A kind of preparation method of collagen film and collagen film

A collagen film and collagen technology, which is applied in the preparation of collagen film and in the field of collagen film, can solve the problems of loose collagen film and unsuitable dermis protective layer, etc., and achieve the effect of avoiding wound infection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

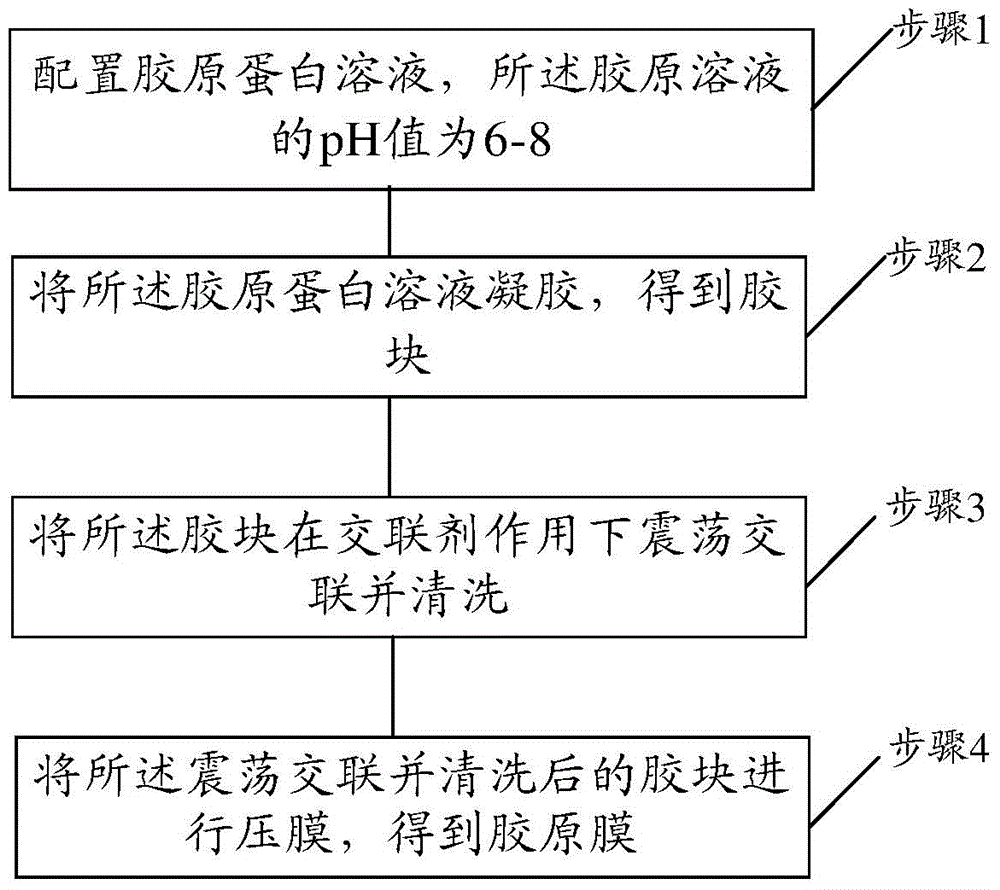

[0039] A kind of preparation method of collagen membrane provided by the embodiment of the present invention, see figure 1 ,include:

[0040] Step 1, configure collagen solution, the pH value of the collagen solution is 6-8;

[0041] Step 2, gelling the collagen solution to obtain a gel block;

[0042] Step 3, shaking and cross-linking the rubber block under the action of a cross-linking agent and cleaning;

[0043] Step 4. Pressing the vibrated, cross-linked and washed rubber block into a film to obtain a collagen film.

[0044] Through the above steps 1 and 4, the obtained collagen film is relatively dense and has suitable degradability, which can effectively protect the dermal matrix layer and avoid wound infection.

Embodiment 1

[0073] Collagen solution preparation: mix collagen with 0.05% acetic acid; put it in a refrigerator at 4°C for 48 hours to dissolve completely; add phenol red solution to the dissolved collagen solution under ice bath conditions, among which collagen The volume ratio of the protein solution to the phenol red solution is 100:1, and the pH value is adjusted to 6.5 with NaOH;

[0074] Gel: Put the configured collagen solution into the gel mold, and gel at a constant temperature of 37°C for 60 minutes to obtain gel blocks;

[0075] Cross-linking: under the action of EDC at a concentration of 50 mM, the gel blocks obtained from the gel were shaken and cross-linked at room temperature for 16 hours.

[0076] Film pressing: pressurize the rubber block for 10 minutes at a pressure of 1.0 kg / block, and then pressurize the block for 60 minutes at a pressure of 2.5 kg / block; wash the block with purified water for 5 times; Then according to the pressure of 3kg / rubber block, pressurize the...

Embodiment 2

[0079] Collagen solution preparation: mix collagen with 0.1% acetic acid; put it in a refrigerator at 6°C for 72 hours, and dissolve completely; add phenol red solution to the dissolved collagen solution in an ice bath, wherein collagen The volume ratio of the solution to the phenol red solution is 100:2, and the pH value is adjusted to 7 with NaOH;

[0080] Gel: Put the configured collagen solution into the gel mold, and gel at a constant temperature of 37°C for 50 minutes to obtain gel blocks;

[0081] Cross-linking: under the action of EDC with a concentration of 30 mM, the gel blocks obtained from the gel were shaken and cross-linked at room temperature for 36 hours.

[0082] Film pressing: pressurize the rubber block for 12 minutes at a pressure of 1.2 kg / block, and then pressurize the block for 60 minutes at a pressure of 3 kg / block; wash the block with purified water 4 times; then According to the pressure of 5kg / rubber block, it is enough to pressurize the cleaned rub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com