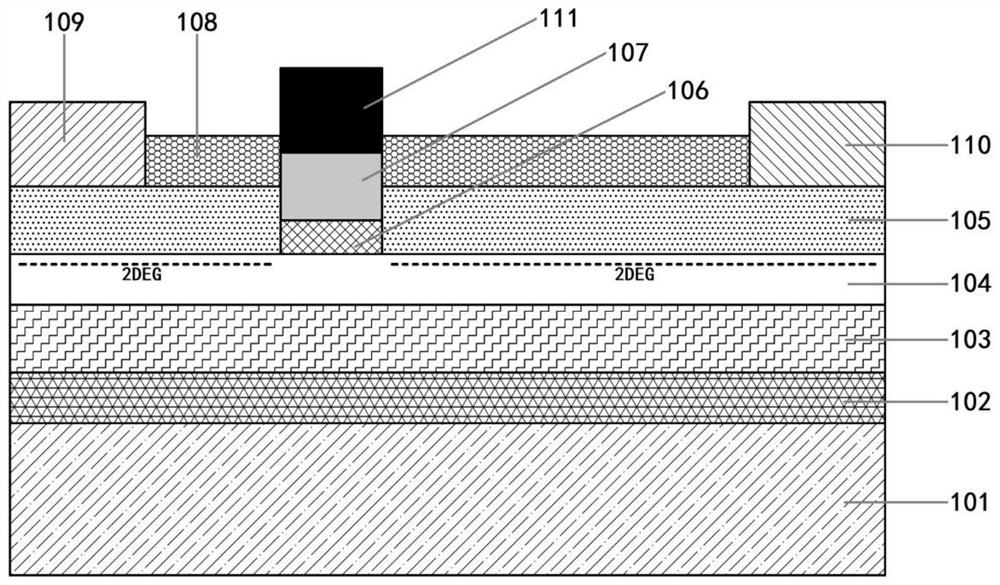

A normally-off high electron mobility transistor and its manufacturing method

A technology with high electron mobility and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve problems such as unfavorable normally closed AlGaN/GaN, low on-resistance, and unresolved P-type layers. Achieve the effect of optimizing the two-dimensional electron gas concentration, avoiding surface damage, and protecting surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A method for manufacturing a normally-off AlGaN / GaN high electron mobility transistor, comprising the following steps:

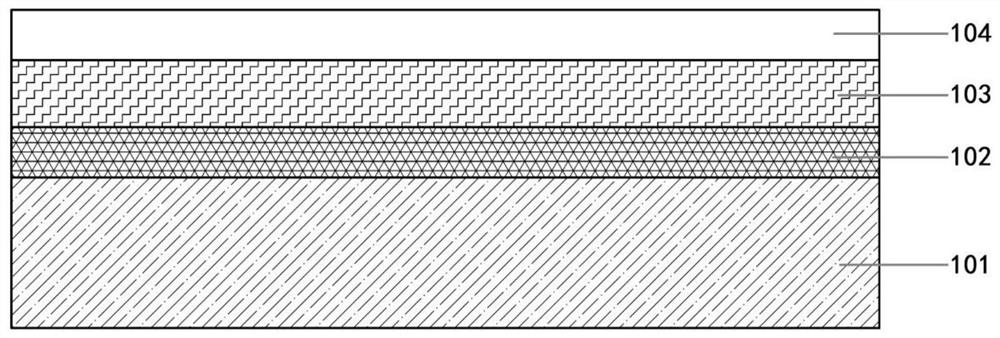

[0049] (1) If figure 2 As shown, a substrate 101 is provided, and a buffer layer 102, a high resistance layer 103 and a GaN channel layer 104 are grown on the substrate 101 in sequence;

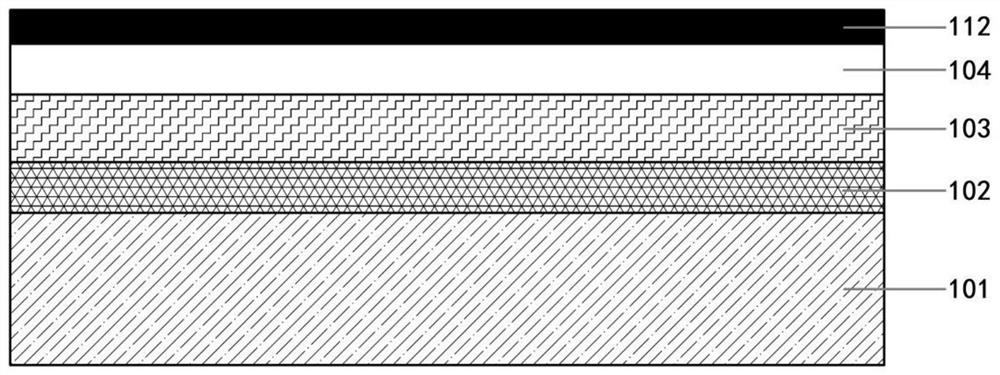

[0050] (2) If image 3 As shown, a first mask layer 112 is deposited on the GaN channel layer 104, and the first mask layer 112 is SiO 2 or SiN;

[0051] (3) If Figure 4 As shown, the first mask layer 112 that needs to grow the region outside the gate AlGaN layer 106 is etched away by using a photolithography etching technique;

[0052] (4) If Figure 5 As shown, the selective epitaxy is performed using the first mask layer 112, the AlGaN barrier layer 105 is grown on the GaN channel layer 104, and the first polycrystalline layer 113 is formed on the first mask layer 112 at the same time;

[0053] (5) If Image 6 As shown, the first polycrystalline layer 113...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com