishing etchant to corrode the mechanically damaged layer on the surface. The mechanically damaged layer is as follows: image 3 shown;

[0100] (4) adopt texturing liquid to carry out texturing process to silicon chip, make its surface form the textured structure;

[0101] (5) Using the second cleaning solution to clean the silicon wafer to remove surface metal ions, neutralize alkaline impurities, and reduce surface chemical residues;

[0102] (6) Treat the silicon wafer with an o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com