Rigid-flexible combined circuit board and manufacturing method thereof

A rigid-flexible combination and circuit board technology, which is applied in the manufacture of printed circuits, printed circuits, printed circuit components, etc., can solve the problems of difficulty in opening blind holes, achieve stable dimensions, good surface copper uniformity, and reduce difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

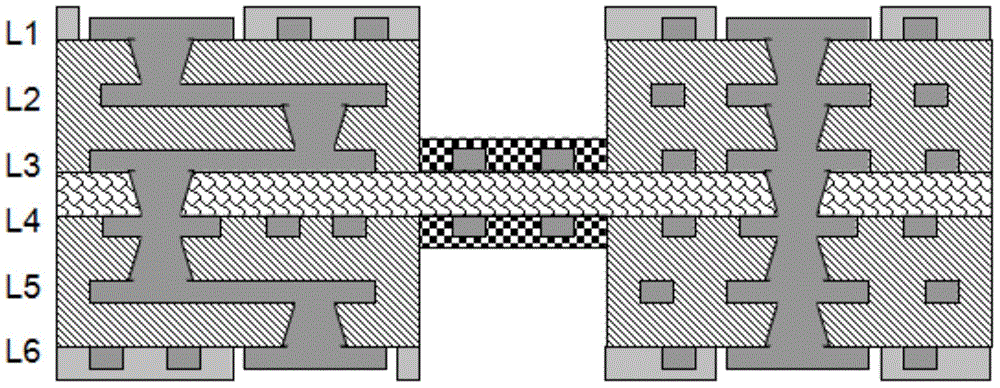

[0044] A rigid-flex circuit board with 6 layers in total, 3 / 4 of which are flexible layers, and the rest are rigid layers. The structure is as figure 1 Shown. The preparation method of the circuit board is as follows:

[0045] 1. Production of flexible core board.

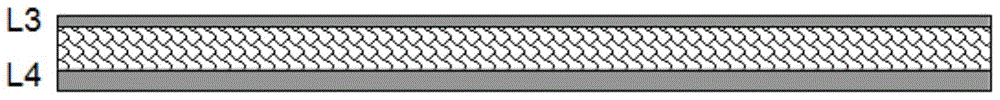

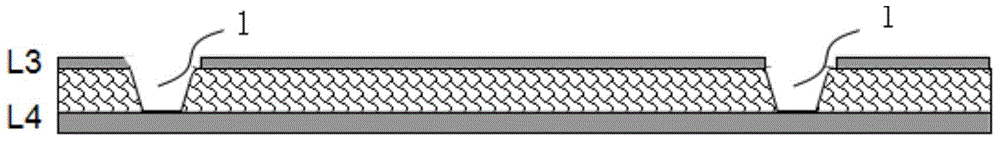

[0046] (1) Drilling: The flexible sheet is made into a copper-yin copper structure with different copper layer thicknesses on both sides in the form of single-sided thinned copper, such as figure 2 Shown, the two sides of the copper layer thickness are H1 and H2 flexible board. Among them, the copper thickness H1 on the L3 surface is 8-10μm, and the copper thickness H2 on the L4 surface is 18-70μm. It is understandable that the thickness of H1 and H2 can be set according to the design requirements, and only H1 is less than H2.

[0047] Before drilling, drill four positioning holes on the four corners of the flexible plate with a drill with a diameter of 3.175mm for the laser drilling machine to locate.

[0048] Use CO af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com