Bilastine orally disintegrating tablet and preparing method thereof

A disintegrating tablet and prescription technology, applied in the field of bilastine orally disintegrating tablets and its preparation, can solve problems such as sensitization and toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

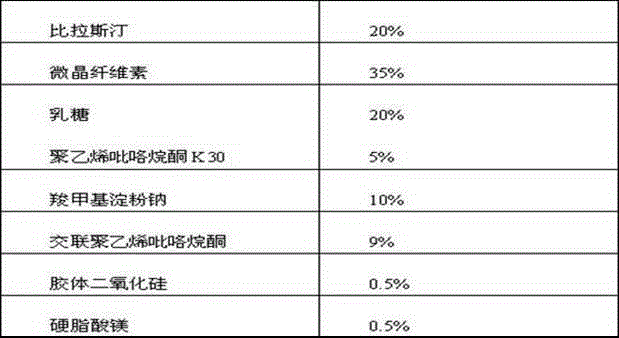

Embodiment 1

[0034]

[0035] Preparation process: This dosage form can be produced by conventional tablet pharmaceutical equipment and prepared by direct tableting process. The specific preparation method is as follows: the main drug is ground and passed through an 80-mesh sieve, and cross-linked carboxymethylcellulose sodium (CMC-Na) is passed through a 100-mesh sieve. Sieve, microcrystalline cellulose and lactose are respectively passed through 40 mesh sieves, respectively weighed according to the amount and then added to the main drug and mixed evenly, then the prescribed amount of magnesium stearate is added, sieved and mixed evenly, and the intermediate content is detected. After determining the weight of the tablet, the tablet is compressed by direct compression technology, and the product is obtained.

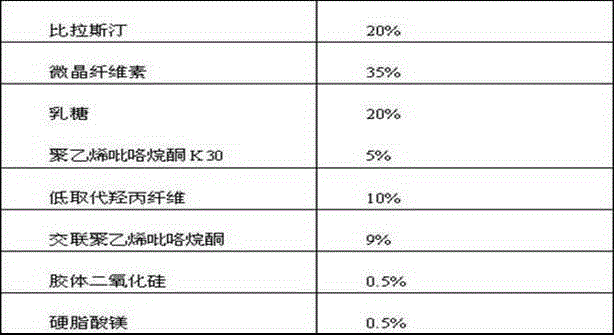

Embodiment 2

[0037]

[0038] Preparation process: This dosage form can be produced by conventional tablet pharmaceutical equipment and prepared by direct compression process. The specific preparation method is as follows: the main drug is ground and passed through an 80-mesh sieve, low-substituted hydroxypropyl cellulose is passed through a 100-mesh sieve, microcrystalline cellulose and The lactose is respectively passed through a 40-mesh sieve, weighed according to the amount and added to the main drug and mixed evenly, then the prescribed amount of magnesium stearate is added, sieved and mixed evenly, and the content of the intermediate is detected. After determining the weight of the tablet, the tablet is compressed by direct compression technology, and the product is obtained.

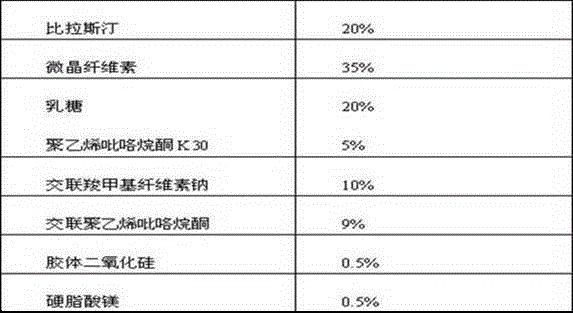

Embodiment 3

[0040]

[0041] Preparation process: This dosage form can be produced by using conventional tablet pharmaceutical equipment and prepared by dry granulation and tabletting process. The specific preparation method is as follows: pass the main drug, lactose, microcrystalline cellulose and cross-linked polyvinylpyrrolidone through a 100-mesh sieve, Weigh and add in sequence according to the amount, sieve and mix evenly, press into tablets, pass through a 18-mesh sieve for dry granulation. Then add the magnesium stearate of prescription quantity, sieve and mix, carry out intermediate content detection. After determining the weight of the tablet, it can be obtained by pressing the tablet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sheet weight | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com