Manufacturing method for colored cotton thermal insulation fabric

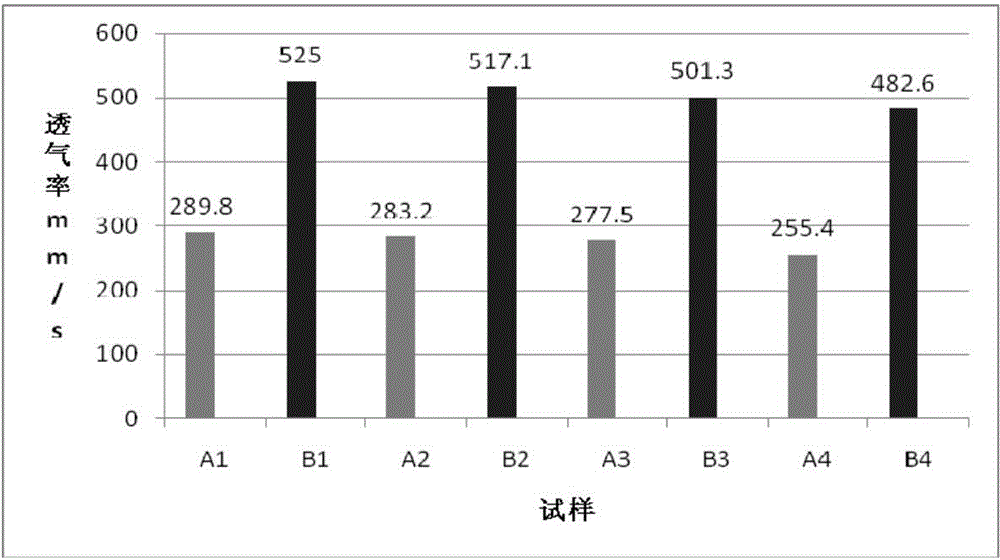

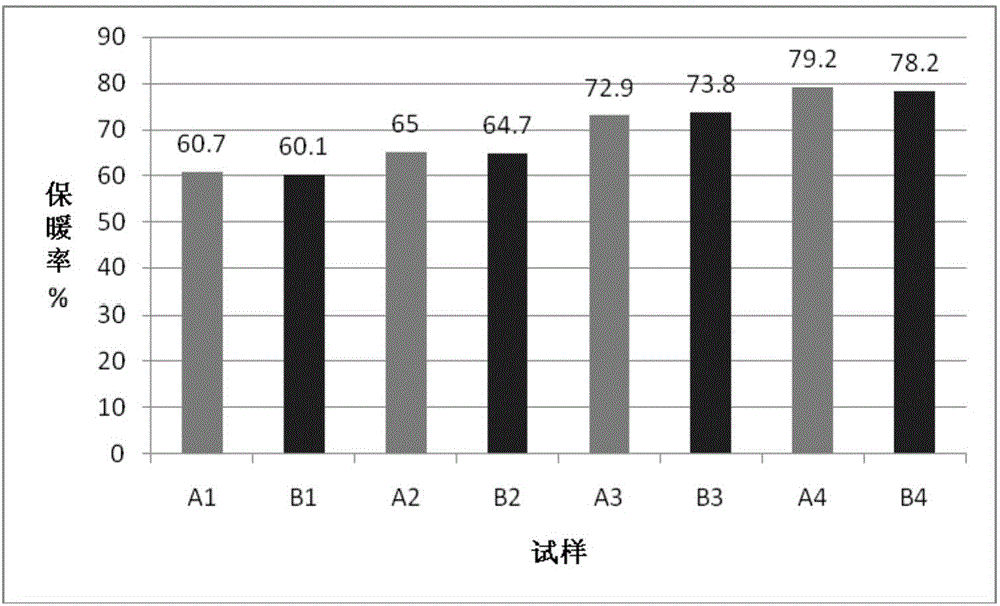

A technology for colored cotton and fabrics, which is applied to the biochemical treatment of enzymes/microbes, biochemical fiber treatment, clothing, etc., which can solve the problems of non-compliance with environmental protection requirements, serious energy consumption, and a large amount of waste liquid, so as to reduce processing procedures and improve production efficiency. Air permeability and energy consumption reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

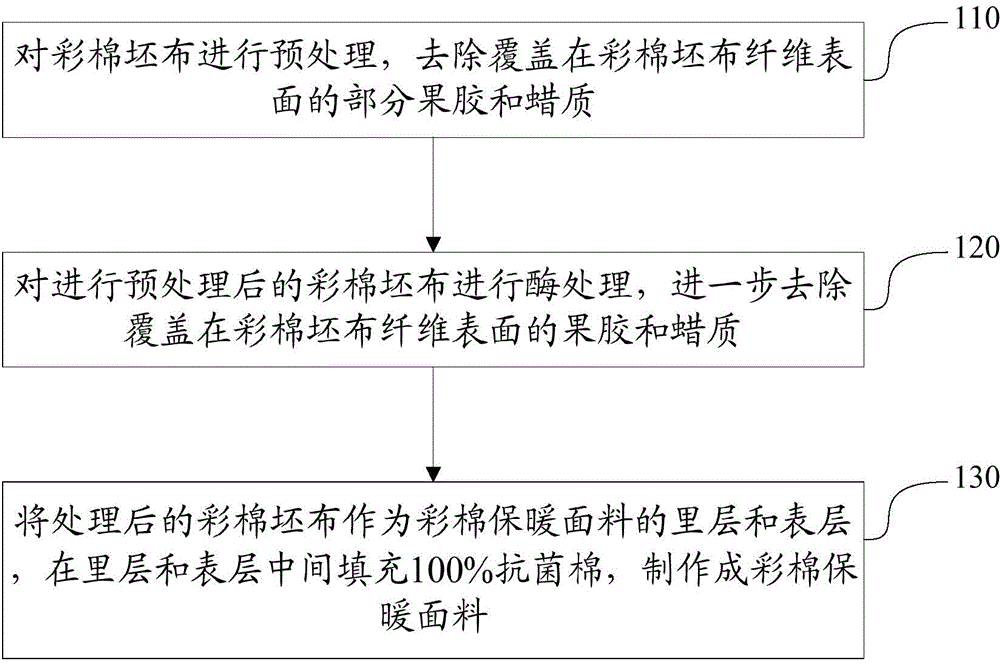

[0022] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0023] Natural colored cotton is a kind of cotton with natural colors. It does not need to be dyed in textile processing, thus reducing the processing steps, correspondingly reducing the discharge of sewage and the treatment of sewage, and avoiding the pollution and pollution of water resources during processing. Prohibition of dyes and toxic auxiliaries on the human body and damage to the environment reduces energy consumption, thereby reducing production costs. In addition, the content of heavy metal elements in colored cotton is all lower than the environmental protection index, and the content of some heavy metals is even lower than that of white cotton, which shows that colored cotton fully meets the environmental protection requirements. Its textiles can be called "the darling of the 21st century" and "the second health...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com